When exporting, the main concerns of general enterprises during the loading process are incorrect cargo data, damage to the cargo, and inconsistency between the data and customs declaration data, resulting in customs not releasing the goods. Therefore, before loading, the shipper, warehouse, and freight forwarder must coordinate carefully to avoid this situation.

Cargo inventory 1

1. Carry out on-site inventory with the customer's packing list, and verify that the product quantity, batch number, and accessories are consistent with the customer's packing list. 2. The cargo packaging is inspected to meet customer requirements and can protect the cargo during transportation. 3. Check the container bill of lading information to ensure that the container number, product batch, and packing information are consistent and are the planned shipment batches.

Container inspection 2

1. Container type: Containers that comply with ISO 688 and ISO 1496-1 standards.

2. Common sizes: 20-foot cabinet, 40-foot cabinet or 40-foot high cabinet.

3. Check whether the container is qualified or not.

#a. Container external inspection

①. The container must carry a valid 11-digit number that complies with the requirements of IQS 6346.

②. Containers must carry a valid container safety nameplate (CSC nameplate).

③. There are no self-adhesive labels (such as dangerous goods labels) left behind by the previous batch of goods.

④. Cabinet doors must use original assembly hardware and not be repaired with epoxy resin.

⑤.The door lock is in good condition.

⑥. Whether there is a customs lock (carried by the container driver).

# b.Container internal inspection

①.Completely dry, clean and odorless.

②.Ventilation holes cannot be blocked.

③. There are no holes or cracks in the four walls, top layer, and bottom.

④. Rust spots and indentations shall not exceed 80 mm.

⑤. No nails or other protrusions that may damage the goods.

⑥. There is no damage to the binding area. ⑦.Waterproof.

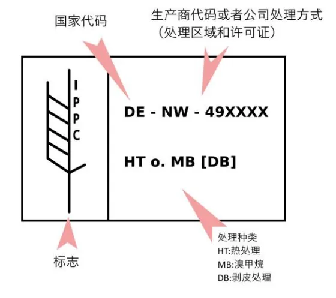

#c. Cargo pallet inspection

Wooden pallets must have fumigation certificates and phytosanitary certificates, can be forked from all sides, and have 3 treated pallets:

#The best way to use pallets

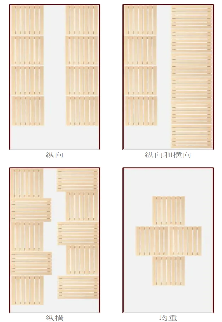

①.When similar goods are placed on the same pallet, the overlapping type is better than the staggered type.

Because the staggered type shakes less when moving, the overlapping type can evenly stress the four corners and walls of the carton, thereby improving the bearing capacity.

②.Place the heaviest goods at the bottom and keep them parallel to the edge of the pallet.

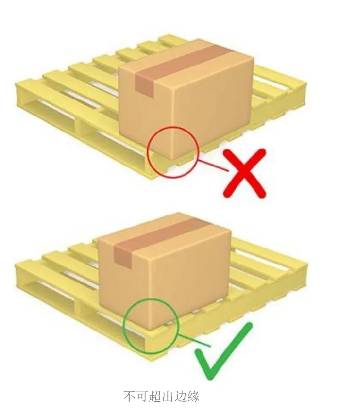

③.The goods should not exceed the edge of the pallet to avoid being easily damaged during transportation and loading and unloading.

④. If the top layer of the pallet is not full, place the cartons on the outer edges to increase stability and avoid pyramid stacking as much as possible.

⑤. It is recommended to protect the edges of the goods with cardboard. Use stretch film to wrap the pallet tightly from top to bottom, and tie the pallet with nylon or metal strapping. The strapping should go around the bottom of the pallet and avoid wrapping.

⑥. Sea transportation: non-stacking palletized goods are not higher than 2100 mm. Air transportation: palletized goods are not higher than 1600 mm.

Loading goods into container 3

To prevent the goods from being damaged due to shaking, vibration, bumping, rolling, and deviation during transportation. You need to do the following:

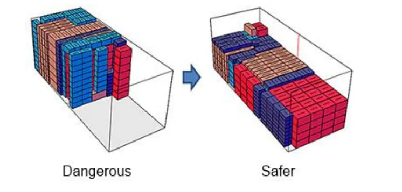

#a. Confirm that the center of gravity is in the middle of the container and the weight does not exceed the container's carrying capacity.

(Palletized goods)

( Non-palletized goods)

When the container is not full, all goods cannot be placed at the back of the goods to cause the center of gravity to shift backward. Rearward shifting of the center of gravity may cause casualties to people around the cargo, and the cargo may fall out when the door is opened, posing danger to unloading personnel, and may damage or destroy cargo and other property.

#b. Cargo bundling and reinforcement

#c. Fully support the load, fill the gaps to prevent load drift, and avoid unnecessary waste of container space.

Cargo loading completed 4

#a. After loading the container, take photos or videos to record the status of the goods in front of the container door.

#b. Close the container door, seal it, and record the seal number and container number.

# c. Organize relevant documents and send the documents and packing cabinet diagrams by email to relevant departments of the company and customers for record keeping.

Post time: May-28-2024