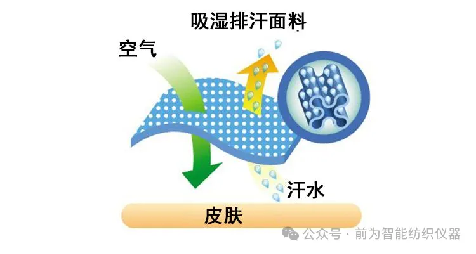

Yayin da yanayin ke daɗaɗaɗa kuma yanayin zafi ya tashi, tufafin su zama siriri kuma suna raguwa. A wannan lokacin, ƙarfin numfashi na tufafi yana da mahimmanci! Wani yanki na tufafi tare da ikon numfashi mai kyau zai iya kawar da gumi daga jiki yadda ya kamata, don hakanumfashi - iyawar masana'antayana da alaƙa kai tsaye da ta'aziyyar masana'anta.

Aikace-aikacen ikon numfashi a cikin masana'antar yadi

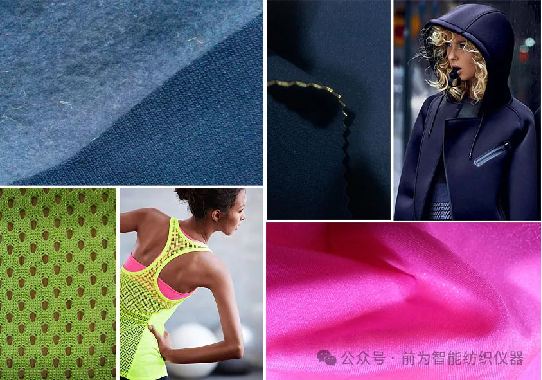

Masana'antar Tufafi: Ƙarfin numfashi yana ɗaya daga cikin mahimman alamomi don kimanta jin daɗin yadi. Musamman lokacin zayyana kayan wasan motsa jiki na waje, takalman wasanni da sauran samfuran, ya zama dole don tabbatar da ko za su iya samar da ikon numfashi mai kyau ta hanyar gwajin ikon numfashi don cimma shayarwar danshi da gumi. , Rike tasirin bushewa.

Tufafi na gida: kayayyaki irin su kayan kwanciya, labule, murfi, da dai sauransu. Ana iya amfani da gwajin yuwuwar iska don tantance yanayin iska na waɗannan samfuran sannan a kimanta jin daɗinsu da kuma amfani.

Kayayyakin magani: Kayan aikin likita kamar su rigunan tiyata da abin rufe fuska suna buƙatar samun ƙarfin numfashi don tabbatar da cewa ma’aikatan lafiya za su iya kasancewa cikin kwanciyar hankali a cikin yanayin aiki na dogon lokaci. Ta hanyar gwajin ƙarfin numfashi, ana iya ƙaddara aikin musayar gas na samfur don hana cututtukan ƙwayoyin cuta da ƙwayoyin cuta.

Kayan wasanni: Wasu kayan wasanni kamar takalman wasanni, hulunan wasanni, da sauransu kuma za su yi amfani da gwajin ƙarfin numfashi don tabbatar da aikinsu na zagayawa.

Aikace-aikacen ikon numfashi a cikin wasu masana'antu

Abubuwan sassa na mota na ciki: Ƙayyade ƙarfin iska da juriya na kayan sassa na motoci na ciki (kamar polyurethane, PVC, fata, yadi, yadudduka marasa saka, da sauransu).

Kayayyakin gini: Ƙayyade ƙarfin iska na kayan gini (kamar dutse, siminti, da sauransu) don kimanta ikonsu na shafar ingancin iska a cikin ginin.

Kayan marufi: Yawancin kayan marufi na musamman (kamar sabon marufi, da dai sauransu) suna buƙatar samun wani takamaiman matakin iyawar iska don tabbatar da ingancin abubuwan da ke cikin marufi.

Kayayyakin lantarki: Wasu ɓangarorin samfuran lantarki suna buƙatar samun kyakkyawan numfashi don tabbatar da aikin yau da kullun na kayan lantarki.

Kwatanta hanyoyin gwaji daban-daban don iyawar numfashi

Yanzu, akwai ma'auni da hanyoyin da yawa don gwajin ƙarfin ƙarfin masana'anta. Mai zuwa yana kawo muku matakan gwaji da kwatancen iyawar iska na yadudduka da aka saba amfani da su a gida da waje. Waɗannan ka'idoji sun fito ne daga ƙasashe ko ƙungiyoyi daban-daban, kamar ISO, GB, BS, ASTM, da sauransu. Ma'auni na mutum ɗaya na iya amfani da nau'ikan kayan ko samfura daban-daban, kamar waɗanda ba safai, yadi, da sauransu. Ma'auni daban-daban na iya amfani da ka'idodin gwaji daban-daban, kamar a matsayin hanyar kwararar iska, hanyar canja wurin tururin ruwa, da sauransu. Kodayake yawancin ma'auni suna amfani da ka'idodin gwaji iri ɗaya, takamaiman kayan gwajin na iya bambanta dangane da buƙatun ƙa'idar.

1.ISO 9073-15 ISO 9237

Iyakar aikace-aikacen: Ya dace da gwajin ƙyalli na iska na kayan da ba saƙa, kamar kayan tacewa, kayan rufewar zafi da sauran filayen. Ƙa'idar gwaji: Ana amfani da hanyar iska don auna yawan iskar gas ta hanyar samfurin don kimanta aikin ƙarfin numfashi. Kayan aiki na gwaji: Mai gwajin iska ya haɗa da tushen iska, na'urar gwaji, mita kwarara da sauran abubuwa.

2.GB/T 5453 GB/T 24218.15

Ƙimar aikace-aikacen: Ana amfani da shi don kimanta aikin ƙarfin numfashi na yadudduka, gami da yadudduka, sutura, da sauransu.

Ƙa'idar gwaji: Yi amfani da hanyar kwararar iska ko hanyar canja wurin tururin ruwa don auna yawan iskar gas ko tururin ruwa da ke wucewa ta cikin samfurin don kimanta aikin ƙarfin numfashi.

Kayan aikin gwaji: Hanyoyin gwaji daban-daban na iya buƙatar kayan aiki daban-daban. Misali, hanyar kwararar iska tana buƙatar kayan gwajin ƙarfin numfashi, kuma hanyar canja wurin tururin ruwa yana buƙatar kayan sarrafa zafi, da sauransu.

3. BS 3424-16 BS 6F 100 3.13

Ƙimar aikace-aikacen: Ana amfani da shi don kimanta aikin ƙarfin numfashi na yadudduka, kamar yadudduka, tufafi, da sauransu.

Ƙa'idar gwaji: Ana amfani da hanyar kwararar iska ko hanyar canja wurin tururin ruwa.

Kayan aikin gwaji: Ana iya buƙatar kayan aiki daban-daban bisa ga hanyoyin gwaji daban-daban. Misali, hanyar kwararar iska tana buƙatar kayan gwajin ƙarfin numfashi, kuma hanyar canja wurin tururin ruwa yana buƙatar kayan sarrafa zafi, da sauransu.

4. Saukewa: ASTM D737

Iyakar aikace-aikace: Ana amfani da shi musamman don kimanta aikin iya numfashi na yadudduka.

Ƙa'idar gwaji: Ana amfani da hanyar iska don auna yawan iskar gas ta hanyar samfurin don kimanta aikin ƙarfin numfashi.

Kayan aiki na gwaji: Mai gwajin iska ya haɗa da tushen iska, na'urar gwajin gwaji, mita kwarara, da sauransu.

5. JIS L1096 Abu 8.26 Hanyar C

Iyakar aikace-aikace: An yi amfani da shi sosai a cikin masana'antar yadin Jafan, galibi ana amfani da su don kimanta aikin iya numfashi na yadudduka.

Ƙa'idar gwaji: Ana amfani da hanyar kwararar iska don auna ƙarfin numfashi na yadudduka.

Kayan aiki na gwaji: Mai gwajin iska ya haɗa da tushen iska, na'urar gwajin gwaji, mita kwarara, da sauransu.

Daga cikin su, ana amfani da daidaitattun hanyoyin guda biyu, ISO 9237 da ASTM D737. GB/T 5453-1997 Wannan ma'auni ya shafi nau'ikan yadudduka iri-iri, gami da yadudduka na masana'antu, yadudduka marasa saƙa da sauran samfuran masaku masu numfashi. A yayin gwajin, masana'anta na tufafi da masana'anta an bambanta su da hankali ta hanyar raguwa daban-daban. Matsakaicin matsi na yadudduka ya kasance 100Pa, kuma matsa lamba na yadudduka na masana'antu shine 200Pa. A GB / T5453-1985 "Hanyoyin Gwajin Numfashin Fabric-ability Test", da iska permeability (yana nufin ƙarar iska da ke gudana ta cikin yanki na masana'anta a kowane lokaci naúrar ƙarƙashin ƙayyadaddun bambancin matsa lamba a bangarorin biyu na masana'anta) ana amfani da shi don auna karfin iska na masana'anta. Ƙididdigar GB / T 5453-1997 da aka sake dubawa yana amfani da karfin iska (yana nufin adadin iskar da ke wucewa a tsaye ta hanyar samfurin a ƙarƙashin yankin samfurin da aka ƙayyade, raguwar matsa lamba da yanayin lokaci) don bayyana yanayin iska na masana'anta.

ASTM D737 ya bambanta da ma'auni na sama dangane da kewayon aikace-aikacen, zafin jiki da zafi, wurin gwaji, bambancin matsa lamba, da sauransu. takamaiman zazzabi da zafi, yankin gwaji, bambancin matsa lamba da sauran yanayi na ISO 9237 da ASTM D737, zaɓi dacewa da yanayin wakilci, da kafa ƙa'idodin masana'antu masu dacewa don shigo da kaya da fitarwa.

Kwatancen sakamakon gwajin

Sakamakon iya numfashi na masana'anta yana da alaƙa kusa da hanyar gwaji da aka yi amfani da ita. Daga cikin sakamakon gwajin da aka samu ta amfani da ma'auni daban-daban guda hudu: ISO 9237, GB/T 5453, ASTM D 737 da JIS L 1096: iskar da aka gwada bisa GB/T 5453 da ISO 9237 iri daya ne; bisa ga GB/T5453 (ISO 9237)) Ƙwararren iska da aka gwada shi ne mafi ƙanƙanta; karfin iska da aka gwada bisa ga JIS L1096 shine mafi girma; ikon iskar da aka gwada bisa ga ASTM D737 yana tsakiyar. Lokacin da wurin gwajin ya kasance baya canzawa, haɓakar iska yana ƙaruwa yayin da raguwar matsa lamba ya karu, wanda ya dace da raguwar matsa lamba yana ƙaruwa da yawa. A taƙaice, kawai ta zaɓin hanyoyin gwaji masu dacewa dangane da halayen samfur ne za'a iya ƙididdige numfashin yadudduka daidai.

Cikakken bayani na matakan gwaji (ɗaukar GB/T 24218-15 a matsayin misali)

Ana ƙididdige samfurin bisa ga ƙa'idodin samfur ko shawarwari tare da masu dacewa. Don kayan gwaji waɗanda za su iya gwada manyan yadudduka masu girma kai tsaye, aƙalla sassa 5 na masana'anta masu girma dabam za a iya zaɓar su ba da gangan azaman samfuran gwaji; don kayan aikin gwaji waɗanda ba za su iya gwada samfurori masu girma ba, ana iya amfani da ƙirar yanke ko samfuri (Yanke aƙalla samfuran 5 na girman 100mmX100 mm).

Sanya samfurin daga mahalli na yau da kullun zuwa daidaitaccen yanayi na yanayi wanda ya dace da GB/T6529 kuma daidaita zafi zuwa daidaito.

Rike gefen samfurin don gujewa canza yanayin wurin gwajin mara saƙa.

Sanya samfurin akan kan gwajin kuma gyara shi tare da tsarin matsewa don hana karkatar da samfurin ko zubar iskar gas a lokacin gwajin. Lokacin da akwai bambanci a cikin iska tsakanin gaba da baya na samfurin, ya kamata a lura da gefen gwajin a cikin rahoton gwaji. Don samfurori masu rufi, sanya samfurin tare da gefen da aka rufaffen ƙasa (zuwa ƙananan matsa lamba) don hana zubar da iskar gas.

Kunna injin famfo kuma daidaita yanayin kwararar iska har sai an kai ga bambancin matsa lamba da ake buƙata, wato 100Pa, 125Pa ko 200Pa. A kan wasu sabbin kayan aikin, ana zaɓe ƙimar gwajin gwajin ta hanyar lambobi, kuma ana nuna bambancin matsa lamba a bangarorin biyu na buɗaɗɗen ma'aunin a lambobi cikin rukunin gwajin da aka zaɓa don sauƙaƙe karatun kai tsaye.

Idan an yi amfani da ma'aunin matsi, jira har sai ƙimar da ake buƙata ta tsaya tsayin daka sannan karanta ƙimar iskar da ke cikin lita a cikin murabba'in centimita [L/(cm·s)].

Lokacin aikawa: Mayu-06-2024