There are many types of furniture, such as solid wood furniture, wrought iron furniture, plate furniture, etc. Many furniture need to be assembled by consumers themselves after purchase. Therefore, when the inspector needs to inspect the assembled furniture, he needs to assemble the furniture on site, so what are the equipment steps for disassembling and assembling the furniture, how to operate it on site, and what precautions should be taken. Below is a summary of some useful information that should help you.

Equipment steps and key requirements for furniture inspection

1. Quantity of on-site assembly inspection 1) The inspector must assemble at least one set of products independently according to the assembly instructions. If the product size is too large, the factory personnel must help, be sure to ensure that the connection and matching parts are installed and operated by the inspector himself. 2) The assembly of other products can be completed by factory personnel, but it needs to be completed under the supervision of the inspector throughout the whole process. Pay attention to check the whole process of product assembly, not just focus on the final result of the assembly. The cargo man cannot leave the assembly site, and the quantity of equipment is required by the inspection (WI).

Equipment steps and key requirements for furniture inspection

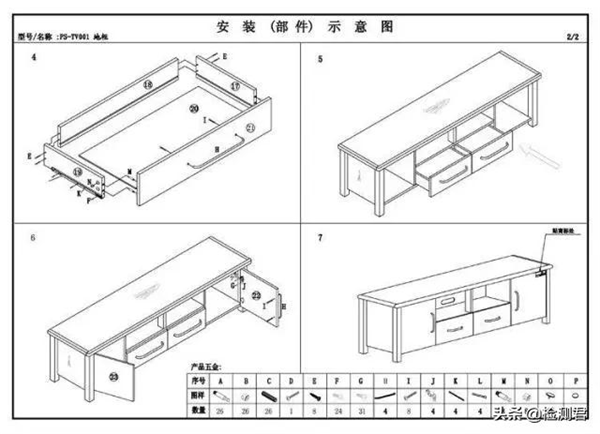

2.On-site assembly steps and precautions 1) On-site equipment must be installed in strict accordance with the assembly instructions provided with the product. During the assembly process, check whether the steps in the assembly instructions are correct, whether each component meets the technical requirements, whether the fit is tight, and whether the hole positions are correct. , whether the product is firm, and whether it needs to use external tools (generally not allowed, depending on the requirements of the manual) 2) Before assembly, identify the number of pieces of the product, open the carton package, put the hardware package in a separate location and count to avoid missing or mixed with accessories from other products. 3) First check whether the number and size of the parts are consistent with the number marked on the manual, and pay attention not to replace the unsuitable parts when assembling. 4) Carefully read the assembly instructions, first separate the main components in the order of assembly, and visit the panels separately for installation. It is best to take pictures of these panels.

Equipment steps and key requirements for furniture inspection

5) Prepare installation tools such as screwdrivers, wrenches, etc. During the assembly process, strictly follow the assembly steps in the product assembly instructions. Inspectors need to pay special attention: factory personnel often rely on experience during assembly, and fail to install in full accordance with the steps in the instructions. This approach cannot test whether the equipment instructions are reasonable and complete. If such a situation is found, it must be stopped/corrected immediately. At the same time, it is best to install one by one, not several at the same time, so as not to supervise in place. 6) Generally speaking, the assembly process of most products can be divided into four stages: The first step is to form the skeleton of the product. During this process, attention should be paid to whether the connection holes of the skeleton are correct, and whether the installation of fasteners such as bolts is smooth, the connector should be locked, and the gap of the skeleton should be uniform. The second part is to install the fixed and combined parts of the reinforcing structure on the skeleton. During this process, pay attention to the hardware accessories, especially the screws, so that all the parts and fasteners should be put on, and check whether the connection holes are suitable. It should be noted that the phenomenon of screw hole dislocation often occurs in the second process. The third part is to install the guide device or the movable parts connected by hinges in the corresponding positions. Note that the disassembly and assembly of furniture parts can be completely disassembled and assembled for multiple times without damage. In this link, it is necessary to pay attention to whether these parts have been connected once. There are problems of loose screw holes and damaged parts. The fourth part, installation of minor or decorative parts or accessories. During this process, pay attention to whether the length of the screw meets the requirements, whether the decorative accessories can be reinforced tightly, whether the hole position is appropriate when locking the screw, and the product cannot be scratched during the process, and the accessories cannot be loosened.

Equipment steps and key requirements for furniture inspection

Common problems 1. There are missing parts in the product, especially the hardware accessories in the small package. The fitting holes on the plate are filled with paint, and the hardware cannot be put in smoothly 4. The hardware fittings cannot be locked, and the product is not firm 5. When locking the hardware fittings, the parts are deformed, cracked, damaged, etc. 6 . The functional moving parts cannot be pushed and pulled smoothly. 7. The connecting parts are damaged, and the surface of the hardware accessories is rusted. 8. The gap between the parts during assembly is too large, or the gap is uneven

Equipment steps and key requirements for furniture inspection

Product quality requirements and inspection methods 1. Inspection methods Tool measurement, visual inspection, hand touch, inspect the product according to the product assembly technical requirements and the drawing size and shape 2. The inspection distance should be under natural light or near natural light (for example: 40W fluorescent lamp), Sight distance 700-1000mm3. Appearance inspection concerns 1) Welding, rivets, tenon joints, etc. used for fixed parts should not be loose. 2) Screws and hardware connection parts should not be loose. 3) The surface of hardware accessories is free of scratches, plated (The coating) layer is firm, without falling off or rusting. 4) The load-bearing parts and moving parts should not have cracks, knots, worm holes and other defects. 5) Metal pipe fittings should be free of cracks and scabs 7) Welded parts should be free of de-soldering, virtual welding, and welding penetration 8) Welded parts should be free of pores, weld flashes, and spatters 9) Riveted parts should be riveted smoothly and without hammer marks 10) Coating should No scorching, blistering, pinholes, cracks, burrs, scratches 11) The coating of metal parts should be free of exposed bottom, bumps, obvious sagging, bumps, wrinkles, flying paint 12) The surface of the finished product has no scratches, scratches (touches) ) Injury 13) The overall structure of the product is firm, the ground is balanced, the components are not loose when shaken, the seams are tight, and there is no obvious gap 14) The lens and glass door are clean and free of glue marks, and the glue or joint is tight and firm 15) Any hardware that is often opened Accessories, such as hinges, shrinks, drawer slides, etc., require flexible switches. 16) The solid wood components have no rot, worm holes, cracks, etc., the color and wood grain direction are consistent, and the moisture content meets the requirements. 17) The coating of wooden parts should not have Wrinkled skin and paint leakage: The coating or coating of metal parts should be free of peeling, embroidery, and paint leakage. 18) The coating of wooden parts should be smooth and smooth, without scratches, white spots, bubbling, sagging, and obvious color difference. 19) No hollow, loose, moth-eaten, cracked, chipped, dented, nailed, pierced, etc., are not found in the panel components. 20) The surface color is uniform, whether it is a single piece of different positions or the entire system, the color is required Consistent 21) There are no obvious tool marks on the surface, knife marks, drag marks, cracks, cracks, sand black, sag Adjust the door to keep the door flush 23) Glass and mirrors must not be shaken, loose after installation Drawing requirements, the appearance size is within the allowable size tolerance range

Equipment steps and key requirements for furniture inspection

Common hardware accessories for disassembly and assembly of furniture Hardware accessories are generally used to fix and connect the structure. Common connectors in furniture include hinges, connectors (eccentric, permanent), drawer slides, sliding door slides, Handles, locks, latches, door suctions, partition supports, clothes hangers, pulleys, feet, bolts, wood screws, dowels, round nails, etc.

Equipment steps and key requirements for furniture inspection

1. The hinge hinge is the main structure connecting two moving parts, mainly used for the opening and closing of the cabinet door. It is divided into open hinge and dark hinge It leaks on the surface of furniture, and the hinge can be used for built-in doors and folding doors.

Equipment steps and key requirements for furniture inspection

2) Concealed hinge The concealed hinge is rotated by the connecting rod, and it is hidden inside the furniture and does not leak out during installation.

Equipment steps and key requirements for furniture inspection

2. Connectors Connectors are also called fixed connectors, which have a direct impact on the structure and firmness of furniture products. They are mainly used for the connection of side panels, horizontal panels and back panels of cabinet furniture, so that furniture panels can be fixed. , the connecting rod includes an eccentric connecting piece and a permanent connecting piece. 1) The eccentric connector adopts eccentric distance to connect the horizontal plate and the side plate, such as the floor and the side plate, and the bottom plate can be installed from above or from the side.

Equipment steps and key requirements for furniture inspection

2) The permanent connector is composed of two parts: a screw and a sleeve with a spring steel sheet. After the connection is pressed by hand, the object is permanently connected, which is characterized by a very firm connection.

Equipment steps and key requirements for furniture inspection

3. Drawer slides Drawer slides are generally made of iron baking varnish or iron galvanized materials. According to different methods in East China, they can be divided into pulley type or ball type, etc. According to the distance of the drawer pulling out of the cabinet, it can be divided into single section Track, double track, triple track.

Equipment steps and key requirements for furniture inspection

4. A type of fastener consisting of a head and a bolt (a cylinder with an external thread), which needs to be matched with the curtain to fasten and connect two parts with through holes. This connection form called bolted connection.

5. Round rod and tenon board furniture is one of the commonly used assembly and connection accessories. Its shape is like a round rod. It is generally made of wood. The wooden tenon in the disassembly and assembly furniture plays the role of positioning. The commonly used diameters are 6mm, 8mm, 10mm, 12mm, Lengths are 20mm, 25mm, 30mm, 35mm, 40mm, 50mm.

Equipment steps and key requirements for furniture inspection

6. Other connector screws, self-tapping screws, nuts, washers, spring washers, cylindrical nuts, double thread nuts, handles, etc.

Post time: Jul-19-2022