01 Appearance quality requirements

The appearance quality of track and field sports services mainly includes surface defects, size deviations, size differences and sewing requirements.

Surface defects - color difference

1. Premium products: The same fabrics are greater than 4-5 grades, and the main and auxiliary materials are greater than 4 grades;

2. First-class products: The same fabrics are greater than 4 grades, and the main and auxiliary materials are greater than 3-4 grades;

3. Qualified products: The same fabrics are greater than level 3-4, and the main and auxiliary materials are greater than level 3.

Surface defects - texture distortion, oil stains, etc.

| Defect name | Premium products | First-class products | Qualified products |

| Texture skew (striped products)/% | ≤3.0 | ≤4.0 | ≤5.0 |

| Oil stains, water stains, aurora, creases, stains, | should not | Main parts:

should not be present; Other parts: slightly allowed |

slightly allowed |

| Roving, colored yarn, warp stripes, transverse crotch | 1 needle in 2 places on each side, but it should not be continuous, and the needle should not fall off more than 1cm | ||

| The needle is off the bottom edge | Main parts are less than 0.2cm, other parts are less than 0.4cm | ||

| Open line twists and turns | should not | slightly allowed | Obviously allowed, obviously not allowed |

| Uneven sewing and skewed collar | There should be no chain stitches;

other stitches should not be continuous in 1 stitch or 2 places. |

Chain stitches should not be present; other stitches should be 1 stitch in 3 places or 2 stitches in 1 place | |

| Skip stitch | should not | ||

| Note 1: The main part refers to the upper two-thirds of the front part of the jacket (including the exposed part of the collar). There is no main part in pants;

Note 2: Slight means that it is not obvious intuitively and can only be seen through careful identification; obvious means that it does not affect the overall effect, but the existence of defects can be felt; significant means that it obviously affects the overall effect;Note 3: Chain stitch refers to "Series 100-Chain stitch" in GB/T24118-2009. |

|||

Specification size deviation

The size deviation of the specifications is as follows, in centimeters:

| category | Premium products | First-class products | Qualified products | |

| Longitudinal direction

(shirt length, sleeve length, pants length) |

≥60 | ±1.0 | ±2.0 | ±2.5 |

| <60 | ±1.0 | ±1.5 | ±2.0 | |

| Width direction (bust, waist) | ±1.0 | ±1.5 | ±2.0 | |

Differences in size of symmetrical parts

The size differences of the symmetrical parts are as follows, in centimeters:

| category | Premium products | First-class products | Qualified products |

| ≤5 | ≤0.3 | ≤0.4 | ≤0.5 |

| >5~30 | ≤0.6 | ≤0.8 | ≤1.0 |

| >30 | ≤0.8 | ≤1.0 | ≤1.2 |

sewing requirements

Sewing lines should be straight, flat and firm;

The upper and lower threads should be appropriately tight. The shoulder joints, crotch joints, and seam edges should be reinforced;

When sewing products, sewing threads with strong strength and shrinkage suitable for the fabric should be used (except for decorative threads);

All parts of the ironing should be flat and neat, without yellowing, water stains, shine, etc.

Sampling rules

Determination of sampling quantity: Appearance quality shall be randomly sampled 1% to 3% according to batch variety and color, but shall not be less than 20 pieces.

Determination of appearance quality

Appearance quality is calculated according to variety and color, and the non-conformity rate is calculated. If the rate of non-conforming products is 5% or less, the batch of products will be judged to be qualified; if the rate of non-conforming products is more than 5%, the batch of products will be judged to be unqualified.

Finished product measurement parts and measurement requirements

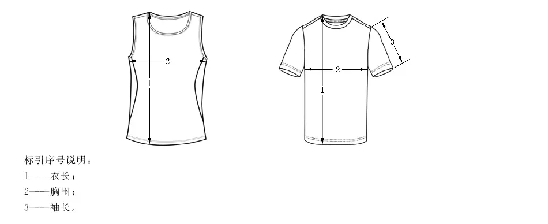

The measurement parts of the top are shown in Figure 1:

Figure 1: Schematic diagram of measuring parts of tops

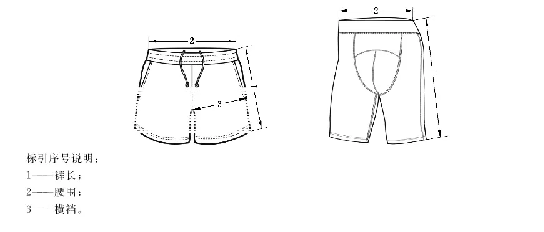

See Figure 2 for the measurement location of the pants:

Figure 2: Schematic diagram of pants measurement parts

The requirements for garment measurement areas are as follows:

| category | parts | Measurement requirements |

| Jacket

|

clothes length | Measure vertically from the top of the shoulder to the bottom edge, or measure vertically from the center of the back collar to the bottom edge |

| chest circumference | Measure horizontally 2cm downward from the lowest point of the armhole seam (calculated around) | |

| Sleeve Length | For flat sleeves, measure from the intersection of the shoulder seam and armhole seam to the edge of the cuff; for raglan style, measure from the middle of the back collar to the edge of the cuff. | |

| Pants | pants length | Measure from the waistline along the side seam of the pants to the hem of the ankle |

| waistline | Midway width of waist (calculated around) | |

| crotch | Measure from the bottom of the crotch to the side of the pants in a direction perpendicular to the length of the pants |

Post time: May-23-2024