Recently, netizens exclaimed that “Vietnam has surpassed Shenzhen”, and Vietnam’s performance in foreign trade exports has attracted much attention. Affected by the epidemic, Shenzhen’s export value in the first quarter of 2022 was 407.66 billion yuan, down 2.6%, while Vietnam’s export value in the first quarter of 2022 was 564.8 billion yuan. As we all know, Shenzhen is China’s largest export city, especially in terms of electronic products. In recent years, Vietnam’s foreign trade exports have developed rapidly. The main export markets are the United States and the European Union. Mobile phones and other electronic products are the main commodities that Vietnam exports to the European Union. Vietnam currently has a large export demand, but the quality management level of suppliers is generally low. It is particularly important to test the quality of Vietnam’s export products or outsourcing orders through third-party inspection.

As one of the most popular electronic products among the masses, the convenience and practicality of wireless Bluetooth headsets are self-evident. The inspection standard of Bluetooth headset not only affects its experience, but also affects the wearer’s hearing and health problems. Therefore, the inspection of wireless Bluetooth headset is very important. The following are the inspection standards and methods for the bluetooth headset by the warehouse inspector.

Wireless bluetooth headset inspection 1. Inspection Tools 2. Inspection Conditions 3. Visual Inspection 4. On-site General Item Test 4.1 Barcode Scanning (Outer Box Barcode) 4.2 Barcode Scanning (Sales Packaging Barcode) 4.3 Odor Inspection (Sales Packaging) 4.4 Odor Inspection (Product) 4.5 Product Size and Weight 4.6 Coating Adhesion Test 4.7 Nameplate Friction Test 4.8 Battery Voltage Test 4.9 Internal Workmanship Test 5. Headphone Speaker Impedance Test 6. Headphone Speaker Sensitivity Test/Frequency Response Test 7. Headphone LED Indicator Test 8. Headphone On/Off Test 9 . Headphone pairing test 10. Headphone use function test 11. Headphone call quality test 12. Headphone wireless distance test 13. Headphone charging function test 14. Packaging and component inspection

1. Validation tools Ruler, vernier caliper, plug gauge, comparison sheet, sample, barcode scanner, anti-static gloves or finger cots, dust cloth, alcohol, knife, sealing tape, clear tape (3M 600), a Bluetooth-enabled cell phone.

2. Inspection conditions

Temperature: 15-35℃;

Humidity: 20%-75%;

Atmospheric pressure: 86kPa-106kPa

Vision: The inspector’s vision requirement is not less than 1.0 (including corrected vision);

Distance: The distance between the human eye and the surface of the mobile phone under test is 300mm±50mm;

Lighting: 40W fluorescent lamp (the light source is directly above the detector), the light source is 500mm-550mm away from the object to be tested, and the light intensity is 1000±200Lux;

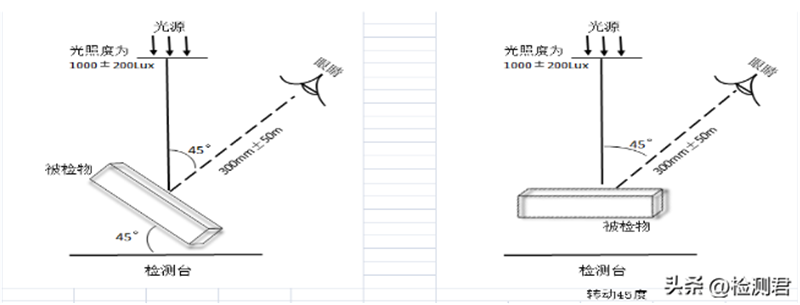

Viewing angle: The product viewing surface and the desktop form a 45-degree angle, and rotate 45 degrees up, down, left, and right (as shown in the figure below):

Wireless bluetooth headset inspection 1. Inspection Tools 2. Inspection Conditions 3. Visual Inspection 4. On-site General Item Test 4.1 Barcode Scanning (Outer Box Barcode) 4.2 Barcode Scanning (Sales Packaging Barcode) 4.3 Odor Inspection (Sales Packaging) 4.4 Odor Inspection (Product) 4.5 Product Size and Weight 4.6 Coating Adhesion Test 4.7 Nameplate Friction Test 4.8 Battery Voltage Test 4.9 Internal Workmanship Test 5. Headphone Speaker Impedance Test 6. Headphone Speaker Sensitivity Test/Frequency Response Test 7. Headphone LED Indicator Test 8. Headphone On/Off Test 9 . Headphone pairing test 10. Headphone use function test 11. Headphone call quality test 12. Headphone wireless distance test 13. Headphone charging function test 14. Packaging and component inspection

3. Validation tools Ruler, vernier caliper, plug gauge, comparison sheet, sample, barcode scanner, anti-static gloves or finger cots, dust cloth, alcohol, knife, sealing tape, clear tape (3M 600), a Bluetooth-enabled cell phone.

4. Inspection conditions

Temperature: 15-35℃;

Humidity: 20%-75%;

Atmospheric pressure: 86kPa-106kPa

Vision: The inspector’s vision requirement is not less than 1.0 (including corrected vision);

Distance: The distance between the human eye and the surface of the mobile phone under test is 300mm±50mm;

Lighting: 40W fluorescent lamp (the light source is directly above the detector), the light source is 500mm-550mm away from the object to be tested, and the light intensity is 1000±200Lux;

Viewing angle: The product viewing surface and the desktop form a 45-degree angle, and rotate 45 degrees up, down, left, and right (as shown in the figure below):

5.Headphone speaker impedance test

Measure the impedance of the left and right channels of the earphone respectively, generally 8-32 ohms, and the impedance on the left and right sides must be the same.

6.Headphone speaker sensitivity test/frequency response test

Use the tester to test the sensitivity of the earphone speaker, and the frequency response of the speaker should meet the customer’s specification requirements.

7.Headphone LED indicator test

The response status of the indicator lights during the process of turning on, turning off, pairing, incoming calls, calls, charging, and full charging should be consistent with the specifications provided by the customer.

8.Headphone on/off test

Press the multi-function button for more than 4 seconds, the headset should be able to automatically turn on and off.

9.Headphone pairing test

Press and hold the multi-function button, the headset enters the pairing state, and can be paired with a Bluetooth mobile phone.

10.Headphone use function test

Detect the functions of the headset according to the instructions, such as answering calls, volume adjustment, voice dialing, key functions, intelligent induction, etc.

11.Headphone call quality test

The headset has no noise or echo during the call, the receiver has no “broken sound”, and the headset has no obvious fever within 10 minutes of the call.

12.Headphone wireless distance test

After the headset is connected to the phone, it should work normally within 33 feet/10 meters (or according to the instructions).

13. Headphone charging function test

Using the corresponding charger, the headset can be charged normally, the display light is normal, and the body does not heat; the charging time reaches the specified time, such as 1.5 hours, the green light is on (indicating that it is fully charged).

14.Packaging and component inspection

The color and quantity on the packaging are consistent with the product list;

The size of the package is consistent with the packaging guidelines;

The color box/PVC bag is not damaged;

The surface printing is correct and there is no bad phenomenon;

Instructions, warranty cards, etc. are not missing or damaged.

Post time: Oct-21-2022