Crane inspection belongs to the industrial inspection of large-scale construction machinery and equipment. During on-site inspection of industrial products, the inspection of mechanical products such as cranes requires that they pass the complete machine trial operation test. If there are special requirements, in addition to functions, production capacity must also be calculated to meet customer needs.

01 Crane inspection sampling method

For mass-produced cranes, the number of crane prototypes used for inspection and testing shall be mutually agreed between the manufacturer/supplier and the purchaser.

02 Crane inspection instruments and meters

- When inspecting and testing cranes, instruments with appropriate accuracy and measuring range should be selected;

-The required instruments and meters should pass the verification/calibration and be within the verification/calibration validity period.

03 Crane inspection standards and methods

Crane inspection classification includes 4 types of inspections: visual inspection; parameter measurement and performance verification; load test; noise test (if necessary).

1. Crane inspection and visual inspection

Visual inspection - Check that all important components comply with the specifications and/or condition according to the crane type:

- Electrical, hydraulic and pneumatic equipment; - Crane mechanisms, important metal structures and their connections; - Ladders, passages, cabs, platforms; control devices, lighting and signals, wind speed measuring devices; all safety protection devices; - Reels , brakes, reducers and their supporting structures and fasteners; wire ropes or other rigging and their connections and fasteners; - pulley blocks and their pins and fasteners connections: - hooks or other lifting cranes Tools and their connectors and fasteners; - safety signs and hazard icons; - information signs.

Visual inspection - inspection of acceptance documents and relevant technical documents:

-The basic technical parameters and various ratings of the crane must list the working conditions and main parameters consistent with the intended use of the crane. - Basic information and technical performance of the crane and its components as well as acceptance documents. - Information from both the crane seller and manufacturer, basic data of the equipment, environment and working site characteristics and other basic information - Relevant technical performance must be given in detail about the crane and its components in terms of overall dimensions, work layout, crane quality and other relevant parameters technical performance. - Records of technical data of the crane and its components in actual operating conditions, which must be present and confirmed by a competent person during the final test prior to acceptance.

2. Parameter measurement and performance verification

Parameter measurement and performance verification of a crane should be based on the type of crane. The measurement or verification is not limited to the parameters and performance specified below:

-Crane mass (if necessary):

-The distance from the rotation axis to the overturning line;

-Lifting height/descending depth:

-Extreme position of hook;

-Track tolerance, span, gauge, base distance;

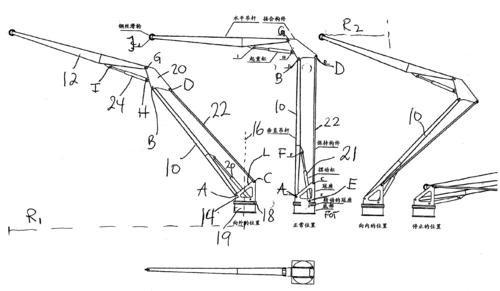

-Maximum and minimum amplitude;

-Effective reach of the cantilever;

-Lifting/lowering speed:

-The running speed of large vehicles and small vehicles;

-Swing speed;

-Amplitude (pitch) time;

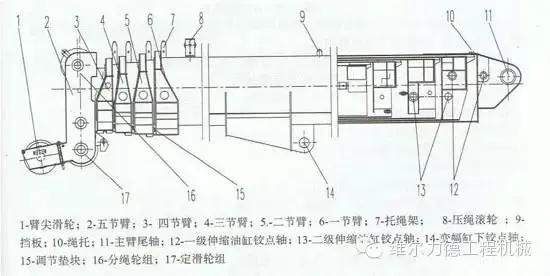

-Boom expansion and contraction time;

-safe distance;

-Duty cycle time (if necessary)

-Function of limiters, indicators and safety devices;

- the performance of the drive, such as the current of the motor under test load conditions;

-Important coal seam quality (when necessary).

Post time: Jun-18-2024