Inspection of stationery, I believe you will often encounter it. I believe that many partners have inspected gel pens, ballpoint pens, refills, staplers and other stationery. Today, I would like to share with you a simple inspection experience.

Gel pens, ballpoint pens and refills

A.The nibs of gel pens are divided into five types: ultra-fine, extra-fine, thin, medium and thick, as shown in the table below:

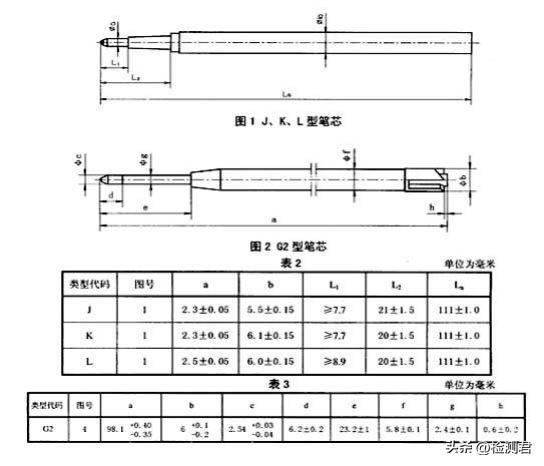

B. There are four types of refills that give shape and size data: J, K, L, and G2 (see Figures 1 to 2 and Tables 2 and 3), which are different from J, K, L, and G2 as N types.

C.Writing tester setting conditions:

(1) Writing angle: 50-70°, select the writing angle with the most coherent stitches;

(2) Writing speed: (4.5±0.5)m/min, namely (7.5±0.8)cm/s;

(3) Writing format: continuous spiral lines with a spacing of 2mm to 5mm (circumference length 10cm)

D.Testing requirements:

(1)Can write smoothly within 10cm. The writing lengths of different specifications of nibs are shown in Table 4. There should be no obvious broken lines and density changes in the beginning and end of the stitches.

(2) Permeability: The sample paper is placed in the test environment for 24 hours, and there is no obvious trace on the back of the paper by visual inspection.

(3) Dryness: Draw a straight line on the test paper according to the above-mentioned writing load, angle, and speed. After 20 seconds, wipe the straight line with an eraser vertically. The stitches should be free of stains.

(4) Reproducibility: Copy the sample paper with a copying device, and the copying lines remain visible.

(5) Water resistance: After the sample paper is placed in the test environment for 2 hours, it is immersed in distilled or deionized water for 1 hour, and the stitches remain visible after drying. This item is optional and applies to gel pens and refills marked “Water Resistant” (WR).

(6) Light fastness: Expose the sample paper and the blue wool standard sample (partially covered) under the fading meter or xenon lamp until the color difference between the exposed and unexposed No. 3 blue wool standard sample reaches level 4 of the gray sample card, the line traces remain visible.

(7) Intermittent writing: After the unused test pen (without the pen cap) is out of water normally, after placing it horizontally for 24 hours under the test environment conditions, draw a straight line with the hand, and write a continuous line within 10cm.

(8) Preservability: recently manufactured, unused test pens (with pen caps) are placed horizontally at a temperature of (40±2)°C and a relative humidity of (55±5)% for 90 days, and they are tested for writing performance and meet the requirements .

summary:

1. For plug-in neutral and ballpoint pens, the fit between the cap and the barrel is required to be moderate. Generally, hold the pen with one hand, push the cap with your thumb, and push it out. Otherwise, it is considered a tight fit.

2. For pens with a back seal on the pen barrel, it is required that the back seal cannot be pulled out easily to prevent children from swallowing them by mistake. The BS7272-test is required, and the test method is as follows:

a. Pen cap safety requirements:

①Requirements for the size of the pen cap: the pen cap cannot pass through a specific ring gauge or the pen cap cannot pass through the ring gauge at least 5mm. The diameter of the ring gauge is 16mm and the thickness is at least 19mm;

②Requirements for the ventilation area of the pen cap: at least 6.8m ㎡, if it is a single hole, it requires 3.4 m ㎡;

③Pen cap ventilation flow requirements: at least 8L/Min at 1.33KPa.

b. Requirements for the back of the pen:

① Requirements for the size of the back plug: the back plug cannot pass through a specific ring gauge, the diameter of the ring gauge is 16mm, and the thickness is at least 19mm;

② The back plug protrudes from the end of the pen, and the back plug should withstand a minimum force of 50N;

③ The back plug is completely recessed into the end of the pen and should withstand a minimum force of 10N;

④ Requirements for the minimum size of the protruding end of the back plug: the length of the part that can be grasped should not exceed 1MM, and the overall length should not exceed 3MM;

⑤ Requirements for the ventilation flow rate of the rear plug: at 1.33KPa, at least 8L/Min is met, and the rear plug should withstand a minimum force of 10N.

3. For pens with clips, the clip elasticity test should be done. It is required to be able to hold three pieces of 80g A4 paper. At the same time, the clip should have good elasticity. Generally, it is good to flick it with your fingers 3-5 times without breaking.

4. If the pen barrel still has a color printing pattern, do a 3M adhesive test (stick the 3M tape to the pattern for at least 1 minute, then tear off the tape at 45°, and the peeling area of the silk screen is less than 5%.

stapler

A. Stapler specifications can be divided into four categories:

8 gauge stapler, 10 gauge stapler, 12 gauge stapler and thick ply stapler.

B. The service life of the stapler is generally 20,000 times.

C. Functions and requirements:

1. The spare parts should cooperate flexibly. When nailing, the nail pusher should move smoothly in the nail path and be able to reset in time. The staple pressing sheet can push the stapler out one by one and bend it in the nail groove, and can successfully drive all the staples in the nail path.

2. The outer surface of the paint film of the stapler should be flat, with basically the same color, no particle impurities, no obvious pinhole bubbles, paint peeling and other phenomena.

3. The surface of the stapler coating should not be blackened, pinholes, yellowing and other defects, and there should be no serious oxidation if it is not the main one.

4. The stapler nail plate and the lower nail groove should be tested for hardness.

Summary of other stationery:

1. Watercolor pens and markers:

① Apply 2KG force to the nib to observe whether the nib is indented.

② Pull the tip of the pen with 1KG force, and observe whether the core of the pen is pulled out within 10 seconds.

2. Combination of whiteboard and magnet: Hit the whiteboard with a force of 1KG to see if the magnet falls off.

3. Crayon: When writing at a 45-degree angle with a force of less than 1.5 kg, observe whether it breaks.

Post time: Dec-14-2022