The common inspection method for cloth is the “four-point scoring method”. In this “four-point scale”, the maximum score for any single defect is four. No matter how many defects there are in the cloth, the defect score per linear yard shall not exceed four points.

A four-point scale can be used for woven knitted fabrics, with 1-4 points deducted depending on the size and severity of the defect

How to use the four-point system to conduct professional inspection of textile fabrics?

The standard of scoring

1. Defects in warp, weft and other directions will be evaluated according to the following criteria:

One point: the defect length is 3 inches or less

Two points: the defect length is greater than 3 inches and less than 6 inches

Three points: the length of the defect is greater than 6 inches and less than 9 inches

Four points: the defect length is greater than 9 inches

2. The scoring principle of defects:

A. Deductions for all warp and weft defects in the same yard shall not exceed 4 points.

B. For serious defects, each yard of defects will be rated as four points. For example: All holes, holes, regardless of diameter, will be rated four points.

C. For continuous defects, such as: rungs, edge-to-edge color difference, narrow seal or irregular cloth width, creases, uneven dyeing, etc., each yard of defects should be rated as four points.

D. No points will be deducted within 1″ of the selvage

E. Regardless of the warp or weft, no matter what the defect is, the principle is to be visible, and the correct score will be deducted according to the defect score.

F. Except for special regulations (such as coating with adhesive tape), usually only the front side of the grey fabric needs to be inspected.

2. Inspection

1. Sampling procedure:

1) AATCC inspection and sampling standards:

A. Number of samples: multiply the square root of the total number of yards by eight.

B. Number of sampling boxes: the square root of the total number of boxes.

2) Sampling requirements:

The selection of papers to be examined is entirely random.

Textile mills are required to show the inspector a packing slip when at least 80% of the rolls in a batch have been packed. The inspector will select the papers to be inspected.

Once the inspector has selected rolls to be inspected, no further adjustments may be made to the number of rolls to be inspected or the number of rolls that have been selected for inspection. During inspection, no yardage of fabric shall be taken from any roll except to record and check color.

All rolls of cloth that are inspected are graded and the defect score is assessed.

2. Test score

1) The calculation of the score

In principle, after each roll of cloth has been inspected, the scores can be added up. Then, the grade is assessed according to the acceptance level, but since different cloth seals must have different acceptance levels, if the following formula is used to calculate the score of each roll of cloth per 100 square yards, it only needs to be calculated at 100 square yards According to the specified score below, you can make a grade assessment for different cloth seals.

A = (Total points x 3600) / (Yards inspected x Cutable fabric width) = points per 100 square yards

2) The acceptance level of different cloth species

The different types of cloth are divided into the following four categories

| Type | Kind of cloth | Single Volume Scoring | Whole critique |

| Woven fabric | |||

| All man-made cloth, polyester /

Nylon/Acetate Products |

Shirting, man-made fabrics,

worsted wool |

20 | 16 |

| Denim

Canvas |

Poplin/Oxford striped or gingham shirting, spun man-made fabrics, woollen fabrics, striped or checked fabrics/dyed indigo yarns, all specialty fabrics, jacquards/Dobby corduroy/velvet/stretch denim /Artificial Fabrics/Blends | 28 | 20 |

| Linen, muslin | Linen, muslin | 40 | 32 |

| Dopioni silk/light silk | Dopioni silk/light silk | 50 | 40 |

| Knitted fabric | |||

| All man-made cloth, polyester/

Nylon/Acetate Products |

Rayon, worsted wool, blended silk | 20 | 16 |

| All professional cloth | Jacquard / Dobby corduroy, spun rayon, woolen textiles, dyed indigo yarn, velvet / spandex | 25 | 20 |

| Basic knitted fabric | Combed cotton/blend cotton | 30 | 25 |

| Basic knitted fabric | Carded cotton cloth | 40 | 32 |

A single roll of cloth exceeding the specified score shall be classified as second-class.

If the average score for the entire lot exceeds the specified score level, the lot shall be deemed to have failed the inspection.

3. Inspection Score: Other Considerations for Evaluating Cloth Grades

Repeated flaws:

1), any repeated or recurring defects will constitute repeated defects. Four points must be awarded for each yard of cloth for repeated defects.

2) No matter what the defect score is, any roll with more than ten yards of cloth containing repeated defects should be regarded as unqualified.

How to use the four-point system to conduct professional inspection of textile fabrics

Full width defects:

3) Rolls containing more than four full-width defects in every 100y2 shall not be rated as first-class products.

4) The rolls that contain more than one major defect per 10 linear yards on average will be regarded as unqualified, no matter how many defects are contained in 100y.

5) The rolls containing a major defect within 3y of the cloth head or cloth tail should be rated as unqualified. Major defects will be considered three or four points.

6) If the cloth has obvious loose or tight threads on one selvedge, or there are ripples, wrinkles, creases or creases on the main body of the cloth, these conditions cause the cloth to be uneven when the cloth is unfolded in the usual way. Such volumes cannot be graded as first class.

7) When inspecting a roll of cloth, check its width at least three times at the beginning, middle, and end. If the width of a roll of cloth is close to the specified minimum width or the width of the cloth is not uniform, then the number of inspections for the width of the roll should be increased.

8) If the roll width is less than the specified minimum purchase width, the roll will be regarded as unqualified.

9) For woven fabrics, if the width is 1 inch wider than the specified purchase width, the roll will be regarded as unqualified. However, for elastic woven fabric, even if it is 2 inches wider than the specified width, it can be qualified. For knitted fabrics, if the width is 2 inches wider than the specified purchase width, the roll will be rejected. However, for the frame knitted fabric, even if it is 3 inches wider than the specified width, it can be regarded as acceptable.

10) The overall width of the cloth refers to the distance from the outer selvage at one end to the outer selvage at the other end.

Cutable fabric width is the width measured without selvedge and/or stitcher pinholes, unprinted, uncoated or other untreated surface portions of the fabric body.

Color difference evaluation:

11) The color difference between rolls and rolls, batches and batches shall not be lower than the four levels in the AATCC gray scale.

12) During the cloth inspection process, take 6~10 inch wide color difference cloth boards from each roll, the inspector will use these cloth skins to compare the color difference within the same roll or the color difference between different rolls.

13) The color difference between edge-to-edge, edge-to-middle or cloth head-to-cloth tail in the same roll shall not be lower than the fourth level in the AATCC gray scale. For inspected rolls, each yard of fabric with such color-difference defects will be rated four points per yard.

14) If the fabric to be inspected does not conform to the approved samples provided in advance, its color difference must be lower than the 4-5 level in the gray scale table, otherwise this batch of goods will be regarded as unqualified.

Roll length:

15) If the actual length of a single roll deviates by more than 2% from the length indicated on the label, the roll will be regarded as unqualified. For rolls with roll length deviations, their defect scores are no longer evaluated, but must be indicated on the inspection report.

16) If the sum of the lengths of all random samples deviates by 1% or more from the length indicated on the label, the whole batch of goods will be regarded as unqualified.

Joining part:

17) For woven fabrics, the whole roll of fabric can be connected by multiple parts, unless otherwise stipulated in the purchase contract, if a roll of fabric contains a joint part with a length of less than 40y, the roll will be determined. is unqualified.

For knitted fabrics, the whole roll may be made of multiple parts joined, unless otherwise specified in the purchase contract, if a roll contains a joined part weighing less than 30 pounds, the roll will be classified as unqualified.

Weft oblique and bow weft:

18) For woven and knitted fabrics, all printed fabrics or striped fabrics with more than 2% bow weft and diagonal folds; and all wicked fabrics with more than 3% skew cannot be classified as first-class.

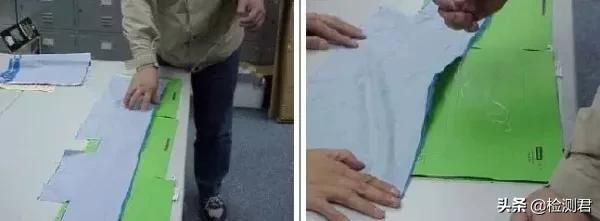

Cut the cloth along the weft direction, and try to stick to the direction of the weft bending as far as possible;

Remove the weft yarns one by one;

Until a complete weft is drawn;

How to use the four-point system to conduct professional inspection of textile fabrics

Fold in half along the warp, with the edges flush, and measure the distance between the highest point and the lowest point

How to use the four-point system to conduct professional inspection of textile fabrics

19) For woven fabrics, all printed and striped fabrics with skew greater than 2%, and all wick fabrics with skew greater than 3% cannot be classified as first-class.

For knitted fabrics, all wick fabrics and printed fabrics with a skew greater than 5% cannot be classified as first-class products.

Cloth smell:

21) All the rolls that emit odor will not pass the inspection.

Hole:

22), through the defects that lead to the damage of the cloth, no matter the size of the damage, it should be rated as 4 points. A hole should include two or more broken yarns.

Feel:

23) Check the feel of the cloth by comparing it with the reference sample. In the event of a significant discrepancy, the roll will be rated as second class, with a score of 4 per yard. If the feel of all rolls does not reach the level of the reference sample, the inspection will be suspended and the score will not be assessed temporarily.

Density:

24) In the full inspection, at least two inspections are allowed, and ±5% is allowed, otherwise it will be regarded as unqualified (although it does not apply to the 4-point system, it must be recorded).

Gram weight:

25) During the full inspection process, at least two inspections (with temperature and humidity requirements) are allowed, and ±5% is allowed, otherwise it will be regarded as a substandard product (although it does not apply to the four-point system, it must be recorded).

Reel, packing requirements:

1) No special requirements, about 100 yards in length and no more than 150 pounds in weight.

2) No special requirements, it should be reeled, and the paper reel should not be damaged during transportation.

3) The diameter of the paper tube is 1.5″-2.0″.

4) At both ends of the roll cloth, the exposed part should not exceed 1”.

5) Before rolling the cloth, fix it at the left, middle and right places with adhesive tape below 4″.

6) After the roll, in order to prevent the roll from loosening, apply 12″ tape to fix 4 places.

Post time: Jul-19-2022