KEMA-KEUR alama ce ta aminci da aka fi sani da ita a cikin lantarki, lantarki, da masana'antar samfuran kayan aikin.

ENEC alamar tabbatarwa ce ta aminci wacce za ta iya maye gurbin ƙasashe daban-daban na EU a cikin masana'antar samfuran lantarki, lantarki, da kayan haɗin gwiwar Turai.

CB takardar shedar ce da aka bayar bisa ma'aunin IECEE (International Electrotechnical Commission).

Ƙungiyoyin takaddun shaida na ƙasashe membobin IECEE suna gwada amincin samfuran lantarki bisa ka'idodin IEC, kuma sakamakon gwajin su, wato rahotannin gwajin CB da takaddun shaida na CB, ƙasashen membobin IECEE ne suka amince da juna.

Manufar gudanar da gwajin CB shine don rage farashin gwajin da ba dole ba saboda maimaita gwaji. Abokan ciniki suna buƙatar gwada sau ɗaya kawai don samun takaddun samfur daga cibiyoyin ƙasa na CB.

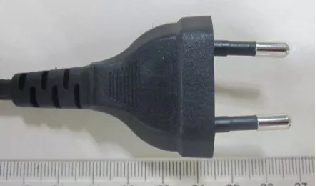

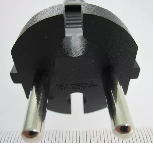

Menene manyan nau'ikan matosai da kwasfa da abin ya shafa?

Babban nau'ikan matosai na gida a Turai

1 Salon Turai

(2.5A, toshe na duniya a Turai)

2 Jamusanci Faransanci (Jamus, Netherlands, Norway, Sweden, Finland, Denmark, Spain, Austria, Italiya, da dai sauransu)

3 Italiya

4 Switzerland

5 Burtaniya (Birtaniya, Ireland)

Matsayin Turaidon gwada matosai na gida

1, Netherlands - NEN 1020:1987 + A2:2004

2, Faransa - NF C61-314: 2017

3, Jamus - DIN VDE 0620-2-1: 2016 + A1: 2017

4, Belgium - NBN C 61-112-1:2017

5, Norway - NEK IEC 60884-1: 2002 + A1: 2006 + A2: 2013 + NEK 502: 2016

5, Ostiraliya - ÖVE/ÖNORM E 8684-1:2010 + ÖVE/ÖNORM E 8620-3:2012

6, Finland - SFS 5610:2015 + A11:2016

7, Denmark - DS 60884-2-D1: 2017

8, Sweden - SS-IEC 60884-1: 2013 + SS 4280834: 2013

9, Italiya - CEI 23-50:2007 + V1:2008 + V2:2011 + V3:2015 + V4:2015

10, Spain - UNE 20315-1-1:2017 + UNE 20315-1-2:2017

11, SEV 1011:2009+A1:2012

12, Ƙasar Ingila: BS1363-1: 2016+A1: 2018

Kariya ga turawa gida matosai

1. Don samfuran da ba za a iya maye gurbinsu ba, tsayin igiyar wutar lantarki yana da buƙatu masu zuwa:

——Filogi ya zo da igiyar wutar lantarki 0.5mm2, wacce ke iya kaiwa iyakar tsayin mita 2 kawai

--16A filogi tare da igiyar wutar lantarki 1.0mm2, matsakaicin tsayin waya zai iya kaiwa 2m kawai

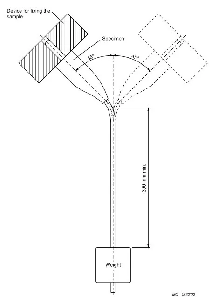

2.Swinging igiyar wuta

(1) An karye gaba ɗaya a lanƙwasa (wataƙila a wuri ɗaya ko ɗan warwatse), ko kuma tare da raguwar adadin da ya wuce ƙayyadaddun ƙayyadaddun ƙayyadaddun: wannan lamari ne na kowa, kuma wuraren karya galibi suna kasancewa a mafi raunin sassa na tsarin. Idan hannu ɗaya ya riƙe filogi, ɗayan kuma ya ja wayar, wurin da mafi ƙarancin lanƙwasa radius zai iya karye. Wuraren da aka yi hutun sun ɗan warwatse, sau da yawa saboda kasancewar grid a ƙarshen hanyar sadarwa, ko grid ɗin da ke haɗuwa kuma ba daidai ba ne, don haka hutun ba dole ba ne maki ɗaya, amma maki da yawa. Amma yawanci yana kusa sosai!

(2) Ya karye a wurin riveting, wanda ƙila ba ku lura ba: wannan ya faru ne saboda wuce gona da iri, yana haifar da lahani ga mai gudanarwa. Duk da haka, lokacin lanƙwasawa, madugu a zahiri yana faɗaɗa kuma yana yin kwangila a cikin rufin, yana haifar da yuwuwar ɓarke cikakkiyar ko ɓarna a wurin riveting ba tare da karyewa a wurin lanƙwasawa ba. Ana iya gani a fili ta hanyar rarrabawa. Ya kamata a mai da hankali ga rarrabawa, kuma filogi ya kamata a mai zafi kuma a kula da shi a hankali. Wannan yanayin kuma ya zama ruwan dare ga masana'antun da ba a sarrafa ingancin riveting.

(3) Kumburi ya zame, kuma ana iya ganin ainihin waya: wannan ya faru ne saboda rashin isasshen zafin jiki da kuma matsa lamba a lokacin da ake samar da filogi don haɗa PVC da kullin waya, musamman ga manyan sheaths ko sheath na roba (wanda ba zai iya ba. a hade kwata-kwata), don haka ƙarfin haɗin kai tsakanin kube da filogi bai isa ba, yana haifar da ƙaura da zamewa idan an lanƙwasa akai-akai.

(4) Rushewar rufewa na iya bayyana mai gudanarwa: Akwai dalilai guda uku na wannan yanayin: na farko, rufin yana rushewa a ƙarƙashin lankwasawa akai-akai; Dalili na biyu shi ne, PVC a wutsiyar filogi ya karye, kuma ramin yaga ya ci gaba da tsawaita, yaga abin rufe fuska shima; Na uku, wayar tagulla ta karye ta huda rufin.

(5) Karyewar wutsiya mai toshe: Kayan kayan roba mara kyau ko ƙirar grid mara kyau na iya haifar da nakasar wuce kima ko damuwa, yana haifar da karyewar wutsiyar filogi!

(6) Rubutun huda madugu da fallasa: Bangaren lanƙwasa na madugu yana karyewa, yana sa rufin ya zama siriri a ƙarƙashin damuwa. Wayar tagulla a wurin karyewar na iya fitowa daga rufin, har ma da masu gudanar da polarities daban-daban na iya haɗuwa, suna haifar da baka.

Shirin Gwaji da Takaddun Shaida

1. Takardun da ake buƙata kafin zance

——Bayanin aikace-aikacen (sunan kamfani da kasuwar da ake fitar da kayayyakinsa)

—— Sunan samfur da ƙirar, bayanin bambance-bambance tsakanin samfuran samfuri dole ne a samar da samfuran jerin samfuran

——Ainihin sigogi na lantarki, kamar ƙimar halin yanzu da tantance farantin suna

——Tsarin tsarin samfur ko hotuna, da sauransu

2. Bayanai na asali don shawarwarin aikin

——Takardu irin su fom ɗin aikace-aikacen, maganganun da aka sa hannu, da sauransu

--Bayanin asali na samfurin, gami da jerin abubuwan BOM; Tambarin sunan samfur; Tsarin tsari, da sauransu

——Aika samfurori

3. Bibiyar aiki akan aikin

——Bayan shigar da ƙarar, akwai sabis na abokin ciniki da aka sadaukar da injiniyoyi da ke da alhakinsa

——Gwaji da tabbatarwa

Lokacin aikawa: Satumba-04-2024