China Factory for Glasses To Goggles - Machinery & Equipment Inspections – TTS

China Factory for Glasses To Goggles - Machinery & Equipment Inspections – TTS Detail:

Product description

Quality control for machinery and equipment is critical for optimizing efficiency and improving your bottom line. Machinery and equipment inspections can be anything from a simple checklist inspection to one-off customized inspections, testing, and compliance verification checklists based on technical engineering requirements.

Our Inspection Services

Machinery Accessories

Factory Audit

Live Inspection

Testing

Loading Inspection

Machinery & Equipment Inspections

Factory Audit

Live Inspection & Production Supervision

Witness Testing

Loading/Unloading Supervision

Machinery Parts & Accessories Inspections

The processing technology and quality of machinery components and accessories determine the performance and safety of production machinery.

TTS has considerable experience in the industry. We perform technical inspections of the materials, appearance, usage, working condition, and function according to the production requirements.

Some of the machinery components we service include pipes, valves, fittings, castings, and forgings.

Machinery & Equipment Inspections

There is a significant variation of complexity in machinery configurations and operational principles. Our experienced technicians can evaluate your machinery based on accepted industry factors and your requirements to establish proper functionality, reliability of components and accessories, quality of assembly, and production results.

Manufacturing Equipment Inspections

Industrial Equipment Inspections

Constructions Equipment Inspections

Machinery & Equipment Inspections Services

Pressure vessels for chemical and food industry

Engineering equipment such as cranes, lifts, excavators, conveyor belts, bucket, dump truck

Mine and cement machinery including stacker-reclaimer, cement kiln, mill, machine of loading and unloading

Some services we provide include

Factory audit and evaluation: verify supplier business, technical and production capabilities, quality control systems and processes, and upstream supply chain.

Live inspection and production supervision: inspection and supervision refer to welding, nondestructive inspection, machinery, electrical, material, structure, chemistry, safety.

Physical inspection:current condition, dimensional specs, labels, instructions, documentation.

Functional inspection: safety and integrity of parts and the machinery, and lines layout.

Performance evaluation: whether the performance indicators meet design specifications.

Safety evaluation: reliability of safety features and function, verification of specs.

Certification Verification: verification of compliance with industry, regulatory, and certification body requirements.

loading/uploading inspection: at factory or port to monitor and verify techniques to ensure compliance with shipping and handling requirements.

Heavy Machinery & Equipment Inspections

Our experienced engineers and technicians evaluate and verify machinery based on accepted industry standards, regulatory compliance, certification verification, safety regulations, and business requirements. These may include upstream supply chain suppliers, the capability of components and accessories, quality of assembly, and production results.

Machinery & Equipment we provide quality control for

Road building and other heavy commercial construction machinery and equipment such graders and earth moving equipment

Agriculture, aquaculture, and forestry operations of all types

Transport and logistics including ocean, rail, and cargo handling equipment

Mining, chemical plants, cement plants, steel production and other heavy manufacturing machinery

Some services we provide include

Factory audit and evaluation: verify supplier business, technical and production capabilities, quality control systems and processes, and upstream supply chain

Live inspection and production supervision: inspection and supervision refer to welding, nondestructive inspection, machinery, electrical, material, structure, chemistry, safety

Physical inspection: current condition, dimensional specs, labels, instructions, documentation,

Functional inspection: safety and integrity of parts and the machinery, lines layout, etc.

Performance evaluation: whether the performance indicators meet design specifications

Safety evaluation: reliability of safety features and function, verification of specs

Certification Verification: verification of compliance with industry, regulatory, and certification body requirements

loading/uploading inspection: at factory or port to monitor and verify techniques to ensure compliance with shipping and handling requirements

Machinery & Equipment in China

TTS provides local quality assurance services in China dedicated to both safety, compliance, and quality optimization for factory systems and processes. We deliver quality assurance services according to regulatory, market, and client requirements.

How often should equipment and machinery be checked?

The answer varies considerably based on the type and usage of the equipment. At a minimum, inspections should be done based on manufacturer specifications.

What are the benefits of machinery and equipment inspections?

Regular equipment and machinery inspections help to ensure productivity, which is critical to your bottom line. Keeping equipment in good condition, running at peak performance, and operating with safety protocols in place maximizes efficiency and reduces loss.

The Quality Control Company You Can Trust

TTS has been in the quality assurance business for more than 10 years. Our services can equip you with the information you need when buying equipment for installation in Asia factories, or before shipping to other locations around the globe.

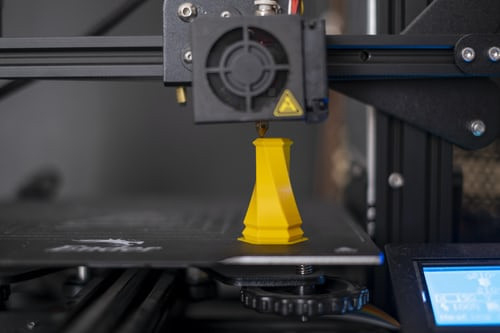

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for China Factory for Glasses To Goggles - Machinery & Equipment Inspections – TTS , The product will supply to all over the world, such as: Czech Republic , Vancouver , Oman , To get more information about us as well as see all our products, please visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.