木製製品とは、木材を原材料として製造され、金具付属品を組み立て、塗装、接着された製品を指します。リビングのソファから部屋のベッド、食事の際に使うお箸のような小さなものまで、木製品は私たちの生活に密接に関わっています。 、その品質と安全性が懸念されており、木材製品の検査とテストは特に重要です。近年、ワードローブ、椅子、屋内外の植物ラックなど、中国から輸出される木製製品は、アマゾンの電子商取引プラットフォームなどの海外市場でも非常に人気があります。では、どうやって木製品を検査するのでしょうか?木材製品の検査基準とよくある欠陥は何ですか?

木製品・木製家具の検査

1.木製品の一般的な検査方法

2.木製家具の検査基準と要件

3.木製家具組立検査基準

4.ハードウェア検査基準

5.カートンの検査基準

1. 木製品の一般的な検査方法

1. お客様の署名に従ってサンプルを確認します。サンプルがない場合は、お客様から提供された鮮明な写真と製品説明書に従って確認できます。

2. 検査数量:顧客に特別な要求がない場合、サンプル検査は AQL 基準に従って実行されます。

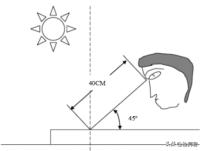

3.検査環境:周囲光の明るさは600-1000LUXである必要があり、光源は検査者の頭より高い必要があります。周囲に反射があってはなりません。人間の目と測定対象物との距離は40cm、測定対象物の角度は40cmに保つ必要があります。 45° (写真)。

環境を確認してください

2. 木製家具の検査基準と要求事項

1. 目視検査

a.表面は凹凸がなく、スパイクのない平らな面です。 b.他の面は平らで、色は均一で、前面との色の違いがなく、不純物がなく、発泡印刷です。 c.同じタイプの製品のバッチ間の色の違いは 5% を超えてはならず、底の露出、剥離、気泡、たるみ、ニキビ、オレンジの皮、穴あき、泡跡、不純物などの有害な現象はありません。凹凸、過剰なエッジや角などの欠陥がなく、厚さが均一で、変形がありません。 e. 3mm の凹みが 3 個以内であり、10cm2 以内に集まっていないこと。凹凸は許されません。

2. 製品のサイズ、厚さ、重量のテスト

顧客が提供した製品仕様またはサンプルテストに従って、単一製品のサイズ、製品の厚さ、製品の重量、外箱のサイズ、外箱の総重量を測定します。顧客が詳細な公差要件を提供しない場合、+/-3%公差を使用する必要があります。

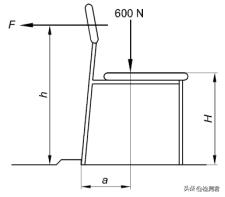

3. 静荷重試験

テーブル、椅子、リクライニングチェア、ラックなど、多くの家具は出荷前に静荷重テストを行う必要があります。

試験方法:試験製品の椅子の座面、背もたれ、肘掛けなどの荷重がかかる部分に一定の重量を載せ、転倒、転倒、亀裂、変形などが生じないこと。機能的な使用には影響しません。

4. 安定性試験

椅子の座面、背もたれ、ソファの背もたれなど、木製家具の耐荷重部分も検査中に安定性をテストする必要があります。

試験方法:製品を一定の力で引っ張り、ダンピングするかどうかを観察します。 (製品により、使用物の重量、ケーブルの距離、ケーブルの強度が異なります。)

椅子の安定性テスト

5. 振とうテスト

サンプルを組み立てた後、サンプルを水平のプレート上に置き、ベースが振れないようにします。

6.臭気試験

サンプリングされたすべての製品には、不快な臭いや刺激臭があってはなりません。

7. バーコードスキャンテスト

製品ラベルと外装ラベルをバーコードスキャナーでスキャンでき、スキャン結果は正確です。

8. 衝撃試験

指定された高さで家具の座面に自由に落下する、一定の重量とサイズの荷重。テスト後、ベースに亀裂や変形が認められませんが、使用には影響しません。

9. 湿度試験

標準的な水分計を使用して、木製部分の含水率をチェックします。

試験方法:ウェットテスターを線に沿って深さ約6mm挿入し(非接触型の場合は試験面に近づけてください)、結果を読み取ります。

木材の含水率に対する要求:木材の含水率が大きく変化すると、木材内部に不均一な内部応力が発生し、木材の外観に変形、反り、割れなどの大きな欠陥が発生します。一般に、江蘇省と浙江省地域の無垢材の含水率は次の基準に従って管理されています。無垢材準備セクションは 6 ~ 8、機械加工セクションと組立セクションは 8 ~ 10、含水率は 8 から 10 の間に管理されています。 3枚合板の湿度は6~12、多層合板、パーティクルボード、中密度繊維板は6~10に管理されています。一般的な製品の湿度は12以下に管理されています。

木製品の水分試験

10. 輸送落下試験(壊れやすいものは対象外)

落下試験は ISTA 1A 規格に従って実施されます。 1点、3面、6面の原則に従って、製品を一定の高さから10回落下させ、製品および梱包に致命的かつ重大な問題が発生しない必要があります。このテストは主に、製品の取り扱い中に受ける可能性のある自由落下をシミュレートし、偶発的な衝撃に耐える製品の能力を検査するために使用されます。

3. 木製家具組立検査基準

多くの木製家具の場合、最終消費者に受け取られる製品は半完成品であり、消費者自身が設置する必要があります。商品を検査する際、検査官は材料、コンポーネント、ハードウェア、プロセス、仕様、説明書、その他の関連付属品を区別する必要があります。取扱説明書の手順に従って製品を完全に取り付けてください。製品の構造や製造精度に不備がないかを確認するとともに、取扱説明書が正しく動作することを確認することが目的です。

組み立て原理:緻密、平坦、しっかり、正確

組立一般検査基準:

1. 材料、コンポーネント、ハードウェア、プロセス、仕様、説明書などを含むすべての付属品は組み立て前に正確である必要があり、正しく一致している必要があります。

2. すべての組み立て接合部はしっかりと接続され、しっかりしていて亀裂がなく、基準面が平らで正しい方向に配置され、関連する対角線が等しく、対称的かつ調和している必要があります。

3. 組み立てられた接着剤はすべて、品質要件に従って正しく使用する必要があります。

4. すべての組立部品の接続部分は接着する必要があり、接着剤は均一かつ適切に塗布する必要があります。組み立て後、接着剤が周囲に溢れています。

5.接着方法:接着する前に、接着する部分のゴミをエアガンで吹き飛ばしてください。空気中の接着剤はリング状に分散され、4 つの壁すべてが接着されます。長穴 (母ほぞ) の接着剤は、ほぞ穴とほぞの 2 つの側壁の大きい方に塗布されます。大きなオスのほぞ肩を持つ部品は接着剤でコーティングする必要があります。

6. こぼれた接着剤は適時に拭き取り、塗装に影響を与える接着剤が残らないようにしてください。

組み立て要件:1. 反対側の長さの誤差の対角線の長さの基準: ≥1000 ≤1.5 <1000 ≤1.0、たとえば: ベビーベッドのヘッドボードとガードレールの対角線が通常 1000mm ~ 1400mm 以内の場合、対角線長さの誤差は次のようになります。 1.5mm以下に管理されています。 2. ピース (パネル) の反り、700 ≤ 対角長さ < 1400 ≤ 1.5、対角長さ < 700 ≤ 1.0 例: ガードレールまたはベッドの頭部を水平基準面に置き、通常は四隅が安定するように、片側または両側に反りがある場合、この反りの範囲は 1.5 mm 未満に制御する必要があります。 3. 足の安定性 mm ≤ 1.5;たとえば、組み立てられたベッドや家具は地面と平行になるために 4 フィートが必要ですが、反りがある場合は、その範囲を 1.5 mm 未満に制御する必要があります。 4. 隣接辺直角度 mm パネル対角長 ≧1000≦1.5、<1000≦1.0とは、組立家具の四隅と地面とのたわみとその対角線を比較して求めた値をいいます。

屋内植物ラック

4. Hハードウェア検査基準

1.仕様と寸法は要件を満たしており、ネジの長さの許容偏差は±1mmで、ネイルキャップは丸く、亀裂がなく、歯のレベルは明確で、オスとメスは自由に一致しており、明らかな曲がり現象や重大な傷はありません。

2.錆びず、傷がなく、変形がなく、サイズが一貫しており、構造が合理的でしっかりしており、全体として色が一貫しています。

3. 他の関連アクセサリとの良好な互換性。

4. 外観と形状は顧客の要件を満たし、テンプレート、図面、または出生前サンプルの要件を満たします。

5.電気メッキはしっかりしていて、落ちることはありません。

6. カートンの検査基準

1. 外観はきちんとしていてきれいで、カートンに対する印刷物の比率は均整がとれて合理的であり、手書きは鮮明です。

2. カートンの硬度と靭性は注文書の要件を満たしている必要があります。

3. カートンの接合部はしっかりときれいに釘で打たれている必要があります。

4. カートンのサイズは注文要件を満たす必要があります。

5.色収差、インク、その他の汚染を受け入れないでください。

6. カートンと出荷マークは正確であり、ビジネス情報と一致している必要があります。

7. 傷、しわ、層を受け入れないでください。

8.湿度は12度以内に管理されています。

6. 木製品の欠陥についての詳しい説明

1. 木材加工後の製品には、次のような欠陥があることは認められません。

a.木質パネルで作られた部品にはエッジシール処理が施されていません。ベニヤで覆われたり、ペイントで閉じられたりする大きな表面を除いて、断面のすべての露出部分を閉じる必要があります。封止方法は塗装やその他の材質でも可能です。 b.クラッディング材を貼り付けた後は、脱ガム、泡立て、継ぎ目と透明な接着剤が必要です。 c.部品の接合部、ほぞ穴接合部、板部品、各種サポート等に緩み、継ぎ目、破断がある。 d.製品の外観は不均一で非対称です。製品の丸い線と丸い角は不均一で非対称です。 e.木材加工後に彫刻や旋削加工を施した後の模様や線の形状が非対称であったり、シャベルの底に凹凸があったり、ナイフの跡やひび割れがあったりと、商品は外面未研磨、内面未研磨、ザラザラした部分には鋸毛や傷がございます。 2. 塗装加工後の製品に次のような欠陥がある場合は認められません。製品全体または製品の完全なセットには明らかな色の違いがあります。製品の表面コーティングにしわがあり、ベタベタしており、塗料が漏れています。 b.塗膜塗装 明らかな曇り、白波、白斑、油白、タレ、ヒケ穴、毛羽立ち、粉溜まり、雑多な残留物、傷、気泡、剥がれ等が見られます。 c.柔らかいおよび硬い被覆材の表面にくぼみ、点、傷、亀裂、欠け、刃先があります。 d.製品の未塗装部分や製品内部はきれいではありません。

3. ハードウェアアクセサリを取り付けた後は、次の欠陥は認められません。

a.金具に欠品があり、取り付け穴があり取り付け部品がありません。取り付け部分に釘が欠けている、または釘が貫通している。 b.可動部分は柔軟性がありません。金具がしっかりと取り付けられておらず、緩みがある。

欠陥: へこみ

以上、木製品の検査方法・基準・主な欠点についてご紹介しましたので、皆様のお役に立てれば幸いです。ご質問がある場合は、TTS にお問い合わせください。

投稿日時: 2022 年 9 月 1 日