As a daily tool for children, the quality of backpacks is not only related to their physical health, but also to their life safety. It is the responsibility and obligation of every quality person to carry out quality inspection and testing of backpacks and safeguard the safety of student supplies.

Keywords of this article: backpack inspection, backpack inspection

01. Inspection standards

The inspection of student backpacks generally adopts the QB/T 2858-2007 “Student Bookbags” standard, which is suitable for placing teaching textbooks, teaching aids, and student supplies, as well as single and double shoulder straps and portable bookbags. In specific inspection and testing, the standard basis available includes: GB/T 2912.1 “Determination of Formaldehyde in Textiles – Part 1: Free Hydrolyzed Formaldehyde (Water Extraction Method)”, GB/T 3920 “Color Fastness Test for Textile Products – Color Fastness to Rubbing”, GB 6675-2003 “National Toy Safety Technical Specification”, GB 21207-2007 “General Safety Requirements for Student Supplies” QB/T 3826 “Corrosion resistance test method for metal coatings and chemically treated coatings of light industrial products – Neutral salt spray test (NSS) method”, QB/T 3832 “Evaluation of corrosion test results for metal coatings of light industrial products”, etc.

02. Inspection points and methods

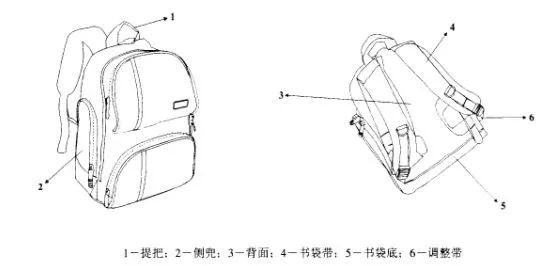

The key indicators for quality inspection of student backpacks include weight bearing, deformation, stitching strength, color fastness to friction, accessory safety, and formaldehyde content of fabric accessories. In addition, attention should be paid to the comfort of the back when using the backpack, as well as the ease of use of the backpack straps and handles.

In addition to referring to the inspection of luggage, there are several points to pay special attention to in the inspection of backpacks. The requirements are slightly different: appearance requirements – the appearance quality of the backpack should comply with the following regulations: overall appearance, full shape, clear lines, flat and smooth adhesion, upright, and overall cleanliness. Zipper, with consistent edge spacing, straight stitching, no missing or missing teeth, and smooth pulling and closing. Accessories and installation should have a smooth surface, bright and free of rust residue, missed plating, needle holes, blistering, peeling, and detachment. The accessories should be installed firmly. Suture lines should be suitable for the quality of the fabric and lining used, with quality and color matching each part. The fabric should have no broken warp or weft, and should not skip threads, threads, marks, stains, or blemishes. The printing appearance requires clear patterns, bright colors, correct overprinting, no flowing or exposed ink, and no color fading. Suture stitches should match the upper and lower threads, with straight stitches and consistent needle spacing. Empty stitches or skipped stitches are not allowed on the front large surface and front cover of the book bag. No skewed stitching exceeding 12mm in length is allowed. A single product should have no more than one empty needle or missing needle, and no more than two empty needles, missing needles, or skipped needles.

Load bearing test – The load bearing test for student backpacks requires that the handles, straps, adjustment straps, and hooks should not fall off or break under the specified load, and the bag body should not crack.

The weight requirements are as follows:

Serial Number Specification (height)/mm Load/kg1 < 30032300-400 (excluding 400) 53400-50074 > 50010

Swing test – The backpack is loaded according to regulations, and the straps and handles are tested separately: hang in the air, the straps are in the longest state, or adjust the distance from the swing axis to 50cm-60cm, swing 30 times (forward and backward as 1 time), and the swing angle is (60 ± 3) °. After the swing stops, check whether the backpack straps, handles, adjustment straps, and hooks are secure. Measure whether the deformation of the connecting component exceeds 20% compared to the original length within 2 minutes. Static and drop test – Measure the length of the components that serve as links on the backpack. The backpack should be loaded 1.2 times the specified weight, suspended in the air (with the strap in the longest state), and the bottom of the backpack should be 60cm above the ground (with a hard wooden surface), so that it is evenly stressed and in a static and upright state. After 30 minutes, drop vertically and check if the straps, handles, adjustment straps, and shackles are secure. Measure the length of the straps, handles, adjustment straps, and shackles that serve as connections within 2 minutes, and check if the deformation exceeds 20% compared to the original length.

Post time: May-15-2023