A lokacin da ake sawa, tufafin suna fuskantar kullun da rikici da sauran abubuwan waje, suna haifar da samuwar gashi a saman masana'anta, wanda ake kira fluffing. Lokacin da ƙullun ya wuce 5 mm, waɗannan gashin gashi / zaren za su haɗu da juna don samar da ƙwallo marasa daidaituwa, wanda ake kira pilling.

01Me yasa yake yin kwaya?

Yayin da masana'anta ke ci gaba da gogewa yayin amfani da su, a hankali ƙwallan fiber ɗin suna kusanta, kuma filayen da ke da alaƙa da masana'anta suna ta lanƙwasa akai-akai, sun gaji, har ma sun karye a wurare daban-daban. Ƙwayoyin fiber suna faɗo daga saman masana'anta, amma gashin fiber a ƙarshen karya zai kasance bayan haka. Yayin amfani da su ana ci gaba da fitar da su kuma a sake yin ƙwallan fiber.

Gabaɗaya magana, zaruruwan ulu da zaruruwan sinadarai suna da yuwuwar yin kwaya, musamman yadudduka masu kati ko yadudduka masu kama da ulu da yadudduka na cashmere. Daga hangen nesa na yarn da tsarin nama, ƙuƙwalwar yarn yana da ƙananan, gashin gashi yana da girma, tsarin masana'anta yana kwance, kuma twill da satin yadudduka tare da dogon layi na iyo suna da wuya ga pilling.

Bugu da ƙari, ta fuskar tsarin sarrafawa, gabaɗaya murɗaɗɗen fiber yana da girma, haɗin kai tsakanin zaruruwa yana da girma, kuma tsarin masana'anta yana da ɗan tsauri da santsi, don haka ba shi da sauƙin yin kwaya. Akasin haka, al'amarin pilling ya fi tsanani a cikin yadudduka da aka haɗa, musamman nailan, polyester, polypropylene, da dai sauransu. Wannan ya faru ne musamman saboda yadudduka da aka haɗa suna da maɓalli daban-daban tsakanin zaruruwa, kuma saman masana'anta yana da wuyar samun lint.

02Yadda ake gwada kwaya?

Domin tabbatar da aminci da kwanciyar hankali na tufafi ko yadin da aka yi amfani da su, za a gwada masana'anta don aikin kwaya kafin a sanya su cikin samfuran da aka gama ko kuma bayan an gama suturar.

Matsayin hanyar gwajidomin kwayayen sutura da kayan masaku sune:

GB/T 4802.1-2008 "Hanyar da'ira"

GB/T 4802.2-2008 "Dokar Martindale Gyara"

GB/T 4802.3-2008 "Hanyar Akwatin Kwalli"

GB/T 4802.4-2020 "Tsarin Tumbling Random"

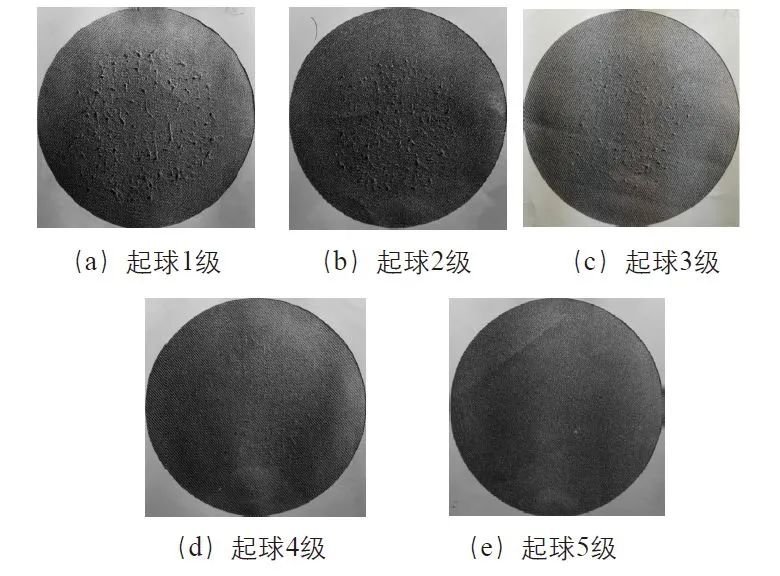

Ko da yake duk sun gwada matakin pilling na yadudduka, hanyoyin da ke sama sun dace da yadudduka na tufafi daban-daban kuma ka'idodin aiki na kayan aiki ma sun bambanta. Aikin pilling da aka gwada ana bayyana shi ne a sigar maki, wanda gabaɗaya an raba shi zuwa maki 1 zuwa na 5. Girman daraja, ƙananan yuwuwar suturar za ta iya yin kwaya. Ma'auni na gaba ɗaya yana ƙayyadaddun cewa ma'aunin ≥ matakin 3 ingantaccen samfur ne.

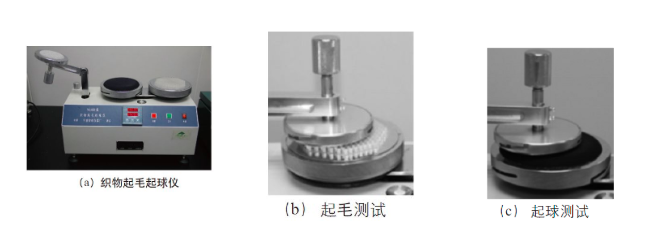

Ka'idar GB/T 4802.1-2008 "Hanyar da'ira" ita ce, ana shafa samfurin tare da goga nailan da ƙyallen masana'anta ko kawai tare da abrasive masana'anta don ƙayyadadden adadin lokuta a ƙarƙashin ƙayyadadden matsa lamba don haifar da kwaya a saman samfurin.

Wannan hanyar tana da saurin gwaji mai sauri kuma tana iya yin kwatankwacin juzu'i da ɗigon masana'anta bayan an haɗa su. Ya dace da yadudduka da aka saka da kayan saƙa kamar su sweatshirts da T-shirts.

Ɗaukar GB/T 4802.1-2008 "Hanyar Dabaru" don gwada ƙwayar yadudduka a matsayin misali, Hoto 2 hoto ne na samfurin masana'anta na fiber na sinadarai tare da matakan pilling 1 zuwa 5.

Hoto 1 Hanyar da'ira mai da'ira da kayan aiki da tsarin gwaji

Hoto 2 Misalin matakin kwayayen samfurin

2.2Hanyar Martindale da aka gyara

Ka'idar GB/T 4802.2-2008 "Hanyar Gyaran Martindale" ita ce a ƙarƙashin ƙayyadaddun matsa lamba, samfurin madauwari yana juyawa da yardar kaina a kusa da tsakiyar axis perpendicular zuwa jirgin samfurin, kuma yanayin siffar Lissajous ya dace da masana'anta iri ɗaya. ko kuma ana amfani da abrasives masana'anta na ulu don rikicewa, wanda ya dace da gwajin nau'in gado.

Hoto 3 Mai gwadawa Martindale pilling

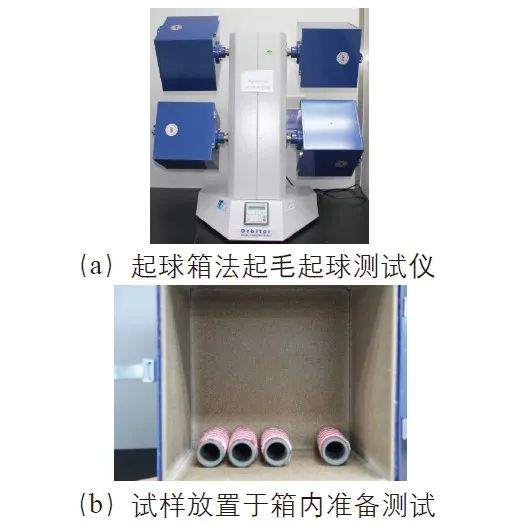

Ka'idar GB/T 4802.3-2008 "Tsarin Akwatin Kwakwalwa" shine: an shigar da samfurin a kan bututun polyurethane kuma an juya shi ba tare da izini ba a cikin akwati na katako wanda aka yi da abin toshe kwalaba tare da saurin juyawa akai-akai. Bayan ƙayyadadden adadin juzu'i, ana siffanta abubuwan da ke damun su da/ko a gani da tantance su. Ya dace da gwajin kayan sakawa.

Hoto 4 Hanyar kwalin kwalin gwajin gwaji da jeri samfurin

Ka'idar GB/T 4802.4-2020 "Hanya bazuwar Tumbling" ita ce a yi amfani da akwatin tumbling bazuwar don sa masana'anta suyi rugujewa da gogewa ba tare da izini ba a cikin dakin gwaji na silinda wanda aka lullube shi da abin togiya kuma an cika shi da ɗan gajeren auduga mai launin toka. . Ka'idodin samfuran tufafin cikin gida ba su kawo wannan hanyar ba tukuna.

Hoto 5 Mai gwada hanyar tumbling bazuwar

Kariyar gwaji: Lokacin da aka aika samfuran da ba tufafi ba don dubawa, gefen gaba lokacin da aka yi amfani da shi dole ne a yi alama don guje wa kurakuran gefen gwaji. Don combing, carding, da sauransu waɗanda ke da buƙatun siga daban-daban, ya kamata a kula da zaɓin siga.

Lokacin aikawa: Janairu-23-2024