01First, let’s talk about the production cycle

The production cycle here is defined as the time period from pre-production samples to CRD (Cargo Ready Date) after the order is placed. According to the different nature of the order, it is divided into:

1. 1st Time Buy or Replenished. 2. Supplier Export Order (Direct Import) or Supplier Domestic Order (Domestic)

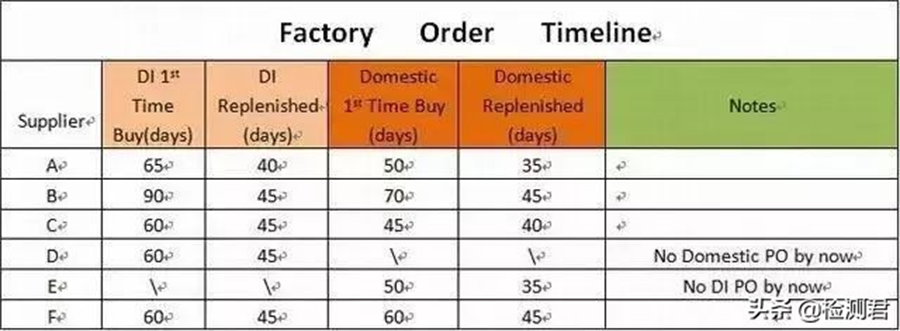

Different suppliers have different capacities, so it can be very confusing if you don’t do data processing. After a simple table statistic, the production cycle of several suppliers is roughly as follows:

Note: The supplier’s export order generally involves third-party testing and inspection, and usually the supplier’s domestic order requirements are relatively simplified, so the production cycle of DI orders will be longer than that of Domestic orders. It is not difficult to understand that the above is a simple Graphical table of the production cycle of each supplier.

02Let’s look at the order rules

Before talking about the rules of placing orders, in order to facilitate understanding and digestion, order items are divided into two types:

1. Promotion Order (promotional order, one-time order) 2. Inline Order (there will be long-term order items that will be reversed for a period of at least one year)

The promotional order is obviously over after the 1st Time Buy process, and the Inline Order will include restocking in addition to the first time buy. Just received an email from the foreign headquarters today, all orders for the Spring 2019 Domestic (Inline) project have been confirmed, so Xiaocan will take the 2019 Spring project as an example. Generally, orders for spring projects will be placed to suppliers before the end of September. Why? This is going back to the first point, the production cycle of the factory and the relatively fixed shipping schedule. We will follow the push first and place an order on September 20. According to demostic’s 1st Time Buy production timeline, (order date + production cycle), the fastest shipping time is November 5, and the latest shipping time is 11. 29th. It seems still early, there is still more than a month before 2019, but it is not. After the goods are dispatched, we also need to calculate the time for the goods to float at sea. Except for some Southeast Asia and the western regions of the United States that have a short transportation time (about 20 days), the shipping time for the goods to other countries and regions is about 40 days, plus customs declaration. The customs clearance time, the entire shipping time is about 55 days. In this way, the time for the goods to arrive at the customer’s warehouse has reached January 24, 2019. Finally, the customer has to send the goods to different selling points from their own warehouse according to the retailer’s order. It will take some time on the road, and the real spring project will be sold in the store. The date is February 5th. By analogy, the order time of 1st Time Buy orders is traceable according to the project (Spring 2019, Christmas Promotion, Fall 2018, etc.). Orders for Christmas promotional items will be placed no later than the end of May, and orders for Fall 2018 will be placed no later than the end of April. We are now working backwards according to the order dates of different projects, and the third point of business tracking will naturally appear. For example, if you focus on Christmas promotional gifts, you must recommend new Christmas promotional gifts before April each year, and it is better to have a stronger offensive in this stage from March to April. Because at this stage, Buyer and Sales discussed preparations and confirmed it was the Christmas promotion for this year. The best sales months for spring new product designs are June-July, the Buy Trip promotion in the first half of the year is February-March, and the Buy Trip recommendation in the second half is July-August. The above are the 1st Time Buy order rules and business tracking points for common consumer goods.

03Order rules for return orders

The ordering rule of Replenished Order mainly affects the supplier’s material preparation and production scheduling. Customers will make plans and arrange orders according to the supplier’s production cycle, their own warehouse inventory and sales expectations.

For familiar and old customers, the business can inquire about the quarterly or annual Order Forecast, and order materials and arrange production based on this. Centralized material procurement can reduce the cost of purchasing materials, timely sales supplement to reduce additional losses such as delivery delays, and reasonable inventory to reduce unnecessary inventory costs.

It can be seen that accurate expectations and planning are very useful. However, beware of the unreasonable Order Forecast of the guests. Sometimes the excess inventory caused by the excessive optimism of the guests may shamelessly ask you to share the burden.

As for engineering products, I am not too familiar with it. Here is an example:

For example, when purchasing furniture for a five-star hotel, the hotel started budgeting and bidding when the project was first established. Suppliers of various products must participate in the bidding, such as furniture, building materials, doors and windows, floors, bath products, towels and curtains.. ….Wait, after all of them were selected, the real construction of the hotel began, and the hotel was built within a year and a half. During this process, we will bid again to discuss the contract details. When the hotel is about to be built, we will start to finalize the purchase orders for some furniture items one after another.

In this process, there are many back and forth talks, constant tossing, constant proofing, and even constant revision and improvement of the plan; from the first bid to the final signing of the contract for supply, it basically takes 1.5- 2 years. So if you know this rhythm, you should know which stage you are in and where to put your strength.

To put it bluntly, this is to grasp the tracking business from the point of time. Buyer and Sales are busy with the project according to the established point of time every year to see if the interested person can seize the opportunity at the node.

Buying and selling is inseparable from selling. The ultimate purpose of buying and selling is to realize the value of the product. The responsibility of selling is to support, assist, and even guide buying to fully maximize the value of the product.

Post time: Aug-31-2022