Children’s umbrellas are small umbrellas specially designed for children, with an emphasis on safety, portability and fun.

Product Classification:

According to the form of opening and closing the umbrella, they can be divided into manually opened children’s umbrellas and self-opening children’s umbrellas.

I. Inspection Requirements:

1. Safety Requirements for Use

• The ends of the wire should not be exposed, and there should be no sharp tips or edges that can harm the human body in the accessible parts during use.

• There should be no pinch points during normal use.

• After the umbrella is opened and closed 400 times continuously, its components should not fall off on their own.

• The button force value of the self-opening umbrella should be between 10N and 30N.

• Opening and closing the umbrella should be flexible and easy. After opening the umbrella, the positioning device should play a positioning role, and closing the umbrella should be reliable without getting out of control.

2. Umbrella Cap or Umbrella Tip (Cover)

• The height of the umbrella cap or umbrella tip (cover) should not be greater than 50mm.

• The shape of the umbrella cap or umbrella tip (cover) should be spherical or arc-shaped, and the diameter of its top should not be less than 15mm.

3. Bead End

• The end face of the bead should be spherical or arc-shaped, and the diameter of the bead should not be less than 5mm.

• The depth that the umbrella rib extends into the bead should not be less than 15mm, and the binding firmness should not be less than 25N.

• The binding firmness between the bead of the umbrella and the umbrella surface should not be less than 20N.

4. Handle

The diameter of the handle should not be less than 15mm, and its end face should be spherical or arc-shaped.

5. Binding Firmness of Components

• The connection between the umbrella pole and the handle should be able to withstand a tensile force of 150N without displacement or falling off.

• The connection between the umbrella pole and the umbrella cap should be able to withstand a tensile force of 70N without displacement or falling off.

6. Limit of Hazardous Substances

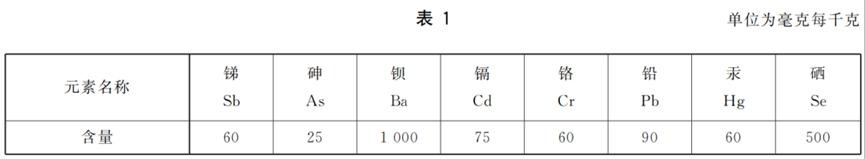

(1) Hazardous Elements in the Handle

The element contents of soluble antimony, arsenic, barium, cadmium, chromium, lead, mercury, selenium or any soluble compounds composed of these elements in the product should not exceed the values in Table 1.

(2) Formaldehyde on the Umbrella Surface

The formaldehyde on the umbrella surface should not be greater than 300mg/kg.

(3) Decomposable Harmful Aromatic Amine Dyes on the Umbrella Surface

The decomposable harmful aromatic amine dyes on the umbrella surface should not be greater than 20mg/kg.

7. Impact Strength

After the impact strength test, there should be no damage or opening phenomenon.

8. Tensile Force of the Umbrella Strap Buckle

After the umbrella strap buckle undergoes a 70N tensile force test, it should not fall off.

9. Decorative Parts

After the decorative parts undergo a 70N tensile force test, if they fall off, there should be a warning message.

II. Inspection Methods for Children’s Umbrellas

1. Safety Requirements for Use

• Visually inspect and check by hand feeling.

• Visually check whether there are pinch points during the process of opening and closing the umbrella.

• Open and close the umbrella 400 times continuously and check whether the components fall off.

• Measure the button force of the self-opening umbrella with a dynamometer.

• Hold the umbrella handle and turn it back and forth 3 times, and then open and close the umbrella 5 times.

2. Umbrella Cap or Umbrella Tip (Cover)

• Directly measure the maximum distance from the top to the cutting plane of the umbrella surface with a vernier caliper with an accuracy of 0.02mm.

• Visually inspect the shape of the umbrella cap or umbrella tip (cover) and measure the diameter of its top with a vernier caliper.

3. Bead End

• Visually inspect the end face of the bead and directly measure the diameter of the bead with a vernier caliper with an accuracy of 0.02mm.

• Fix one end of the folded umbrella with a clamp, and pull the bead end along the axial direction of the umbrella rib with a dynamometer until the bead is separated from the umbrella rib. Record the displayed value. Conduct the test 3 times respectively and take the minimum value.

• Cut a sample block with a length of 120mm and a width of 50mm from the umbrella surface, fix the bead and the umbrella surface in the upper and lower clamps of the tensile testing machine respectively, with a hollow distance of 80mm, and conduct the test at a speed of (50 ± 10)mm/min until the bead is separated from the umbrella surface. Conduct the test 3 times respectively and take the minimum value.

4. Handle

Measure it with a vernier caliper with an accuracy of 0.02mm.

5. Binding Firmness of Components

• Fix the umbrella pole and apply a 150N tensile force along the axial direction of the umbrella pole on the handle.

• Fix the umbrella pole and apply a 70N tensile force along the axial direction of the umbrella pole between the umbrella pole and the umbrella cap.

6. Limit of Hazardous Substances

• Test the migration of hazardous elements according to Appendix C of GB6675—2003.

• Test the formaldehyde content according to the method specified in GB/T2912.1.

• Test the decomposable harmful aromatic amine dyes according to the method specified in GB/T17592.

7. Impact Strength

Drop the umbrella tail and umbrella head freely 5 times at a height of 800mm from the hard ground with the umbrella tail and umbrella head facing down respectively.

8. Tensile Force of the Umbrella Strap Buckle

Use a special clamp to clamp the cap of the umbrella strap buckle, fix it in the upper clamp of the tensile testing machine, fix the other end of the umbrella strap in the lower clamp of the tensile testing machine, and conduct the test at a speed of (50 ± 10)mm/min until the cap of the umbrella strap buckle is separated from the umbrella strap. If the tensile force value exceeds the specified value of the umbrella strap buckle and the cap of the umbrella strap buckle is not separated from the umbrella strap, the test can be terminated.

9. Marking Requirements

(1) Each umbrella should have the following Chinese contents:

a) Product name

b) Name and address of the manufacturer

c) Qualification certificate for product quality inspection

d) Product implementation standard number

e) Specification and size

f) Warning message

(2) The product packaging box should have the following Chinese contents:

a) Product name

b) Name and address of the manufacturer

c) Product model

d) Specification, size and quantity

e) Production date

Post time: Dec-30-2024