A life jacket is a type of personal protective equipment (PPE) that keeps a person afloat when falling into the water. Regarding the technical characteristics of life jackets, there are international standards and national regulations. Commonly seen life jackets are foam life jackets and inflatable inflatable life jackets. What are the inspection standards for life jackets? How to inspect the inflatable life jacket?

01 life jacket inspection standard

1. Inspection standard for inflatable life jackets

Export to EU countries - Life jackets must be CE (or ISO) compliant. There are 3 levels of certification, determined by the minimum buoyancy provided by the lifejacket, expressed in Newtons: 100N – for sailing in protected waters or coastal sailing 150N – for offshore sailing 275N – for deep sea sailing and sailing exits in extreme conditions United States – This standard is issued by the United States Coast Guard (USCG). The 2 levels of certification are mainly differentiated based on minimum buoyancy, similar to European standards. Level I: 150N for inflatable life jackets (100N for foam life jackets). Suitable for all types of sailing, including the most difficult conditions. Level II: 100N for inflatable life jackets (70N for foam life jackets). Suitable for inland and confined water sailing.

2. National testing standards for life jackets

GB/T 4303-2008 Marine life jacket GB/T 5869-2010 Life jacket lamp GB/T 32227-2015 Marine life jacket GB/T 32232-2015 Children’s life jacket GB/T 36508-2018 Aviation inflatable life jacket GB 41731-2022 Marine Inflatable life jacket

In all cases, life jackets must meet the current standards for the country of export and the activity in which you are engaged.

On July 13, 2022, the mandatory standard GB 41731-2022 “Marine Inflatable Life Jackets” was released and will be officially implemented on February 1, 2023.

02 Visual inspection requirements for marine inflatable lifejackets

1. The color of marine inflatable life jackets (hereinafter referred to as “life jackets”) should be orange-red, orange-yellow or obvious colors.

2. The life jacket should be able to be worn on both sides without distinction. If it can only be worn on one side, it should be clearly indicated on the life jacket.

3. The life jacket shall have a quick and easy closure to the wearer and fast and correct fastening without knotting.

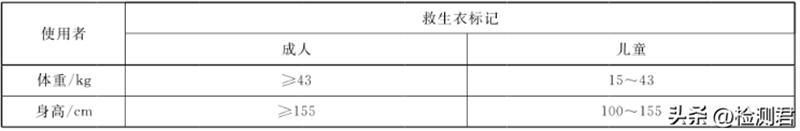

4. The life jacket should be marked with the applicable height and weight range shown in the following table on its obvious part, and the “Children’s Life Jacket” mark should also be marked for the dry children’s life jacket.

5. When the subject is in static equilibrium in the water, the total area of the retroreflective tape attached to the outer surface of the life jacket above the water surface shall not be less than 400cm, and the retroreflective tape shall meet the requirements of IMO Resolution MSC481(102).

6. If the adult life jacket is not designed for persons with a weight greater than 140kg and a chest circumference greater than 1750mm, appropriate accessories should be provided so that the life jacket can be attached to such persons.

7. The lifejacket shall be designed with a throwable buoyant line or other implement so that it can be tied to a lifejacket worn by another person in dry water,

8. The lifejacket shall be designed with a lifting device or attachment for pulling the wearer from the water into the lifeboat/raft or rescue boat.

9. The life jacket should be designed with a life jacket lamp fixture, which should be able to meet the requirements.

10. The life jacket should rely on the inflatable air chamber as buoyancy, and there should be no less than two independent air chambers, and the inflation of any one of the air chambers should not affect the state of the other air chambers. After immersion in water, there should be a lot of dry two independent air chambers automatically inflated, and a manual inflation device should be provided at the same time, and each air chamber can be inflated by mouth.

11. The life jacket should be able to meet the corresponding requirements when any one of the air chambers loses buoyancy.

03 Inspection requirements for marine inflatable life jackets

1 Coated fabrics for inflatable air chambers

1.1 Coating adhesion The average value of dry and wet coating adhesion should not be less than 50N/50mm. 1.2 Tear strength The average tear strength should not be less than 35 N. 1.3 Breaking strength and breaking elongation The average value of dry and wet breaking strength should not be less than 200N, and the breaking elongation should not be greater than 60%. 1.4 Flexural crack resistance After the flexural crack resistance test, there should be no visible cracks or damage. 1.5 Color fastness to rubbing Dry and wet color fastness to rubbing shall not be less than grade 3. 1.6 Color fastness to light The color fastness to light should not be less than grade 5. 1.7 Color fastness to sea water Color fastness to sea water should not be less than grade 4.

2 Strap 2.1 Standard state breaking strength The average breaking strength should not be less than 1600N2.2 The average breaking strength after aging should not be less than 1600N, and should not be less than 60% of the standard state breaking strength.

3 Buckle 3.1 Standard state breaking strength The average breaking strength should not be less than 1600N. 3.2 Breaking strength after aging The average breaking strength shall not be less than 1600N, and shall not be less than 60% of the breaking strength in the standard state. 3.3 Breaking strength after salt spray The average breaking strength shall not be less than 1600N, and shall not be less than 60% of the breaking strength in the standard state.

04 Other inspection requirements for marine inflatable life jackets

1. Whistle - The whistle equipped with the life jacket should be able to make a sound in the air immediately after being immersed in fresh water and taken out. The sound pressure level should reach 100dB(A). – The whistle should be made of non-metallic material, with no burrs on the surface, and can make a sound without relying on any object to move. – The whistle is fastened to the life jacket with a thin cable, and the placement should not affect the performance of the life jacket, and the wearer’s hands should be able to use it. – The strength of the thin cord should meet the requirements of 52 in GB/T322348-2015

2. Temperature cycle After 10 high and low temperature cycles, inspect the lifejacket for appearance. The lifejacket should show no signs of damage, such as shrinkage, cracking, swelling, disintegration, or changes in mechanical properties.

3. Inflatable performance - Automatic and manual inflation systems should be used to inflate immediately after each temperature cycle, and life jackets should be fully inflated. – After being stored in a high temperature environment of 40 °C and a low temperature of -15 °C for 8 hours, the life jackets should be fully inflated by the manual inflation system.

4. After the buoyancy loss lifejacket is immersed in fresh water for 24 hours, its buoyancy loss should not exceed 5%.

5. Burn resistance The life jacket is overfired for 2s. After leaving the flame, check the appearance of the lifejacket. It should not continue to burn for more than 6s or continue to melt.

6. Strength - The strength of the body and the lifting ring: the body and lifting ring of the life jacket should be able to withstand the force of 3200N for 30min without damage, and the life jacket and the lifting ring should be able to withstand the action of 2400N for 30min without damage to the ears. -Shoulder strength: The shoulder of the life jacket should be able to withstand the force of 900N for 30min without damage, and the shoulder of the children’s lifejacket should be able to withstand the force of 700N for 30min without damage.

7. Dressed - Without guidance, 75% of the subjects should put on the life jackets correctly within 1min, and after guidance, 100% of the subjects should put on the lifejackets correctly within 1min. – Under the conditions of provincial weather dress, 100% of the subjects mentioned in 4.91 should put on the life jacket correctly within 1min – The test should be carried out using both inflated and non-inflated life jackets.

8. Water performance - Restoration: After the subject wears the life jacket, the average restoration time should not be greater than the average restoration time plus 1s when wearing the adult reference life jacket (RTD). If there is a “non-flip” situation, the number of “non-flip” should not exceed the number of times when the RTD is worn. The RTD shall meet the requirements in IMO MSC.1/Circ1470 – Static balance: When the subject is in static balance with the selected lifejacket facing upwards, it shall meet the following requirements. a) Clear height: The average clear height of all subjects should not be less than the average clear height when wearing RTD minus 10mmo b) Torso angle: The average trunk angle of all subjects should be no less than the average trunk angle when wearing RTD minus 10mmo Go to 10°-diving and falling into the water: After falling into the water and diving in a standby state wearing a life jacket, the test personnel shall meet the following requirements: a) Keep the test personnel face up, and the clear height of all test personnel from the water surface is not less than 5103 Average clear height when wearing RTD as determined by testing minus 15mm: b) lifejacket does not come off and does not cause injury to test personnel: c) does not affect water performance or breakage of buoyancy cell: d) does not cause lifejacket light to fall off or damaged. – Stability: After the subject is in the water, the life jacket should not sway from side to side so that the subject’s face is out of the water. At least the same number of subjects in the same state as when wearing the RTD. – Swimming and getting out of the water: After swimming for 25m, the number of subjects wearing life jackets who can climb on a life raft or a rigid platform 300mm above the water surface should be no less than 2/3 of the number of subjects without life jackets .

9. Inflatable head load After the inflatable head is subjected to a force of (220±10)N from all directions, there should be no damage. The life jacket should not leak air and remain airtight for 30 minutes.

10. Under pressure The life jacket under normal condition should have no swelling or change in mechanical properties after bearing a load of 75kg, and there should be no air leakage.

11. Pressure performance - Overpressure: The lifejacket should be able to withstand excessive internal pressure at room temperature. It should remain intact and maintain this pressure for 30min.-Release valve: If the lifejacket is equipped with a release valve, it should be able to ensure that the excess pressure is released. The lifejacket shall remain intact and maintain its pressure for 30 minutes, shall show no signs of damage such as rupture, swelling or change in mechanical properties, and shall not visibly damage the inflatable parts. – Air retention: The life jacket inflatable air chamber is filled with air, and placed at room temperature for 12 hours, the pressure drop should not be greater than 10%.

12. Metal parts - Metal parts and components on life jackets should be resistant to seawater corrosion. After the salt spray test in accordance with 5.151, the metal parts shall show no obvious corrosion or influence on other parts of the lifejacket and shall not degrade the performance of the lifejacket. – When the metal parts of the life jacket are placed at a distance of 500mm from the magnetic compass, the influence of the metal parts on the magnetic compass should not exceed 5°.

13. Prevent mis-inflation The life jacket should have the function of preventing accidental inflation. The above are the inspection standards for life jackets exported to the European Union, the United States, the relevant national standards for life jackets, and the material, appearance and on-site inspection requirements for the national marine inflatable inflatable life jackets.

Post time: Oct-21-2022