KEMA-KEUR is a widely recognized safety symbol in the electronic, electrical, and component products industry.

ENEC is a safety certification mark that can replace various EU countries in the European electronic, electrical, and component product industry.

CB is a certificate issued based on the IECEE (International Electrotechnical Commission) standard.

The certification bodies of IECEE member countries test the safety performance of electrical products based on IEC standards, and their test results, namely CB test reports and CB test certificates, are mutually recognized by IECEE member countries.

The purpose of conducting CB testing is to reduce unnecessary testing costs caused by repeated testing. Customers only need to test once to obtain product certificates from CB member country institutions.

What are the main types of plugs and sockets involved?

Main types of household plugs in Europe

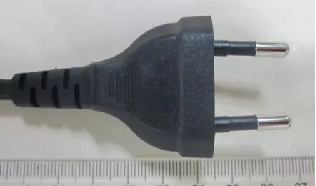

1 European style

(2.5A plug, a universal plug in Europe)

2 German French(Germany, Netherlands, Norway, Sweden, Finland, Denmark, Spain, Austria, Italy, etc)

3 Italy

4 Switzerland

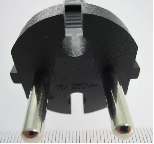

5 British (UK, Ireland)

European standard for testing household plugs

1、The Netherlands - NEN 1020:1987 + A2:2004

2、France - NF C61-314:2017

3、Germany - DIN VDE 0620-2-1:2016 + A1:2017

4、Belgium - NBN C 61-112-1:2017

5、Norway - NEK IEC 60884-1:2002 + A1:2006 + A2:2013 + NEK 502:2016

5、Austria - ÖVE/ÖNORM E 8684-1:2010 + ÖVE/ÖNORM E 8620-3:2012

6、Finland - SFS 5610:2015 + A11:2016

7、Denmark - DS 60884-2-D1:2017

8、Sweden - SS-IEC 60884-1:2013 + SS 4280834:2013

9、Italy - CEI 23-50:2007 + V1:2008 + V2:2011 + V3:2015 + V4:2015

10、Spain - UNE 20315-1-1:2017 + UNE 20315-1-2:2017

11、SEV 1011:2009+A1:2012

12、United Kingdom:BS1363-1:2016+A1:2018

Precautions for European household plugs

1. For non replaceable products, the power cord length has the following requirements:

——The plug comes with a 0.5mm2 power cord, which can only reach a maximum length of 2m

——16A plug with 1.0mm2 power cord, maximum wire length can only reach 2m

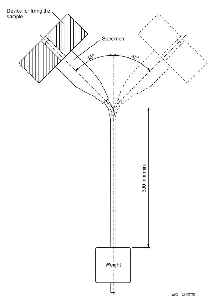

2.Swinging power cord

(1)Completely broken at the bend (possibly at the same location or slightly scattered), or with a breakage rate exceeding the specified limit: this is a common phenomenon, and breakpoints are mostly located at the most vulnerable parts of the structure. If one hand holds the plug and the other pulls the wire, the place with the smallest bending radius is the most likely to break. The locations of the breaks are slightly scattered, often due to the presence of grids at the end of the network, or grids that intersect and are misaligned, so the breaks are not necessarily one point, but multiple points. But usually it's very close!

(2)It broke at the riveting point, which you may not have noticed: this is due to excessive riveting, causing damage to the conductor. However, when bending, the conductor actually expands and contracts in the insulation, resulting in a possible complete or partial breakage at the riveting point without breaking at the bending point. It can be clearly seen through dissection. Attention should be paid to dissection, and the plug should be heated and handled carefully. This situation is also common for manufacturers whose riveting quality is not controlled.

(3)The sheath has slipped out, and the core wire can be seen: this is mainly due to insufficient temperature and pressure during the formation of the plug to fuse the PVC and wire sheath, especially for larger sheaths or rubber sheaths (which cannot be fused at all), so the bonding force between the sheath and the plug is insufficient, resulting in displacement and sliding out when repeatedly bent.

(4)Insulation rupture can reveal the conductor: There are three reasons for this situation: firstly, the insulation ruptures under repeated bending; The second reason is that the PVC at the tail of the plug is broken, and the tear hole continues to extend, tearing the insulation as well; Thirdly, the copper wire breaks and punctures the insulation.

(5)Breakage of plug tail: Poor plug rubber material or poor grid design can cause excessive deformation or stress concentration, leading to the breakage of the tail of the plug!

(6) Conductor piercing insulation and exposure: The bent part of the conductor breaks, causing the insulation to become thinner under stress. The copper wire at the fracture point may protrude from the insulation, and even conductors of different polarities may come into contact, causing an arc.

Testing and Certification Program

1. Required documents before quotation

——Application information (company name and the market in which its products are exported)

——Product name and model, a statement of differences between product models must be provided for series products

——Basic electrical parameters, such as rated current and nameplate identification

——Product structure diagram or pictures, etc

2. Basic information for project proposal

——Documents such as application forms, signed quotations, etc

——Basic information of the product, including BOM material list; Product nameplate; Structural diagrams, etc

——Submit samples

3. Follow up work on the project

——After filing the case, there are dedicated customer service and engineers responsible for it

——Testing and certification

Post time: Sep-04-2024