1、Tire inspection and appearance quality inspection

The appearance quality of the tire should not have any appearance defects that seriously affect its service life, such as delamination between various components, sponge like, wire ring breakage, wire ring severe upward pulling, multiple cord breakage, wrinkling of the inner cord, and tire crown edge with cord. If using a cushion belt, the shape of the cushion belt should not be incomplete or the belt body should not be cracked.

2、Tire inspection, tread wear markings and markings

Each outer tire should be equipped with at least 4 visible tread wear marks at approximately equal distances along the circumference, and their height should not be less than 1.6 mm

Each tire should have markings on the shoulders on both sides indicating the location of the tread wear mark.

3、Measurement of tire inspection data

1). Measurement of main tire parameters

The specifications, load index (or level), corresponding load capacity and inflation pressure, measured rims, new tire size, maximum usage size, static load radius, rolling radius, and allowable usage of car tires should comply with GB/T2978 or relevant industry technical documents.

2). Tire inspection new tire outer edge size

The total width and outer diameter of the tire section shall comply with the provisions of Appendix A,

3). Correspondence between tire speed symbol and maximum driving speed

The correspondence between tire speed symbols and maximum driving speed should comply with the provisions of Appendix B

4). Correspondence between tire load index and load capacity

The correspondence between tire load index and load capacity should comply with the provisions of Appendix C.

4、Tire inspection safety performance inspection

According to the requirements, conduct strength performance test, bead unseating resistance test, durability performance test, low-pressure performance test, and high-speed performance test on the sampled tires.

1). Tire strength performance

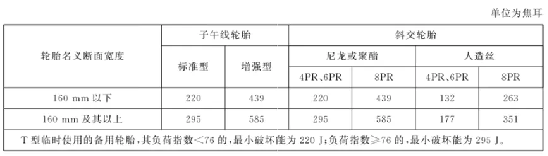

Suitable for diagonal tires, T-shaped temporary spare tires, and radial tires with a nominal aspect ratio of 50 and above. The tire strength performance test should have a failure energy of no less than the specified value in the table below for each test point.

2). Tubeless tire bead unseating resistance

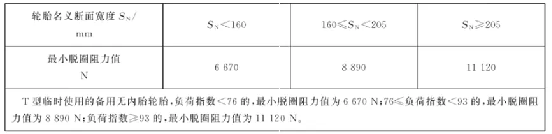

Suitable for diagonal tubeless tires, T-shaped temporary spare tubeless tires, and radial tubeless tires with a nominal aspect ratio of 50 and above. The tire's bead unseating resistance performance test should have a bead unseating resistance at each test point that is not lower than the provisions in the table below.

3). Tire durability performance

After the durability performance test, the tire pressure should not be lower than 95% of the specified initial test pressure; After the experiment is completed, there should be no delamination, ply cracking, cord stripping, cord breakage, chipping (except for PTBC snow tires), joint cracking, cracking, or abnormal deformation of the tire body in the appearance inspection. If the tire is damaged, the airtight layer should also be checked.

4). Low tire pressure performance

Suitable for radial tires, but does not include T-type temporary spare tires. After the low pressure performance test of the tire, the tire pressure should not be lower than the specified initial test pressure, 95%. After the test is completed, there should be no delamination (tread, sidewall, ply, airtight layer, belt or buffer layer, tire), ply cracking, ply peeling, ply breakage, chipping (except for PTBC snow tires), joint cracking, cracking, and abnormal deformation of the tire body in the visual inspection.

5). High speed performance of tires

After the high-speed performance test, the tire pressure should not be lower than 95% of the specified initial test pressure; After the experiment is completed, there should be no obvious delamination (tread, sidewall, ply layer, airtight layer, belt layer or buffer layer, tire bead), ply layer cracks, ply stripping, new ply cracking, flower chipping, joint cracking, cracking, or abnormal deformation of the tire during the visual inspection. Tires with a maximum speed of 300km/h or above are allowed to have surface blistering or chipping caused by blistering,

6). Tire rolling resistance performance inspection

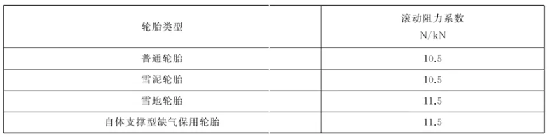

Applicable to radial tires, but does not include tires with a nominal rim diameter code of<10 and a nominal rim diameter code of>25, as well as spare tires for temporary use only, special purpose tires, racing tires, and studded tires. The rolling resistance coefficient of the tire should not exceed the maximum limit value specified in the table below.

7). Relative grip performance of tires on wet road surfaces

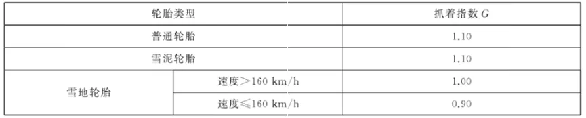

Applicable to radial tires, but does not include tires with a nominal rim diameter code of<10 and a nominal rim diameter code of>25, as well as spare tires for temporary use only, special purpose tires, racing tires, and studded tires. The relative grip index of the wet road surface of the tire should not be less than the minimum limit value specified in Table 4.

The above are the standards and methods for automobile tire inspection, including tire appearance quality inspection, main parameter measurement, safety performance inspection, etc.

Post time: Jul-10-2024