Factory inspection issues that foreign trade export enterprises are most concerned about before factory inspection

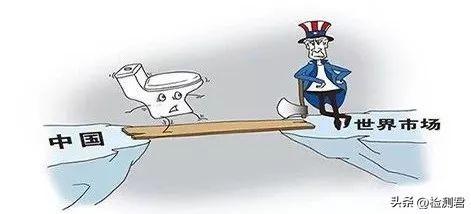

In the process of global trade integration, factory inspection has become a threshold for foreign trade export enterprises to connect with the world, and through the continuous development in recent years, factory inspection has gradually become well known and fully valued by enterprises. About one-third of enterprises in mainland China lost foreign trade orders because they failed to pass the factory inspection. Therefore, how to correctly understand the factory inspection standards, implement effective plans, meet the requirements of factory inspections, break through trade barriers, and maintain a competitive advantage has also become a key issue. A major problem that many enterprises have to solve under the new form.

Without a qualified COC report, nothing is discussed, because for foreign investors, the main purpose of factory inspection is to protect their company’s brand image. Therefore, before placing an order, the factory will be checked by itself or by a third-party notary. After confirming that there are no major or serious problems in the factory, the factory can be included in the list of qualified suppliers before placing an order and cooperating for a long time.

Some export companies are very happy to receive orders, but they are very nervous to have a factory inspection. However, it is undeniable that a factory inspection can improve production conditions, enhance the overall image of the factory, and obtain more foreign trade orders. Therefore, factory inspection is very important for factories.

The following summarizes some of the most concerned questions of enterprises before the factory inspection to answer them.

1 Is it difficult for customers to audit the factory, how to pass?

As long as the preparation work is sufficient, the materials and training are done! It is no problem to pass the factory inspection.

2 The scale of the factory is not large. If an inspection is required, can it pass?

The factory must not have a three-in-one place (fatal point); the factory audit is to look at the actual situation of the factory and the management of water products, as long as the factory has the basic production process and basic machinery. There are many factories and many processes are outsourced, but they are assembled in the factory, which is also possible. Customers will not pay attention to whether the machine is new or old. The key is to look at the management of water quality, and the content of management of water quality and benefits can be reflected through documents. This is the reason why some factories have poor conditions and can still pass the factory inspection.

3What hardware conditions should the factory audit have?

This depends on the factory inspection project. Under normal circumstances, the inspection of social responsibility, mainly fire protection, the production area of more than 400 square meters, and the number of people producing more than 30 people at the same time must have more than two escape exits. For anti-terrorism inspection, the factory must have a wall of more than 2M around it (if it cannot reach the height, it can be built with other things or it can be left untreated. This is a small problem). The quality inspection basically depends on some records of the factory. Others The on-site problems are solved very well!

4 About the number of people in the factory?

The factory inspection generally does not require the number of people, because it is not well linked to the order volume, and customers generally only record the proportion of their orders in our factory. Under normal circumstances, factories can try to declare as few people as possible. In this way, the application fee and the workload during the factory inspection can be reduced, and some temporary workers and those who have been fired can be ignored, and it is enough that they do not show up during the factory inspection. Some small factories with more than a dozen people can pass the factory inspection.

5 How to prepare the factory inspection documents, they need to look at one year’s documents?

The key points, the core, must be grasped when handling the factory audit data. There are no common-sense and low-level mistakes in the documents and materials. It is the most critical to prepare the core content and materials, and the most important links are seized. It does not matter if other minor problems occur!

6 Does the factory inspection and rectification cost a lot of money?

The factory inspection is mainly to look at the data, of course, the site must also be combined with rectification. Basically, the social responsibility of the inspection is mainly for fire protection facilities and labor protection supplies (this cost is not large, and it can generally be controlled within 1-2 thousand yuan). According to the actual situation of the factory, we will propose rectification to save costs for the factory as much as possible. Others basically cost nothing!

7 What if the employee doesn’t cooperate?

It is true that some factory employees do not cooperate. Factory managers must communicate well in advance and do a good job in employee training.

8 If the auditors are very strict and make things difficult, what should I do?

Some factory information seems to be ready, but maybe the factory information is too simple and unreal. This often leads to “special care” by the auditor. In addition, the audit methods and styles of different notary firms are also different, and the standards of customers are also different. TTS is familiar with the requirements of various factory inspections, auditing the characteristics of the company and good public relations channels, which can effectively avoid risks.

9 Is the factory inspection consulting company reliable? Are the fees high?Formal factory inspection coaching and training companies rely on good service and reputation to survive! With the help of factory inspection guidance, the factory can help the factory to build the factory inspection structure and system in a short time, compile accurate data documents, and help the factory to improve some certificates. It can be said to be a time-saving, labor-saving and cost-saving service!

However, when choosing a counseling and consulting company, you must keep your eyes open and look carefully. The development of the Internet has brought convenience to everyone, and it has also given many liars an opportunity to take advantage of the opportunity. If you want to take the opportunity to audit the factory and consult a piece of the pie, there are overwhelming advertisements and mailboxes on the Internet. There are all kinds of promotions here, and all the promises on Baidu are guaranteed to pass. The average factory really doesn’t know how to choose, and some don’t even have a business license or office location, so they just make up a name and advertise on the Internet to receive business.

Be sure to confirm whether the business license is for management consulting. Although some have business licenses, they are not engaged in management consulting work, and their professionalism can be imagined. These individuals or companies usually cheat the factories at low prices. Maybe they will disappear after receiving a part of the fee. When it comes to auditing the factory, they can no longer contact anyone. At this time, I want to cry without tears. Not only lost some consulting fees, but also delayed orders, delayed delivery, affected the image of the factory in the minds of customers, and even lost customers. Xiaobian sincerely warns enterprises that factory inspections are risky, and you need to be cautious when choosing consulting companies.

Post time: Sep-17-2022