Cov khoom siv ntoo xa mus rau cov khoom ua los ntawm cov ntoo ua raw khoom, sib sau ua ke nrog cov khoom siv kho vajtse, pleev xim rau thiab cov nplaum. Cov khoom ntoo muaj feem cuam tshuam nrog peb lub neej, xws li cov rooj zaum hauv chav nyob mus rau cov txaj hauv chav, me me raws li cov chopsticks peb feem ntau siv rau pluas noj. , nws qhov zoo thiab kev nyab xeeb muaj kev txhawj xeeb, thiab kev tshuaj xyuas thiab kev soj ntsuam ntawm cov khoom ntoo yog qhov tseem ceeb tshwj xeeb. Nyob rau hauv xyoo tas los no, cov khoom ntoo xa tawm los ntawm Tuam Tshoj, xws li wardrobes, rooj zaum, thiab sab hauv tsev thiab sab nraum zoov racks, kuj nrov heev nyob rau txawv teb chaws kev lag luam xws li Amazon lub e-commerce platform. Yog li yuav tshuaj xyuas cov khoom ntoo li cas? Dab tsi yog cov qauv thiab qhov tsis xws luag ntawm kev tshuaj xyuas cov khoom ntoo?

Kev tshuaj xyuas cov khoom ntoo thiab cov rooj tog ntoo

1.Txoj kev tshuaj xyuas dav dav rau cov khoom ntoo

2. Ntoo rooj tog soj ntsuam cov qauv thiab cov kev cai

3. Ntoo rooj tog sib dhos soj ntsuam cov qauv

4.Hardware soj ntsuam cov qauv

5.Carton soj ntsuam cov qauv

1. Kev soj ntsuam dav dav ntawm cov khoom ntoo

1. Tshawb xyuas cov qauv raws li tus neeg siv khoom kos npe. Yog tias tsis muaj cov qauv, nws tuaj yeem kuaj xyuas raws li cov duab meej thiab cov lus qhia ntawm cov neeg siv khoom.

2. Kev tshuaj xyuas kom muaj nuj nqis: Yog tias tus neeg siv khoom tsis muaj qhov tshwj xeeb, kev kuaj xyuas yuav tsum tau ua raws li tus qauv AQL.

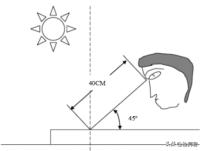

3. Kev soj ntsuam ib puag ncig: qhov ci ntawm lub teeb pom kev zoo yuav tsum yog 600-1000LUX, thiab lub teeb ci yuav tsum siab tshaj qhov ntsuas lub taub hau; yuav tsum tsis txhob xav txog ib puag ncig; Qhov kev ncua deb ntawm tib neeg lub qhov muag thiab cov khoom yuav tsum tau ntsuas ntawm 40cm, thiab lub kaum sab xis ntawm cov khoom yuav tsum ntsuas yuav tsum yog 40cm. 45 ° (daim duab).

Tshawb xyuas ib puag ncig

2. Cov qauv tshuaj xyuas thiab cov kev cai rau cov rooj tog ntoo

1. Kev tshuaj xyuas qhov muag

a. Lub pem hauv ntej nto yog tiaj, tsis muaj unevenness, thiab tsis muaj spikes. b. Lwm sab yog tiaj tus, cov xim tsis sib xws, tsis muaj xim sib txawv nrog rau pem hauv ntej, tsis muaj impurities, ua npuas ncauj luam ntawv. c. Cov xim sib txawv ntawm cov khoom ntawm tib yam khoom tsis tuaj yeem tshaj 5%, thiab tsis muaj qhov tshwm sim tsis zoo xws li hauv qab, tev, npuas, sagging, pob txuv, txiv kab ntxwv tev, pitting, ua npuas ncauj, impurities, thiab lwm yam d. Tsis muaj teeb meem xws li pob, cov npoo ntau dhau thiab cov ces kaum, cov tuab tuab, tsis muaj deformation. e. Yuav tsum tsis pub ntau tshaj 3 concave ntsiab lus ntawm 3 hli, thiab yuav tsum tsis txhob sib sau ua ke nyob rau hauv 10cm2; tsis pub ua pob.

2. Cov khoom loj, tuab, ntsuas qhov hnyav

Raws li cov khoom lag luam tshwj xeeb lossis cov qauv ntsuas los ntawm tus neeg siv khoom, ntsuas cov khoom lag luam ib qho loj, cov khoom tuab, cov khoom hnyav, lub thawv loj, lub thawv sab nraud, qhov hnyav tag nrho, yog tias tus neeg siv khoom tsis muab cov ntsiab lus kam rau ua, +/-3% kev kam rau siab yuav tsum tau siv.

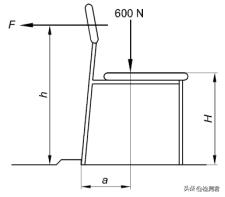

3. Kev kuaj Load Static

Ntau lub rooj tog yuav tsum tau kuaj cov khoom zoo li qub ua ntej xa khoom, xws li rooj, rooj zaum, rooj zaum reclining, racks, thiab lwm yam.

Txoj kev kuaj: Load ib qho hnyav ntawm cov khoom thauj khoom ntawm cov khoom kuaj, xws li lub rooj zaum lub rooj zaum, backrest, armrest, thiab lwm yam. Cov khoom yuav tsum tsis txhob tig, tipped, tawg, deformed, thiab lwm yam. Tom qab kev sim, nws yuav tsis cuam tshuam rau kev siv ua haujlwm.

4. Kev kuaj kev ruaj ntseg

Cov khoom thauj khoom ntawm cov rooj tog ntoo kuj yuav tsum tau kuaj xyuas kom ruaj khov thaum kuaj xyuas, xws li lub rooj zaum rooj zaum, backrests, thiab rooj zaum nraub qaum.

Txoj kev kuaj: Siv ib theem ntawm kev quab yuam los rub cov khoom thiab saib seb nws puas raug pov tseg. (Cov khoom sib txawv, qhov hnyav ntawm cov khoom siv, qhov kev ncua deb ntawm lub cable thiab lub zog ntawm lub cable sib txawv.)

Chair Stability Test

5. Co sim

Tom qab cov qauv sib sau ua ke, nws tau muab tso rau ntawm lub phaj kab rov tav, thiab lub hauv paus tsis tso cai rau viav vias.

6. Kev sim tshuaj tsw qab

Tag nrho cov khoom coj mus kuaj yuav tsum tsis muaj qhov tsis zoo los yog pungent tsw.

7. Barcode Scanning Test

Cov ntawv cim khoom thiab cov ntawv ntim sab nrauv tuaj yeem luam tawm los ntawm barcode scanners thiab cov txiaj ntsig scan raug raug.

8. Kev sim siab

Ib qho khoom hnyav thiab qhov loj me uas poob rau hauv cov rooj tog zaum ntawm qhov siab. Tom qab kev sim, lub hauv paus tsis pub muaj cov kab nrib pleb lossis deformation, uas yuav tsis cuam tshuam rau kev siv.

9. Kev ntsuas av noo

Siv tus qauv ntsuas dej los ntsuas cov dej noo ntawm cov khoom ntoo.

Kev sim txoj kev: Ntxig lub ntsuas dej ntub txog 6 hli sib sib zog nqus ntawm cov kab (yog tias nws yog cov khoom siv tsis sib cuag, tus tester yuav tsum nyob ze rau qhov ntsuas qhov chaw), thiab tom qab ntawd nyeem cov txiaj ntsig.

Yuav tsum muaj cov ntsiab lus ntawm cov ntoo noo noo: Thaum cov dej noo ntawm cov ntoo hloov pauv zoo heev, qhov tsis sib xws ntawm kev ntxhov siab tshwm sim hauv cov ntoo, thiab cov teeb meem loj xws li deformation, warpage, thiab cracking tshwm sim ntawm cov ntoo. Feem ntau, cov dej noo ntawm cov khoom ntoo hauv Jiangsu thiab Zhejiang cheeb tsam yog tswj raws li cov qauv hauv qab no: cov khoom siv ntoo npaj yog tswj ntawm 6 thiab 8, seem machining thiab cov khoom sib dhos yog tswj ntawm 8 thiab 10, cov ntsiab lus noo noo. ntawm peb lub plywood yog tswj ntawm 6 thiab 12, thiab ntau txheej Plywood, particleboard thiab nruab nrab ntom fiberboard yog tswj ntawm 6 thiab 10. Cov av noo ntawm cov khoom siv dav dav yuav tsum tau tswj qis dua 12

Wood Product Moisture Test

10. Kev kuaj kev thauj mus los (tsis yog rau cov khoom tawg yooj yim)

Kev xeem poob yog ua raws li ISTA 1A tus qauv. Raws li lub hauv paus ntsiab lus ntawm ib qho taw tes, peb sab thiab rau sab, cov khoom poob los ntawm ib qho siab rau 10 lub sij hawm, thiab cov khoom thiab ntim khoom yuav tsum tsis muaj kev tuag thiab teeb meem loj. Qhov kev ntsuam xyuas no yog siv los simulate lub caij nplooj zeeg dawb uas cov khoom yuav raug rau thaum tuav, thiab tshuaj xyuas lub peev xwm ntawm cov khoom los tiv thaiv kev sib tsoo.

3. Ntoo rooj tog sib dhos soj ntsuam cov qauv

Rau ntau cov rooj tog ntoo, cov khoom tau txais los ntawm cov neeg siv khoom kawg yog cov khoom siv ua tiav, uas yuav tsum tau teeb tsa los ntawm cov neeg siv khoom lawv tus kheej. Thaum kuaj xyuas cov khoom, cov neeg soj ntsuam yuav tsum paub qhov txawv ntawm cov khoom, cov khoom, cov khoom siv, cov txheej txheem, cov lus qhia, cov lus qhia thiab lwm yam khoom siv. Ua tiav cov khoom lag luam raws li cov kauj ruam hauv phau ntawv qhia, lub hom phiaj yog los xyuas seb cov khoom tsim thiab kev tsim khoom puas tsis txaus, thiab tseem tuaj yeem txheeb xyuas qhov kev ua haujlwm raug ntawm phau ntawv.

Kev sib dhos txoj cai:ntom, tiaj, ruaj, raug

Assembly General soj ntsuam tus qauv:

1. Txhua yam khoom siv yuav tsum muaj tseeb ua ntej sib dhos, suav nrog cov khoom siv, cov khoom siv, cov khoom siv, cov txheej txheem, cov lus qhia, cov lus qhia, thiab lwm yam.

2. Txhua qhov kev sib dhos yuav tsum tau nruj nreem txuas, ruaj khov thiab tsis muaj kab nrib pleb, lub dav hlau datum yog tiaj tus, muab tso rau hauv txoj kev, cov kab kab pheeb ces kaum sib npaug sib npaug, thiab sib npaug thiab sib haum xeeb;

3. Tag nrho cov nplaum sib dhos yuav tsum tau siv kom raug raws li qhov yuav tsum tau ua;

4. Cov khoom sib txuas ntawm txhua qhov sib dhos yuav tsum tau nplaum, thiab cov kua nplaum yuav tsum tau siv sib npaug thiab txaus. Tom qab sib sau ua ke, muaj cov kua nplaum ntws thoob plaws ib puag ncig;

5. Gluing method: Ua ntej gluing, tshuab plua plav tawm ntawm qhov chaw yuav tsum tau nplaum nrog rab phom cua. Cov kua nplaum nyob hauv huab cua yuav tsum tau muab faib rau hauv ib lub nplhaib, thiab tag nrho plaub phab ntsa yog glued; lub qhov ntev (niam tenon) kua nplaum yog siv rau qhov loj ntawm ob sab phab ntsa ntawm mortise thiab tenon; qhov chaw nrog cov txiv neej loj tenon lub xub pwg nyom yuav tsum tau coated nrog kua nplaum;

6. Cov kua nplaum uas nchuav yuav tsum tau muab so kom huv si hauv lub sijhawm, thiab yuav tsum tsis muaj cov kua nplaum seem uas yuav cuam tshuam rau daim duab.

Cov kev cai sib dhos:1. Cov qauv siv rau kab pheeb ces kaum ntev ntawm qhov kev sib tw sab nraud qhov yuam kev: ≥1000 ≤1.5 <1000 ≤1.0, piv txwv li: yog hais tias tus kab pheeb ces kaum ntawm lub txaj txaj thiab guardrail feem ntau nyob rau hauv 1000mm - 1400mm, kab pheeb ces kaum ntev yuam kev yuav tsum yog Tswj hauv qab 1.5mm. 2. Lub warpage ntawm daim (vaj huam sib luag), 700≤ kab pheeb ces kaum <1400≤1.5, kab pheeb ces kaum <700≤1.0, piv txwv li: muab lub guardrail los yog lub taub hau ntawm lub txaj rau ib tug kab rov tav siv dav hlau, feem ntau cov plaub fab yuav tsum nyob ruaj khov, yog tias muaj warpage ntawm ib lossis ob sab, qhov ntau ntawm qhov kev sib ntaus sib tua no yuav tsum tau tswj xyuas hauv qab 1.5 hli. 3. Ko taw ruaj khov mm ≤ 1.5; Piv txwv li: ib lub txaj sib dhos lossis rooj tog zaum yuav tsum muaj plaub taw kom sib npaug rau hauv av, tab sis yog tias muaj kev sib ntaus sib tua, qhov ntau yuav tsum tau tswj hauv qab 1.5 hli. 4. Sab sab perpendicularity mm Vaj Huam Sib Luag Diagonal ntev ≥1000 ≤1.5, <1000 ≤1.0, hais txog sag ntawm plaub fab ntawm cov rooj tog sib dhos thiab hauv av, thiab tus nqi tau los ntawm kev sib piv ntawm kab pheeb ces kaum.

Sab hauv nroj tsuag khib

4. Hardware soj ntsuam cov qauv

1. Cov lus qhia tshwj xeeb thiab qhov ntev ua tau raws li qhov yuav tsum tau ua, qhov tso cai sib txawv ntawm qhov ntev ntawm cov ntsia hlau yog ± 1 hli, cov ntsia hlau lub hau yuav tsum yog puag ncig, tsis muaj kab nrib pleb, cov hniav theem yog qhov tseeb, cov txiv neej thiab poj niam muaj kev sib tw dawb, yuav tsum muaj. tsis muaj qhov tseeb khoov tshwm sim, thiab tsis muaj khawb loj;

2. Tsis muaj xeb, tsis muaj khawb, tsis muaj deformation, qhov loj me, tsim nyog thiab ruaj khov, thiab xim zoo ib yam tag nrho;

3. Zoo compatibility nrog rau lwm yam accessories;

4. Cov tsos thiab cov duab raws li tus neeg yuav tsum tau muaj, thiab ua tau raws li qhov yuav tsum tau ua ntawm cov qauv, kos duab lossis cov qauv ua ntej yug menyuam;

5. Cov electroplating yog ruaj thiab tsis tuaj yeem poob.

6. Cov qauv tshuaj xyuas lub thawv

1. Lub ntsej muag zoo nkauj thiab huv si, qhov sib piv ntawm cov ntaub ntawv luam tawm rau lub thawv yog qhov sib npaug thiab tsim nyog, thiab cov ntawv sau tau meej;

2. Lub hardness thiab toughness ntawm lub thawv yuav tsum tau raws li qhov yuav tsum tau ntawm kev yuav khoom;

3. Cov pob qij txha ntawm cov thawv yuav tsum tau muab ntsia kom nruj thiab zoo zoo;

4. Qhov loj ntawm lub thawv yuav tsum ua tau raws li qhov xav tau;

5. Tsis txhob txais chromatic aberration, number case thiab lwm yam kuab paug;

6. Lub thawv thiab lub cim xa khoom yuav tsum raug thiab ua raws li cov ntaub ntawv kev lag luam;

7. Tsis txhob muab khawb, wrinkles thiab txheej;

8. Cov av noo yog tswj tsis pub dhau 12 degrees.

6. Kev piav qhia ntxaws txog qhov tsis xws ntawm cov khoom ntoo

1. Cov khoom tom qab ua cov ntoo tsis raug tso cai kom muaj qhov tsis xws luag hauv qab no:

a. Cov khoom ua los ntawm cov ntoo-raws li panels tsis muaj ntug-sealing kho. Tsuas yog qhov loj ntawm qhov chaw yuav tsum tau veneered los yog kaw nrog cov xim, tag nrho cov qhov chaw ntawm qhov chaw hla yuav tsum raug kaw. Txoj kev sib khi tuaj yeem pleev xim lossis lwm yam khoom siv. b. Muaj degumming, bubbling, splicing seams thiab ntshiab kua nplaum tom qab cov khoom siv cladding yog pasted; c. Muaj xoob, seams thiab puas ntawm cov pob qij txha ntawm qhov chaw, tenon-qhov pob qij txha, board qhov chaw thiab ntau yam kev txhawb nqa d. Cov tsos ntawm cov khoom yog tsis sib xws thiab asymmetrical; cov kab puag ncig thiab puag ncig ntawm cov khoom tsis sib xws thiab asymmetrical; e. Muaj cov qauv asymmetric thiab kab zoo tom qab carving thiab tig ntoo ua, hauv qab ntawm lub duav tsis sib xws, thiab muaj cov cim riam thiab cov kab nrib pleb; cov khoom Cov khoom sab nrauv tsis polished, sab hauv yog tsis polished, thiab muaj pom cov plaub hau thiab nti ntawm qhov ntxhib. 2. Cov teeb meem hauv qab no tsis raug tso cai rau ntawm cov khoom tom qab ua cov xim: a. Tag nrho cov khoom lossis ua tiav cov khoom muaj qhov sib txawv xim pom tseeb; txheej txheej ntawm cov khoom yog wrinkled, nplaum thiab to xim; b. Cov xim zaj duab xis txheej muaj qhov pom tseeb pos huab, dawb corrugations, dawb me ntsis, oily dawb, sagging, shrinkage qhov, bristles, hmoov tsub zuj zuj, lwm yam residues, khawb, bubbling thiab tev; c. Muaj kev nyuaj siab ntawm cov ntaub ntawv mos thiab tawv npog, Cov ntsiab lus, khawb, tawg, chipping thiab txiav npoo; d. Cov khoom tsis pleev xim rau ntawm cov khoom thiab cov khoom siv sab hauv tsis huv.

3. Tom qab cov khoom siv kho vajtse tau teeb tsa, tsis raug tso cai hauv qab no:

a. Muaj cov khoom uas ploj lawm hauv cov fittings, thiab muaj qhov nruab nrab qhov tsis muaj qhov nruab nrab; lub installation qhov chaw muaj cov ntsia hlau uas ploj lawm lossis los ntawm cov ntsia hlau; b. Cov khoom txav tau tsis hloov pauv; cov fittings tsis ruaj khov thiab muaj xoob;

Defect: Dent

Cov saum toj no yog cov txheej txheem tshuaj xyuas, cov qauv thiab cov teeb meem tseem ceeb ntawm cov khoom ntoo, Kuv vam tias yuav pab tau rau txhua tus. Yog tias koj muaj lus nug, koj tuaj yeem tiv tauj TTS rau kev sab laj.

Post lub sij hawm: Sep-01-2022