Part 1. What is AQL?

AQL (Acceptable Quality Level) is the basis of the Adjusted Sampling System, and is the upper limit of the process average of the continuous submission of inspection lots that can be accepted by the supplier and the demander. The in-process average is the average quality of a series of consecutively submitted inspection lots, expressed as a “Lot Rejection Rate” or “Defects Per Hundred Units”. The relationship between AQL and sampling size lies in one inspection level (three general inspection levels I, II, and III, and four special inspection levels S-1, S-2, S-3, and S-4) and the degree of leniency (severities).

For example, a product batch N=4000, the agreed AQL=1.5%, and the selected inspection level is II, the steps to determine the adjusted one-time sampling inspection plan are:

1) According to the GB2828-81 table, the sample content code is L;

2) Determine the “normal sampling plan”: the number of qualified judgments corresponding to L and AQL=1.5% is 7, the number of unqualified judgments is 8, and the sample content is n=200. Its meaning is: 200 samples are taken out of 4,000 products and sent for inspection. If the number of unqualified products in these 200 is less than or equal to 7, the whole batch of products is qualified; if it is greater than or equal to 8, the whole batch is unqualified;

3) In the same way, determine the sampling plan of “tightening”, “relaxing” and “extremely relaxing”;

4) Combining the four sampling plans into one place and using the dynamic conversion rule (in the sap system, the term dynamic modification rule) constitutes an “adjusted one-time sampling plan”;

5) The above examples follow the GB2828 standard, which corresponds to ISO2859 (counting). There is an ISO version of sample scheme in version 4.5B of SAP system.

6) You can refer to a dynamic modification rule “s01″ in the SAP standard system 4.5B, which is relatively clear.

Part 2. Practical AQL knowledge

1. Overview of AQL inspection

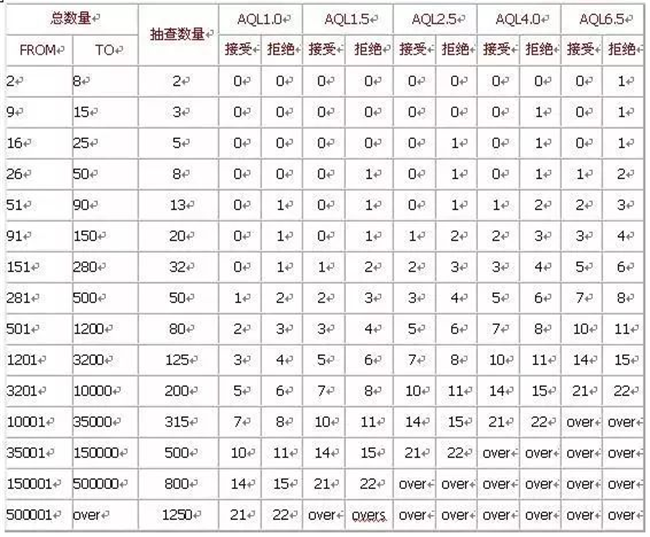

AQL: is the abbreviation of English average quality level, that is, the average quality level. It is a parameter of inspection, not a standard. During the inspection, the quantity of sampling and the quantity of qualified and unqualified products are determined according to: batch range, inspection level, and AQL value. The garment quality inspection adopts a one-time sampling plan, the qualified quality level (AQL) of the batch of garments is 2.5, the inspection level is the general inspection level, and the inspection strictness is normal inspection. The sampling plan is shown in the table:

The sampling plan for normal inspection is: (AQL-2.5 and AQL-4.0)

2. Items of clothing inspection

1. Dimensions and appearance inspection: — Dimensions and appearance table

1) Key size points — Collar length (plain weave), collar width, collar circumference (knitted), collar spread (knitted) bust, sleeve opening (long sleeve), sleeve length (to sleeve edge), back length (plain weave) center measurement (knit) / shoulder top measurement pants, waist, lower hip, front wave, back wave, zipper opening, hem opening, inner circumference / back mid-length other (single piece/set), garment when vertical, pants size.

2) Non-critical dimension points — non-critical dimension points, such as minimum must-have, shoulder height, bust, sleeves, collar width, sleeves, front and rear waves, waist inner circumference, lower hip circumference, flat pocket, opening.

2. Defect inspection: The appearance, shape, dressing and found defects of all clothes are classified separately.

The content of the defect is attached.

Three. Grading

AQL is the largest number of defect points in 100 pieces of clothing. It is based on the number of qualified judgments Ac (pieces) after sampling inspection, and the average processing level of this clothing batch (pieces) is considered satisfactory. When the number of unqualified judgments Re (pieces) is reached, the average processing level of this garment batch (pieces) is considered to be an unacceptable level. The following are the standard scoring criteria for scoring during the inspection process:

1. General defects — Starting from the organizational specifications and quality standards of the order, it does not reach the performance of the product, which affects the appearance and interior of the garment. Non-critical dimensional points and general defects can eliminate the influence of defects on the appearance and inner nature of garments during rework. If the garment is reworked on the basis of this defect, it must be 100% re-inspected before shipment, and the inspector can limit the specific specifications, colors, sizes, etc. of the inspection. Three general defects are converted into one serious defect.

2. Serious defects — affect the appearance and shape of the garment. When a consumer buys and sees such a defect, they will not buy the garment again, or if the defect will cause the garment to be uncomfortable the first time or after washing, the consumer will return it. Such as damage, stains, color bars, holes, critical dimension points, etc. are all serious defects. If a serious defect is found, the second garment is judged to be unacceptable or unacceptable.

Four. Three-step inspection method (pre-production inspection, start production line inspection, final product inspection)

1. Pre-production inspection

This is a prenatal inspection, to check specific specifications or the company’s general requirements, the focus of this inspection is: dressing, packaging, trademarks, printed patterns, color standards, re-checking the specification sheet and all relevant information, clear before cutting its content.

2. Inspection during production

After confirming the first or first batch of finished products, check the finished products by sampling, and check the contents: size, color, design, material, organizational structure, handwork, finished product’s trademark, price tag, and packaging. If there is any problem, the information should be fed back to Cut, sew, have them recheck and correct.

3. Finished product inspection

Generally, at least 80% of the production has been completed and packaged for shipment. The samples to be inspected must be randomly selected from the finished garments. If the inspection fails, the entire batch must be inspected 100%, and the non-conforming products will be reworked by the factory. The final inspection report determines: 1. The box wheat is accurate, 2. The gross weight and size of the carton, 3. The net weight of the goods, 4. The final size and color matching.

Five. Needle detection

Due to poor management in the production process, there are often broken needles (including sewing needles, pins, etc.) in quilted products such as clothing. In the 1980s, consumer injuries caused by broken needles in clothing occurred frequently, which prompted the government to promulgate consumer rights protection regulations in the form of legislation to strengthen the control of broken needles. According to the regulations, if there are broken needles in the products produced and distributed, the producers and sellers will be severely punished, and if they cause harm to consumers, they will also be compensated. In order to avoid economic losses caused by broken needles, garment importers not only require manufacturers to inspect needles before they leave the factory, but also set up special inspection factories for needle inspection. For products that have passed the needle inspection, hang or affix the needle inspection mark.

Six. Clothing testing

1. Need to show that the cloth has been tested

2. The clothes test is carried out as follows

1) The inspector randomly selects ready-made garments from the bulk for testing

2) Do the test with the same quality sample set of clothes as the bulk

3) Tested by the factory itself using the standard garment washing test method

The final experiment must be personally inspected by the inspector, and if there are facilities that violate the regulations, a detailed observation report should be written.

Attachment: list of defects

1. Defects related to the appearance of garments

■ The color of the cloth exceeds the specified range, or exceeds the allowable range on the control card

■ Films/lines/visible accessories with obvious color difference

■ Obvious surface spherical 204. Printing defects

■ Lack of color

■ The color is not fully covered

■ Misspelling 1/16″* The pattern direction does not meet the specification 205. The strips are misaligned, and when the organizational structure requires the strips to be aligned, the wrong 1/4

■ Misalignment more than 1/4″ (at the placket or trousers open)

■ More than 1/8″ misalignment, placket or center piece

■ Misplaced by more than 1/8″, bag and pocket flaps 206. Cloth bowed or slanted, sides not equal by more than 1/2″” dressing,

■ Broken yarn, broken ends (yarn), holes caused by less needles

■ Permanent horizontal lines, vertical lines on the fabric, including stitches

■ Oil, dirt, visible within the sleeve length

■ For plaid cloth, the appearance and shrinkage are affected by the cutting relationship (flat lines are expressed in the warp and weft directions)

■ There are obvious rungs and strips, which affect the appearance in a large range

■ Exposed lining color

■ Wrong warp, wrong weft (woven) dressings, spare parts

■ The use or substitution of unapproved dressings that affect the appearance of the fabric, such as paper backing, etc.

■ Any special dressing spare parts are missing or damaged, so that they cannot be used according to the original requirements, such as buttons cannot be buttoned, zippers cannot be closed, and fusible things are not indicated on the instruction label of each piece of clothing

■ Any organizational structure adversely affects the appearance of clothing

■ Sleeve reverse and twist

2. Button

■ Button missing nails

■ broken, damaged, defective, on the contrary

■ Does not meet specifications

■ Buttons are too big or too small

■ Buttonhole burrs, (caused by the knife not being fast enough)

■ Misaligned or incorrect position, resulting in deformation

■ Lines are not aligned with the color, or the color alignment is not good

■ The density of the thread does not match the characteristics of the cloth

3. Paper lining

■ Fusible paper liner must match each garment, not foam, wrinkle

■ For clothes with shoulder pads, do not extend the shoulder pads out of the hem

4. Zipper

■ Any functional incompetence

■ The cloth on both sides does not match the color of the teeth

■ The zipper car is too tight or too loose, resulting in uneven zipper bulges and pockets

■ After the zipper is opened, the clothes do not look good

■ zipper side tape is not straight

■ The pocket zipper is not straight enough to bulge the upper half of the pocket

■ Aluminum zipper cannot be used

■ The size and length of the zipper do not match the length of the place where the clothes are used, or do not meet the specified requirements

5. Corns or hooks

■ Missing nails or nailing in the wrong place

■ Hooks and corns are out of center, and when fastened, the fastening points are not straight

■ New metal accessories, hooks, eyelets, stickers, rivets, iron buttons, etc. are not rust-proof or easy to clean

■ Inappropriate specifications and inaccurate positioning

6. Belt

■ Color does not meet requirements

■ Bandwidth exceeds 1/4″ of specification

■ The number of buttonholes is not as required

■ The top stitching of the belt is uneven or wrinkled

■ The buckle pin is missing or the buckle is not strong

■ Buckle and belt size do not match

■ The length of the belt must correspond to the clothing

■ For clothes with brackets, the inner brackets must not be exposed, (hem)

■ All metal accessories (eyes, hooks, leads, buckles) must be rust-proof, washable and dry

7. Wash the label and write the trademark

■ The washing label is not logically written, or the precautions are unclear, and the written content does not meet the requirements of all customers

■ Inaccurate fiber composition origin and RN number

■ The location of the trademark does not meet the requirements

■ Logo must be fully visible, position error +-1/4″ 0.5 line

8. Hooks, rivets, button hooks, buttons have defects, damage, inaccurate positions, and look unsightly

9. Machine line

■ Needle per inch +2/-1 exceeds requirements, or does not meet specifications

■ The shape and pattern of the stitches do not meet the requirements, for example, the haoke is not strong enough

■ Back stitch at least 2-3 stitches when the thread is reversed

■ Repair stitches, repeat not less than 1/2″ on both sides, chain stitches must be wrapped with overlock stitches or chain stitches that can be included

■ Defective stitches

■ Chain stitch, overcast, overlock stitch, broken, less, skip stitch

■ Lock stitch, no skipped stitches and broken threads are allowed in critical parts in every 6″ seam

■ Buttonhole skip stitch, cut, loose stitch, not fully secure, wrong center position, loose, not all X stitches as required

■ Barrier length, position, width, density of stitches do not meet requirements or are omitted

■ Twisting and wrinkling of dark threads due to tightness

■ Irregular or uneven stitches, poor seam control

■ Out of control stitches

■ Special thread size affects the fastness of clothes

■ When the sewing thread is too tight, it will cause the thread and cloth to break when it is in a normal state. To properly control the length of the yarn, the sewing thread must be extended by 30%-35%

■ The original edge is outside the stitch

■ Stitches are not firmly open

■ Severely twisted, when the stitches on both sides are stitched together, they are not placed straight enough so that the trousers are not flat, and the trousers are twisted

■ Thread length is longer than 1/2″

■ 0.5 stitches visible in garment under the crochet or 1/2″ above the hem:

■ Broken wire, outside 1/4″

■ Top stitch, single and double needles not head-to-toe, for one stitch 0.5 stitches, Haoke

■ All car lines should be straight to the clothes, not twisted and skewed, there are at most three places that are not straight

■ The pleated area of sewing is more than 1/4, the internal performance is multi-needle fixed, and the external car is out

10. Finished product packaging

■ No ironing, folding, hanging, plastic bags, bags and matching do not meet the requirements

■ Bad ironing includes chromatic aberration, aurora, discoloration, and any other defects

■ Size stickers, price tags, hanger sizes are not available, not in place, or out of specification

■ Any packaging does not meet the requirements (hangers, bags, cartons, box tags)

■ Improper or illogical printing, including price tags, hanger size labels, packaging boards

■ The content of the carton does not conform to the main defect list of garments

11、Accessories

Accessories such as color, specification, and appearance do not meet the requirements. Such as shoulder straps, paper linings, elastics, zippers, buttons, etc.

12、Structure

■ Front hem not flush 1/4″

■ The lining is exposed at the top

■ The attachments and film connections are not straight and more than 1/4″. Cases, arm cages

■ The patch does not correspond to more than 1/4″ in length

■ The shape of the sticker is not good, causing it to bulge on both sides after sticking it

■ Improper placement of stickers

■ The waist is irregular or the width of the corresponding part exceeds 1/4″

■ Elastic webbing is not evenly distributed

■ Left and right stitches must not exceed 1/4″ inside and outside Shorts, tops, pants

■ Ribbed collar, keve not more than 3/16″ wide

■ Long sleeves, hem, and high-neck ribbing, not more than 1/4″ wide

■ The position of the placket does not exceed 1/4″. When the zipper is closed, the cloth is not covered, or the zipper is opened and closed not straight, and the sleeves and cuffs are defective

■ Exposed stitches on sleeves

■ Misaligned by more than 1/4″ when attached under the cuff

■ Coffey is not straight

■ Kraft is out of position by more than 1/4″ when putting on the sleeve

■ Inner jacket, left tube to right tube, left bar to right bar difference 1/8″ bar less than 1/2″ special width 1/4″ bar,

■ The difference between the length of the left and right sleeves is over 1/2″

■ Excessive bulging, wrinkling, and twisting of the collar (top of the collar)

■ The collar tips are not uniform, or are noticeably out of shape

■ Over 1/8″ on both sides of the collar

■ The collar dressing is noticeably uneven, too tight or too loose

■ The stitching of the collar is uneven from top to bottom, and the inner collar is exposed

■ After the collar, the center point is wrong

■ The rear center collar does not cover the collar

■ Overcome unevenness, distortion, or bad looks

■ The beard fly is unbalanced, more than 1/4″ when the shoulder stitches are compared to the front pockets

■ Pocket level is unbalanced, more than 1/4″ off center

■ Obvious bending, the specification and weight of the pocket cloth do not meet the regulations, and the pocket size is out of proportion

■ The corners of the flap exceed the pocket by 1/8″

■ The shape is different, or the bag is obviously skewed horizontally, left and right

■ Obvious slant, 1/8″ off centerline

■ Buckle position over 1/4″

■ With shape, wrong color

■ Line color does not correspond to it

■ Wrinkled or uneven

■ More than 1/4″

■ Cuff hem of varying size, skew and poor appearance

■ Hem hem more than 1/2″ left and right or front and rear

■ Hems, elastics, ties at the sides, collars, sleeves, leg openings, and waist openings are not aligned by more than 1/8″

Post time: Aug-08-2022