This is a safety helmet sold in our labor protection market, with prices ranging from 3-15 yuan. Does it meet the requirements of safety helmet quality and performance? GB2811-2019 Head protection helmets require that ordinary helmets undergo impact absorption, puncture resistance, and chin strap strength tests and meet the requirements.

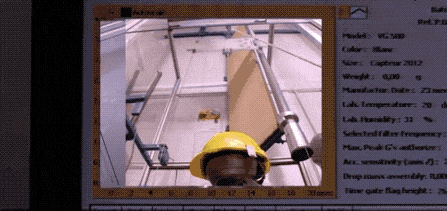

Using a 5kg drop hammer, impact the safety helmet from a height of 1 meter, and the force transmitted to the head mold should not exceed 4900N. There should be no fragments falling off the helmet shell. The hammer head is hemispherical, with a radius of 48mm, made of 45 # steel, and has a symmetrical and uniform shape. Why cannot it exceed 4900N?

4900N (Newton) is the unit of force, which is equivalent to approximately 500 kilograms of force (kgf).

The magnitude of this force is quite large, and if it is directly applied to a person's head, it may cause serious injury. According to the search results, the design standard for safety helmets requires that they should not be damaged under an impact force of 4900N to protect the head from injury.

This is because the maximum force on the human cervical spine is 4900N, and exceeding this force value may lead to cervical spine injury or other serious consequences. Without the protection of a safety helmet, if a force of 4900N is directly applied to a person's head, it may cause skull fractures, concussion, or even more serious brain damage, endangering life.

Therefore, safety helmets are very important personal protective equipment in the work environment, especially in situations where there is a risk of falling objects.

To better understand the magnitude of the force of 4900N, it can be compared by converting the units of force. For example, 1 Newton is approximately equal to 0.102 kilogram force.

So 4900N is equivalent to approximately 500 kilograms of force, which is equivalent to the gravity of a half ton (500 kilograms) object.

In summary, 4900N is a very large force that, if applied directly to a person's head, could cause fatal injuries. That's also why safety helmets need to have strict standards to ensure that they can protect the wearer's safety when subjected to such impact forces.

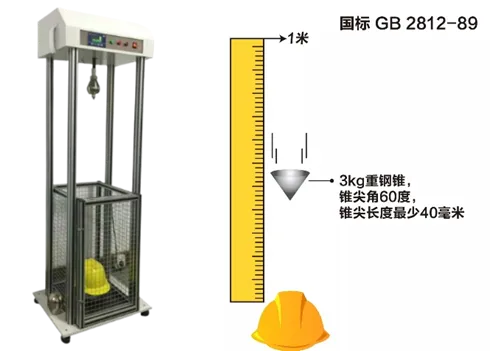

Use a steel hammer weighing 3kg to freely drop and puncture the safety helmet from a height of 1 meter. The steel cone must not touch the surface of the head mold, and the cap shell must not have any fragments falling off. The steel cone is made of 45 # steel and weighs 3kg. The puncture part has a cone angle of 60 °, a cone tip radius of 0.5mm, a length of 40mm, a maximum diameter of 28mm, and a hardness of HRC45.

The force value when the chin strap is damaged in the dynamic diagram of the impact absorption and puncture resistance test should be between 150N and 250N. Special safety helmets also require special performance requirements: lateral rigidity

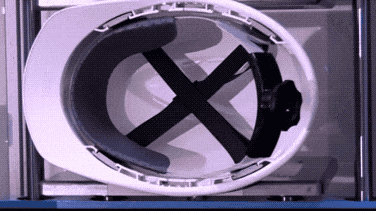

Place the safety helmet on the side between two flat plates, with the brim outside and as close to the plate as possible: the testing machine applies pressure to the safety helmet through the plate, and the maximum deformation should not exceed 40mm, residual deformation should not exceed 15mm, and there should be no debris falling off the helmet shell.

The industrial methane flame jet nozzle stably sprays a blue flame with a length of 50mm. The flame acts on the cap shell for 10 seconds and the ignition time should not exceed 5 seconds. The cap shell should not burn through.

In addition, there are requirements for low temperature resistance, extreme high temperature resistance, electrical insulation performance, anti-static performance, and resistance to molten metal splashing

Post time: Aug-21-2024