What is clothing flaw

Clothing rips refer to the phenomenon that clothing is stretched by external forces during use, causing the fabric yarns to slip in the warp or weft direction at the seams, causing the seams to come apart. The appearance of cracks will not only affect the appearance of the clothing, but also reduce the performance of the clothing.

The main causes of discrepancies

fabric quality

1. Yarn twist: In order to highlight the main effect of the granular surface of the fabric, some fabrics adopt a process design in which the warp yarns are untwisted and the weft yarns are strongly twisted, so that the friction coefficient between the warp and weft yarns is reduced, the yarns are smooth, and the cohesion force is poor. It is easy to cause warp and weft yarns to slip in the weft direction.

2. Yarn count: If the difference in warp and weft yarn counts is too large, the difference in joint surfaces between the two sides of the interweaving point will increase, the friction area will decrease, and thicker yarns will easily slip on thinner yarns.

3. Fabric structure: Under the same conditions, twill and satin weave are more prone to cracks than plain weave.

4. Fabric tightness: Due to the small fabric tightness of light and loose fabrics, the warp and weft yarns are loosely arranged. When external forces are applied, the yarns are easy to shift, crack or slip. The main factors affecting sewing quality and cracks are stitch density, overlock seams, needle threads and seam allowances. Appropriate stitch density should be selected for different fabrics. The main reason for seam slippage is that the seam allowance is too small. Because the seam allowance is small or there are few overlocks, the loose edge yarn can easily slip away from the seam.

The magnitude of the force at the joint

For example, generally, the sleeve seams, shoulder seams, trousers back cover and other parts are more likely to have cracks, because these parts are relatively stressed and cause the seams to slip.

Garment sewing quality

If the stitch density is high, there are many overlocks, and the seam allowance is large, and sewing in a zigzag manner, the seams will be less prone to cracks, and vice versa.

How to improve the degree of rips in clothing?

To solve the problem of clothing rips and enhance durability, the following influencing factors should be considered.

1. Improve fabric performance, fully consider the impact of process parameters on cracks when designing fabrics, configure them reasonably, and try to increase the friction coefficient between warp and weft yarns to reduce slippage while maintaining the fabric style;

2. The clothing production process should be different according to the material to improve the firmness of the seams and avoid slipping;

3. Consumers should choose appropriate styles according to different fabrics. For light and thin fabrics or easy-to-slip fabrics, they should be loose to reduce the stretching force at the seams.

Are seam performance and flaw degree in clothing testing the same thing?

What is seam performance?

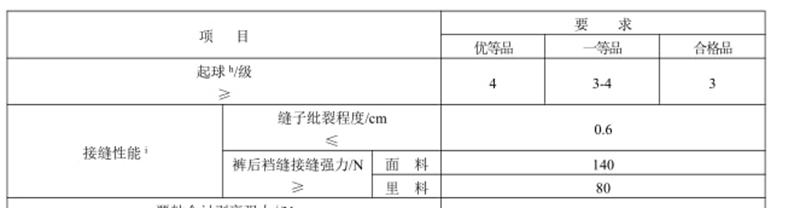

Seam performance is a general term for various properties of seams. According to GB/T 21294-2014 “Test Methods for Physical and Chemical Properties of Clothing“, it includes the degree of cracks, seam strength, and crotch seam seam strength. The degree of cracking is assessed by the degree of yarn detachment after the seam is stretched under a certain load, while the seam performance is assessed by the various properties of the seam. It can be seen that the seam performance includes the cracking performance. Relatively speaking, seam performance is a more comprehensive assessment of samples. At present, the newly revised or released woven clothing product standards will basically use the indicator of “seam performance” instead of “level of flaw”.

For example:

FZ/T 81007-2022 “Single and Sandwich Clothing” stipulates that the requirements for seam performance are “cracks ≤ 0.6cm, fabric breakage, slippage, and sewing thread breakage shall not occur during the flaw test process.” The test before the comma is the flaw degree, and what follows the comma is the requirements for other properties of the seam. It can be seen that the new standard’s assessment of seams is not limited to the risk of yarn slippage, but also incorporates the risk of seam damage, which is more comprehensive and more in line with the actual situation than the previous assessment of the degree of cracks.

Post time: Oct-13-2023