Katifa masu dadi suna da tasirin inganta ingancin barci. Ana yin katifu da abubuwa daban-daban, kamar dabino, roba, maɓuɓɓugan ruwa, latex da sauransu. Dangane da kayansu, sun dace da ƙungiyoyin mutane daban-daban. A lokacin da masu dubawa ke duba katifa daban-daban, ya kamata su gudanar da bincike a kan wane bangare kuma su ba da kulawa ta musamman ga duk wani lahani. Editan ya taƙaita muku abubuwan da ke cikin binciken katifa kuma ya ga yana da amfani kuma ana iya tattarawa!

Matsayin dubawa na samfur da marufi 1. Samfur

1) dole ne a sami matsala ta aminci yayin amfani

2) Tsarin tsari dole ne ya kasance ba tare da lalacewa ba, raguwa, fasa, da dai sauransu.

3) Dole ne ta bi dokoki da ƙa'idodin ƙasar da ake nufi da buƙatun abokin ciniki

4) Tsarin samfurin, bayyanar, tsari, da kayan aiki dole ne su hadu da bukatun abokin ciniki da samfurori na tsari

5) Dole ne samfurin ya cika buƙatun abokin ciniki ko ayyuka iri ɗaya kamar samfuran tsari

6) Dole ne alamar alamar ta kasance a bayyane kuma ta bi ka'idodin doka da ka'idoji

1) Marufi dole ne ya dace kuma yana da ƙarfi don tabbatar da amincin tsarin sufurin samfur.

2) Dole ne kayan tattarawa su iya kare jigilar kayayyaki.

3) Alamomin jigilar kaya, lambobin barcode, da alamun ya kamata su dace da buƙatun abokin ciniki ko samfuran tsari.

4) Kayan marufi yakamata ya dace da buƙatun abokin ciniki ko samfuran tsari.

5) Rubutun bayani, umarni, da gargaɗin alamar da ke da alaƙa dole ne a buga su a fili cikin yaren ƙasar da aka nufa.

6) Bayanin umarnin dole ne ya kasance daidai da samfurin da ainihin ayyukan da suka dace

1) Ma'auni na dubawa: ISO 2859 / BS 6001 / ANSI / ASQ-Z 1.4 Tsarin Samfurin Samfurin Guda, Binciken Al'ada.

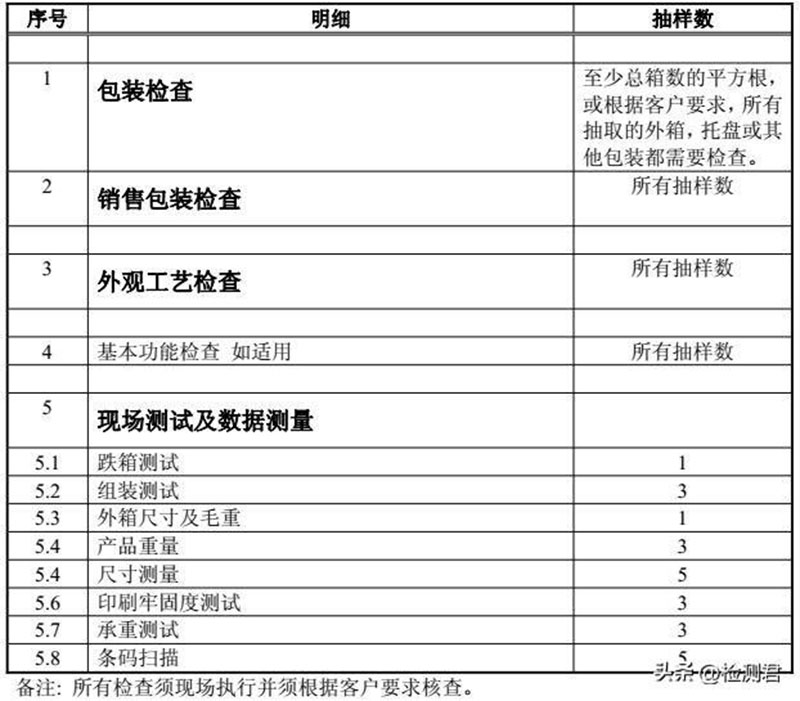

2) Matsayin Samfura: Da fatan za a koma zuwa lambobi masu ƙima a cikin tebur mai zuwa

3) Idan samfura da yawa sun haɗe don dubawa, ana ƙididdige adadin samfurin kowane samfur ta yawan adadin wannan samfurin a cikin duka tsari. Yi lissafin adadin samfurin wannan samfurin daidai gwargwado dangane da yawan abin da aka shagaltar da shi. Idan lambar samfurin da aka ƙididdige ta ƙasa da 1, za a ɗauki samfurori guda biyu a matsayin samfurin batch gaba ɗaya, ko kuma a ɗauki samfurin ɗaya azaman gwajin matakin samfur na musamman.

3) Idan samfura da yawa sun haɗe don dubawa, ana ƙididdige adadin samfurin kowane samfur ta yawan adadin wannan samfurin a cikin duka tsari. Yi lissafin adadin samfurin wannan samfurin daidai gwargwado dangane da yawan abin da aka shagaltar da shi. Idan lambar samfurin da aka ƙididdige ta ƙasa da 1, za a ɗauki samfurori guda biyu a matsayin samfurin batch gaba ɗaya, ko kuma a ɗauki samfurin ɗaya azaman gwajin matakin samfur na musamman.

4) Matsayin ingancin da aka yarda da shi AQL: Babu wani lahani mai mahimmanci da aka ba da izini Mahimmin lahani AQL xx Babban lahani AQL xx Ƙananan ma'auni bayanin kula: "xx" yana wakiltar daidaitattun matakin ingancin da abokin ciniki ke buƙata.

5) Yawan samfuran samfuri na musamman ko ƙayyadaddun samfur, Ba a yarda da daidaituwa ba.

6) Gabaɗaya sharuɗɗa don rarraba lahani: (1) Muhimmin Lalacewa: Lalacewar da ke haifar da rauni na mutum ko abubuwan da ba su da aminci yayin amfani ko adana kayayyaki, ko lahani waɗanda suka keta dokoki da ƙa'idodi masu dacewa. (2) Manyan lahani Laifukan aiki suna shafar amfani ko tsawon rayuwa, ko bayyananniyar lahani yana shafar ƙimar siyar da samfur. (3) Ƙananan lahani lahani ne waɗanda basu shafi amfani da samfurin ba kuma basu da alaƙa da ƙimar siyar da samfurin.

7) Dokokin binciken bazuwar: (1) Binciken ƙarshe yana buƙatar cewa aƙalla 100% na samfuran an samar da su kuma an shirya su don siyarwa, kuma aƙalla 80% na samfuran an tattara su cikin akwatuna na waje. Ban da buƙatu na musamman daga abokan ciniki. (2) Idan an sami lahani da yawa akan samfurin, ya kamata a rubuta mafi girman lahani a matsayin tushen yanke hukunci. Dole ne a maye gurbin ko gyara duk lahani. Idan an sami lahani mai tsanani, yakamata a ƙi duk rukunin kuma abokin ciniki ya yanke shawarar ko zai saki kayan.

4. Tsarin dubawa da rarraba lahani

Cikakkun bayanai na lambar serial, rarrabuwar lahani CriticalMajorMinor1) Binciken marufi, buɗe jakar filastik> 19cm ko yanki> 10x9cm, babu alamun faɗakarwa da aka buga, alamun faɗakarwar aminci X sun ɓace ko bugu mara kyau, alamun bayanin X sun ɓace ko bugu mara kyau, Yaren X na ƙasar da aka nufa , Asalin asalin X ya ɓace, Sunan mai shigo da X da adireshin da ya ɓace ko bugu mara kyau, Matsalar alamar X ko zane: ɓacewar abun ciki, kuskure Tsarin, Haɓaka gefuna da maki masu kaifi akan marufi, irin su X, sun lalace, fashe, gurɓatacce, da ƙazanta, kayan XX ba daidai ba ko kayan marufi da ba daidai ba kamar tabo ko dampness X marufi X ba a sani ba bugu X fakitin fakitin baya biyan bukatun abokin ciniki Marufi na katako X ba ya biyan buƙatun ƙa'ida Rataye braket X bacewar zare ko wasu kayan haɗin X bacewar na'urorin haɗi X Lalacewar jakar filastik X jakar filastik Kuskuren X wari X mold X damp XX taken gargaɗin tsaro ya ɓace ko bugu Rasa ko maras tabbas X taken faɗakarwa

3) Bayyanar da kuma tsarin dubawa

Coil tare da haɗarin rauni X kaifi baki X allura mai kaifi ko ƙarfe baƙin ƙarfe X ƙananan sassa a cikin kayan yara X ƙamshi na musamman X kwari masu rai X tabon jini X ya ɓace a hukumance ƙasar da aka nufa X bacewar wurin asali X karye yarn X karye zaren X roving XX launi yarn XX kadi XX babban ciki yarn XX auduga kulli XX allura biyu X fashe rami X masana'anta lalacewa X tabo XX mai tabo XX tabon ruwa XX bambancin launi XX fensir alamar XX manne alama XX zaren shugaban XX al'amarin waje XX bambancin launi X fading X matalauta ironing XX matsawa nakasawa X matsawa tashin hankali X crease XX crease XX m gefen XX Broken Zare X Fadowa Ramin X Tsalle Zare XX Nadawa Zaren XX mara daidaituwa Zaren XX Wave Allura XX a hankali dinki X mara kyaun dawowar allura X Bacewar Kwanan wata X Misalign kwanan wata X Bacewar Ɗakin X Misalign ɗinka na Kabu X Kwanciyar Kwanciyar Hankali X Sako da Zaren ɗinki X Allura Haƙori Mark XX Ruɗe Zare XX Fashe Crack X Wrinkled Zaren XX Twisted Seam X Sako Kabu/Baki X Nada Kabu X Misalignment na Kabu Narke Jagora X Seam Slip X Seam Misalignment X Misalignment X Seam Misalignment X Seam Misalignment X Seam Misalignment X Bacewar Salon XX Misalignment X Karshe Zaren Tushen XX Misalignment na Zaren Salon XX Misalign. Kuskuren bayanin lakabin Elevator X bayanin lakabin Elevator Kuskuren bugu XX Alamar Elevator ta toshe alamar XX Elevator alama ba amintacce tambarin XX gaba da baya misalignment X skewed lakabin XX4) Zipper dubawa aiki, maɓalli, maɓalli huɗu, rivet, Malfunction na Velcro da sauran abubuwan da aka gyara X Uneven zipper function XX

5. Ma'auni na bayanai da gwajin kan-sitena gwajin akwatin ISTA IA. Idan an sami gazawar aminci da aiki ko lahani mai mahimmanci, za a ƙi duk rukunin gwajin taro. Za a haɗa samfurin bisa ga umarnin kuma an daidaita shi da nau'in gado mai dacewa don tabbatar da cewa kayan haɗi sun cika, umarnin taro ya bayyana, kuma aikin samfurin bayan an gama haɗuwa. Girman da nauyin dukkanin kwalayen wutsiya dole ne a daidaita su tare da bugu na waje, tare da haƙuri na ± 5%. Binciken nauyi zai dogara ne akan bukatun abokin ciniki, kuma idan babu buƙata, Ƙayyade haƙuri na ± 3%. Karɓar cikakken binciken girman tsari. Dangane da bukatun abokin ciniki, idan babu buƙatu, yi rikodin ainihin girman da aka samo. Karɓar duka rukunin bugu don tabbatarwa. Yi amfani da jakunkuna na filastik 3M 600 don gwaji, kuma idan akwai ɓarna. 1. Yi amfani da jakunkuna na filastik 3M don manne wa firinta kuma danna da ƙarfi don digiri 2.45 don yaga tef ɗin. 3. Bincika idan akwai detachment na bugu akan tef da bugu. Karɓar duka rukunin gwajin ɗaukar nauyi. Sanya diski mai ɗaukar kaya (diamita 100MM a cikin da'irar) a tsakiya kuma yi amfani da ƙarfin 1400N, Ci gaba da kasancewa na minti 1, samfurin ya kamata ya zama mara lahani, fashe, kuma har yanzu ana iya amfani da shi kullum kamar yadda ake buƙata. Yakamata a yi watsi da duka rukunin lambobin sirri. Bincika lambobin barcode ta amfani da na'urar daukar hotan takardu don karanta barcode, kuma duba idan lambobi da ƙimar karatun sun daidaita. Hukuncin duk lahani don tunani ne kawai. Idan abokin ciniki yana da buƙatu na musamman, yakamata hukuncin ya dogara da buƙatun abokin ciniki.

Lokacin aikawa: Mayu-11-2023