The four-point scale is the main scoring method for fabric inspection, and it is the necessary knowledge and skills for QC in the textile industry.

Keywords in this article: fabric inspection four-point system

01

What is the four-point system?

A four-point scale can be used for woven knitted fabrics, with 1-4 points deducted depending on the size and severity of the defect

Calculation method: single roll score = deduction score / code length * 100

Average scoring method = total deduction points / total code length * 100

Acceptance range: A grade below 50 points per 100 straight-line yards, B grade above 50 points

Calculation method: After each roll of cloth is inspected, you can add up the scores obtained, and use the following formula to calculate the score of each roll of cloth per 100 square yards

The number of points per 100 square yards of a single roll of fabric = deduction points * 3600 / (inspected yards * effective door width inches)

The average score of 100 square yards = (total deduction points * 3600) / (total inspected yards * average effective door width inches) The calculation result is accurate to one decimal place.

Acceptance range: A single roll with less than 40 points per 100 square yards is grade A, and more than 40 points is grade B. The average score of all inspected fabrics is less than 28 points per 100 square yards. The above conditions must be met at the same time, even if a single roll is less than every 40 points per 100 square yards, but all inspection fabrics are still more than 28 points per 100 square yards, the conclusion is also judged as unqualified. Different fabrics can have different requirements for qualifying scores, and qualifying scores can also be specified by the buyer and supplier after agreement.

02

Principles of use of the four-point scale

· The deduction of all warp and weft defects shall not exceed 4 points;

· 4 points per yard for continuous/cyclic defects (>9inches);

· 4 points will be deducted for holes, narrow pieces, seams and other full-width defects;

· For serious defects, each yard of defects will be rated 4 points, such as all holes will be rated 4 points regardless of diameter, and any holes larger than pinholes will be deducted 4 points;

· For continuous defects, such as: rungs, edge-to-edge chromatic aberration, narrow or irregular fabric widths, creases, uneven dyeing of fabrics, 4 points shall be deducted per yard of defects;

· For fabrics with a width greater than 64-66 inches, the deduction of each yard in the straight yard score can be increased by more than 4 points proportionally;

· Defects within one inch of the edge on both sides will not be scored except for damage;

The length of the defect is calculated according to the maximum direction of warp or weft. When two or more defects are mixed together, the unit of the largest defect is calculated;

· Unless otherwise specified, usually only the front side of the cloth needs to be inspected. For plain weave fabrics, the shift printing side is the front side. For twill fabrics, the left bias is positive. For thread fabrics, the right unloading is positive. For satin fabrics, the satin side is positive. The composite fabric should be confirmed with the guest in advance. Don’t confuse pros and cons. If there are defects on the reverse side of the fabric that affect the positive effect, the degree of influence is scored;

· For defects with intermittent or small scattered distances, if the respective measurement scores are greater than the total measurement scores, the total measurement score shall be calculated;

· Calculation method of strips: one or the weft (warp) direction defect of the machine, the width is less than one centimeter, and each centimeter is more than one centimeter. One centimeter is counted as one.

03

Sampling

Sampling inspection, 100% of the goods must have been completed, 80% of the packaged, taken from the actual packing list or code list from the factory or supplier.

Number of samples:

· 10%, 20% of the delivery quantity;

· Or take the square root of the number of shipments and multiply by 10;

· When the delivery quantity is less than 1000 yards, full inspection.

04

Testing method

· The inspection distance is about 1 yard, and the light source requirements: the surface illuminance is at least 1075 lux, and the installation is parallel to the cloth surface.

· Suggestion:

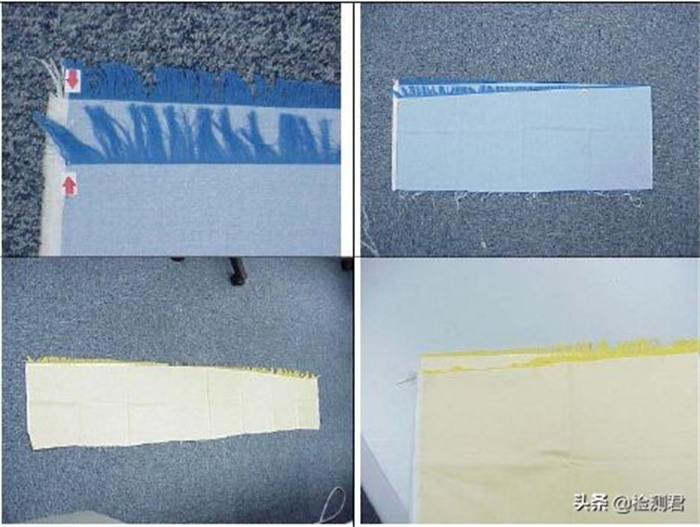

light-colored or thin cloth, add a piece of cloth between the cloth and the cloth inspection inclined plate before inspection.

· Visual inspection inspection scope: fabric defects such as weaving dyeing and printing, general appearance structure and materials, etc., color, width, roll length, weft bow and weft skew, packaging and marking.

· Appearance can be based on the customer’s reference sample, mainly check the style, pattern and effect to check the printed jacquard pattern for at least one cycle.

· Structure:

If the customer needs, you can sample to test the fiber composition, yarn type, yarn count.

·Material hand feel:

Check whether the hand of the cloth is hard or soft, thick or thin by comparison. If there is a relatively obvious difference, it should be noted on the report and recorded in the material column as discrepancies, and samples of different hand feel should be taken. If possible Samples can compare the hand feel of different rolls of the same batch.

05

Checking point

· Roll length and width

If the difference between the actual length of a single roll and the length of the label is greater than 2%, the single roll is reduced to a second-class product;

If the sum of the total length of all inspected rolls is less than 1% of the nominal total length, it should be reported, and the whole batch may be downgraded;

Measure the effective door width 3 times at the head, middle and tail respectively. Generally, customers do not accept narrow width, and the width of weft elastic fabric is less than 2%.

· Weft oblique and bow weft

Cut the cloth along the weft direction, as far as possible close to the direction of the weft bending;

Remove the weft yarns one by one;

until a complete weft is drawn;

Fold in half along the warp, with the edges flush, and measure the distance between the highest point and the lowest point.

Fabric weight

Weigh at least two samples from different coils for each inspection:

· <10OZ/SQ.YD: +/-5%;

· >10OZ/SQ.YD: +/-3%.

Fabric packaging precautions

· Appropriate thickness and strength of the paper tube;

· The inner diameter of the paper barrel;

· Length of paper barrel;

· Avoid too loose and too tight

Post time: Aug-14-2022