If there is a country where carbon neutrality is a matter of life and death, it is the Maldives. If sea levels rise just a few inches more, the island nation will sink under the sea. It plans to build a future zero-carbon city, Masdar City, in the desert 11 miles southeast of the city, using the abundant solar energy in the desert to build the largest 10-megawatt solar farm in the Middle East.

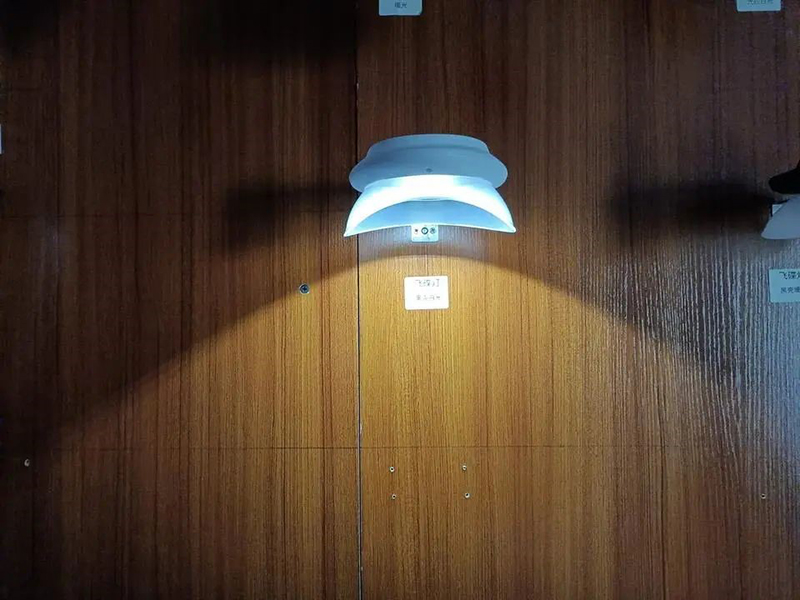

Umbrella-shaped solar panels in Masdar City collect sunlight during the day night it folds into a street light

As ecological problems brought about by global temperature changes become increasingly apparent, glaciers melt, sea levels rise, flooding coastal countries and lowland areas, and extreme weather continues to occur… These are all caused by excessive carbon emissions, and carbon reduction actions are imperative. .

The United States, the European Union, the Nordic countries Finland, Sweden, Norway, Denmark and Iceland, Brazil, Canada, Switzerland, Germany, Russia, India and other countries have stated that they will work together to increase their efforts to combat climate change and strive to achieve “carbon neutrality” faster. Target. During the two sessions in 2021, the National Energy Administration proposed to formulate more aggressive new energy development goals and accelerate the promotion of carbon peaking and carbon neutrality. The application of solar photovoltaic new energy is an important means to reduce carbon emissions. Solar lights use solar energy as the source of energy. They absorb light energy during the day and store it in the battery. At night, they convert the light energy into electrical energy for power generation. As a safe and environmentally friendly new electric light, solar lights are receiving more and more attention.

The following is the inspection method for solar lights:

1. Sampling is carried out in accordance with ANSI/ASQ Z1.4 Single Sampling Plan.

2. Solar lamp appearance and process inspection The appearance and process inspection of solar lamps are the same as the inspection of other types of lamps. The style, material, color, packaging, logo, label, etc. of the solar lamp are inspected.

1. Solar lamp data testing and on-site testing

1). Transportation drop test: Perform a drop test in accordance with ISTA 1A standard. After 10 drops, the solar lamp product and packaging should have no fatal or serious problems.

2) . Solar lamp weight measurement: Based on the solar lamp specifications and approved samples, if the customer does not provide detailed tolerances or tolerance requirements, a tolerance of +/-3% shall be applied.

3) . Barcode scanning verification: The barcode on the solar lamp housing can be scanned, and the scanning result is correct.

4) . Assembly and installation inspection: The solar lights can be assembled normally according to the instructions and there should be no problems.

5) . Start-up inspection: The solar lamp sample is powered by the rated voltage and works at full load for at least 4 hours or according to the instructions (if less than 4 hours). After the test, the solar lamp sample should be able to pass the high voltage test, function, grounding resistance test, etc. , there should be no defects in the final test.

6) .Power consumption check or input power/current inspection: The power consumption/input power/current of solar lights should comply with product specifications and safety standards.

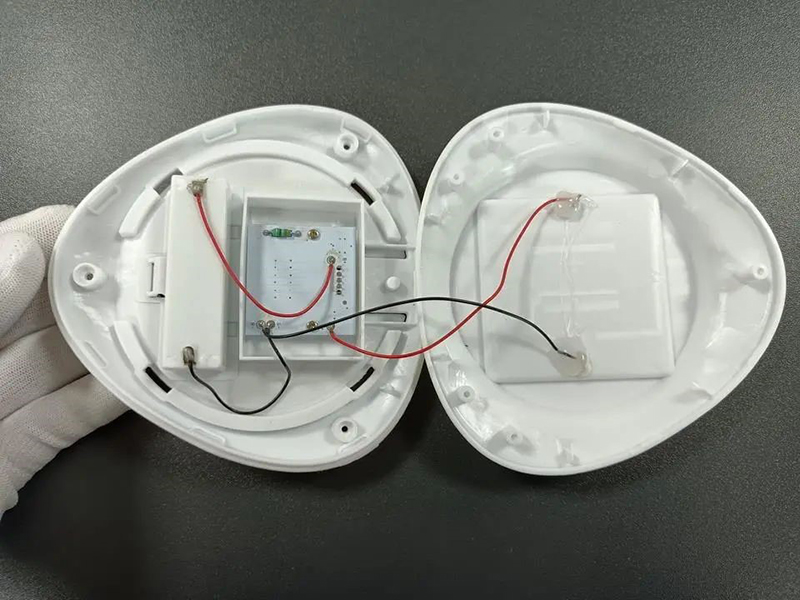

7) . Inspection of internal workmanship and key components: Check the internal structure and components of the solar lamp. The lines should not touch sharp edges, heating parts, and moving parts to avoid insulation damage. The internal connections of solar lights should be fixed, and the CDF or CCL components should meet the requirements.

8) . Friction test of the rated label and adhesion test of the printed label: Wipe the 15S solar light rated sticker with a cloth dipped in water, and then wipe the 15S solar light with a cloth dipped in gasoline. There will be a bad reaction.

9) . Stability test (applicable to portable vertical products): The product (except fixed appliances and hand-held appliances) is placed on a surface at 6 degrees (Europe) / 8 degrees (U.S. market) with the horizontal surface according to normal use (such as toys or outdoor For portable lights, use an inclined surface of 15 degrees), the power cord should be placed in the most unfavorable position, and the solar light should not tip over.

10) . Charge and discharge inspection (solar cells, rechargeable batteries): Charge and discharge according to the declared requirements, and they should meet the requirements.

11) . Waterproof test: IP55 water-proof, the solar lamp will not affect its functionality after being sprayed with water for two hours.

12). Battery voltage inspection: rated voltage 1.2v.

Post time: Oct-20-2023