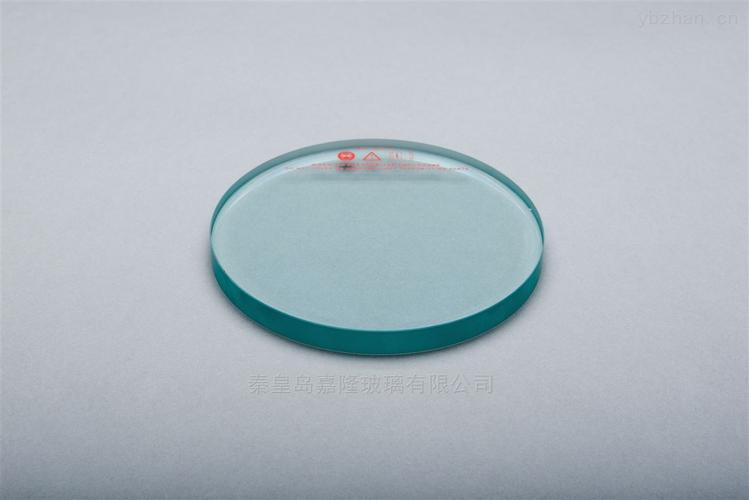

Tempered iav yog iav nrog compressive kev nyuaj siab ntawm nws nto. Kuj tseem hu ua reinforced iav. Siv txoj kev tempering los txhawb cov iav.

Tempered iav belongs rau iav kev nyab xeeb. Tempered iav tiag tiag yog hom prestressed iav. Txhawm rau txhim kho lub zog ntawm iav, tshuaj lom neeg los yog lub cev txoj kev feem ntau yog siv los tsim kev ntxhov siab rau ntawm lub khob. Thaum lub iav raug rau sab nraud quab yuam, nws thawj zaug offsets saum npoo kev nyuaj siab, yog li txhim kho nws cov load-bearing muaj peev xwm, txhim khu nws tus kheej cua siab tsis kam, txias thiab kub tsis kam, cuam tshuam tsis kam, thiab lwm yam. Ua tib zoo saib xyuas qhov txawv ntawm fiberglass.

Cov yam ntxwv ntawm tempered iav:

Kev ruaj ntseg

Thaum iav raug puas tsuaj los ntawm sab nraud quab yuam, cov fragments yuav tsim me me blunt lub kaum sab xis zoo li cov duab honeycomb, uas tsis tshua muaj yuav ua rau mob loj rau tib neeg lub cev.

siab zog

Qhov cuam tshuam lub zog ntawm tempered iav nrog tib tuab yog 3-5 npaug ntawm cov iav zoo tib yam, thiab lub zog khoov yog 3-5 npaug ntawm cov iav zoo tib yam.

thermal stability

Tempered iav muaj qhov zoo thermal stability, tuaj yeem tiv taus peb zaug qhov sib txawv ntawm qhov kub ntawm cov iav zoo tib yam, thiab tuaj yeem tiv taus qhov kub thiab txias hloov ntawm 300 ℃.

Qhov zoo

Thawj yog tias lub zog yog ob peb zaug siab dua li cov iav zoo tib yam, thiab nws yog resistant rau dabtsi yog khoov.

Qhov thib ob yog kev nyab xeeb nyob rau hauv kev siv, raws li nws load-bearing muaj peev xwm nce thiab txhim kho nws fragility. Txawm hais tias tempered iav puas lawm, nws zoo nkaus li me me shards yam tsis muaj cov ces kaum ntse, zoo heev txo kev puas tsuaj rau tib neeg lub cev. Kev tiv thaiv ntawm tempered iav kom txias txias thiab cua sov yog 3-5 npaug siab dua li cov iav zoo tib yam, thiab feem ntau nws tuaj yeem tiv taus qhov kub ntawm qhov sib txawv ntawm ntau tshaj 250 degrees, uas muaj cov txiaj ntsig tseem ceeb ntawm kev tiv thaiv thermal tawg. Nws yog hom iav kev nyab xeeb. Txhawm rau kom muaj kev nyab xeeb ntawm cov khoom tsim nyog rau cov tsev siab.

Ua tsis tau

Disadvantages ntawm tempered iav:

1.Tempered iav tsis tuaj yeem txiav ntxiv lossis ua tiav, thiab tsuas yog tuaj yeem ua tiav rau cov duab xav tau ua ntej tempering.

2.Txawm hais tias cov iav tempered muaj lub zog ntau dua li cov iav zoo tib yam, nws muaj peev xwm ua rau nws tus kheej tawg (tus kheej tawg), thaum lub iav zoo tib yam tsis muaj qhov ua rau nws tus kheej tawg.

3.Qhov saum npoo ntawm tempered iav yuav muaj qhov tsis sib xws (cua me ntsis) thiab me ntsis thinning ntawm thickness. Yog vim li cas rau thinning yog tias tom qab lub iav yog softened los ntawm kub melting, nws yog ceev ceev txias los ntawm cov cua muaj zog, ua rau cov crystal gaps nyob rau hauv lub khob kom txo thiab lub siab nce. Yog li ntawd, lub iav yog thinner tom qab tempering dua ua ntej. Feem ntau, 4-6mm iav ua 0.2-0.8mm thinner tom qab tempering, thaum 8-20mm iav ua 0.9-1.8mm thinner tom qab tempering. Qhov kev kawm tshwj xeeb nyob ntawm cov khoom siv, uas kuj yog vim li cas vim li cas tempered iav tsis tuaj yeem muaj daim iav tiav.

4.Cov iav tiaj tus siv hauv kev tsim kho tom qab lub cev tempering nyob rau hauv lub qhov cub tempering feem ntau undergoes deformation, thiab cov degree ntawm deformation yog txiav txim los ntawm cov cuab yeej thiab technical neeg ua hauj lwm txheej txheem. Rau qee qhov, nws cuam tshuam rau cov nyhuv zoo nkauj (tshwj tsis yog cov kev xav tau tshwj xeeb).

Test cov khoom rau tempered iav

1. Kev tshuaj xyuas qhov tshwm sim

Kev tshuaj xyuas qhov tshwm sim yog thawj txheej txheem ntawm kev tshuaj xyuas zoo rau cov iav tempered, uas feem ntau yog kev tshuaj xyuas cov iav saum npoo, nrog rau kev soj ntsuam qhov tsis xws luag xws li tawg, npuas, thiab khawb.

2. Khoovkuaj lub zog

dabtsi yog khoov lub zog yog ib qho tseem ceeb ntawm kev ua tau zoo ntawm tempered iav thiab ib qho tseem ceeb parameter rau kev ntsuam xyuas lub zog iav. Kev ntsuas lub zog khoov feem ntau yog siv plaub lub ntsiab lus dabtsi yog khoov txoj kev, uas siv lub zog rau lub khob phaj thiab saib xyuas nws qhov xwm txheej tawg kom tau txais cov nqi khoov lub zog.

3. Fragmentation hom nrhiav kom tau

Tempered iav qhia pom tseeb cov qauv tawg tom qab tawg, feem ntau muab faib ua radial fragmentation thiab fracture hom. Txoj kev tshawb nrhiav feem ntau yog siv cov kev soj ntsuam microscopic los ntsuas nws hom fragmentation.

4. Optical kev ua tau zoo ntawm tempered iav

Cov khoom siv kho qhov muag ntawm tempered iav yog qhov tseem ceeb rau nws cov ntawv thov. Qhov ntsuas qhov ua tau zoo ntawm cov iav tempered suav nrog kev xa tawm, diffuse reflectance coefficient, xim sib txawv, thiab lwm yam. Txoj kev kuaj pom feem ntau yog siv lub spectrophotometer lossis colorimetric meter rau kev kuaj.

5. Kev soj ntsuam zoo ntawm kev kho cua sov

Rau cov iav kub-kho tempered, qhov kub thiab lub sijhawm yog qhov tseem ceeb cuam tshuam rau nws qhov kev ua tau zoo. Yog li ntawd, rau qhov zoo ntawm kev kho cua sov, nws yog ib qho tsim nyog los xyuas qhov tsis xws li kev ntxhov siab saum npoo, khoov, thiab tawg ntawm cov iav.

Post lub sij hawm: Lub Xya hli ntuj-12-2024