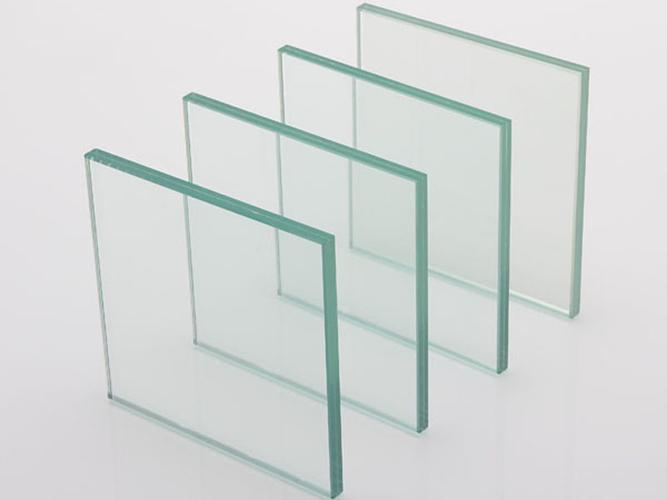

Tempered glass is glass with compressive stress on its surface. Also known as reinforced glass. Using tempering method to reinforce glass.

Tempered glass belongs to safety glass. Tempered glass is actually a type of prestressed glass. In order to improve the strength of glass, chemical or physical methods are usually used to form compressive stress on the surface of the glass. When the glass is subjected to external forces, it first offsets the surface stress, thereby improving its load-bearing capacity, enhancing its own wind pressure resistance, cold and heat resistance, impact resistance, etc. Pay attention to distinguishing it from fiberglass.

Characteristics of tempered glass:

Security

When glass is damaged by external forces, the fragments will form small blunt angle particles resembling honeycomb shapes, which are less likely to cause serious harm to the human body.

high strength

The impact strength of tempered glass with the same thickness is 3-5 times that of ordinary glass, and the bending strength is 3-5 times that of ordinary glass.

thermal stability

Tempered glass has good thermal stability, can withstand three times the temperature difference of ordinary glass, and can withstand temperature changes of 300 ℃.

Advantage

The first is that the strength is several times higher than ordinary glass, and it is resistant to bending.

The second is safety in use, as its load-bearing capacity increases and improves its fragility. Even if tempered glass is damaged, it appears as small shards without sharp angles, greatly reducing harm to the human body. The resistance of tempered glass to rapid cooling and heating is 3-5 times higher than that of ordinary glass, and it can generally withstand temperature differences of more than 250 degrees, which has a significant effect on preventing thermal cracking. It is a type of safety glass. To ensure the safety of qualified materials for high-rise buildings.

Shortcoming

Disadvantages of tempered glass:

1.Tempered glass cannot be further cut or processed, and can only be processed to the desired shape before tempering.

2.Although tempered glass has stronger strength than ordinary glass, it has the possibility of self explosion (self rupture), while ordinary glass does not have the possibility of self explosion.

3.The surface of tempered glass may have unevenness (wind spots) and slight thinning of thickness. The reason for thinning is that after the glass is softened by hot melting, it is rapidly cooled by strong wind, causing the crystal gaps inside the glass to decrease and the pressure to increase. Therefore, the glass is thinner after tempering than before. Generally, 4-6mm glass becomes 0.2-0.8mm thinner after tempering, while 8-20mm glass becomes 0.9-1.8mm thinner after tempering. The specific degree depends on the equipment, which is also the reason why tempered glass cannot have a mirror finish.

4.The flat glass used in construction after physical tempering in a tempering furnace generally undergoes deformation, and the degree of deformation is determined by the equipment and technical personnel's process. To a certain extent, it affects the decorative effect (except for special needs).

Testing items for tempered glass

1. Appearance inspection

Appearance inspection is the first process of quality inspection for tempered glass, which mainly involves inspecting the surface of the glass, including observing for defects such as cracks, bubbles, and scratches.

2. Bending strength test

Bending strength is one of the main performance indicators of tempered glass and an important parameter for evaluating glass strength. The bending strength test usually adopts the four point bending method, which applies force to the glass plate and observes its fracture situation to obtain the bending strength value.

3. Fragmentation mode detection

Tempered glass exhibits obvious fragmentation patterns after fracture, mainly divided into radial fragmentation and fracture modes. The detection method usually uses microscopic observation to evaluate its fragmentation mode.

4. Optical performance testing of tempered glass

The optical properties of tempered glass are of great significance for its applications. The optical performance indicators of tempered glass include transmittance, diffuse reflectance coefficient, color difference, etc. The detection method usually uses a spectrophotometer or colorimetric meter for testing.

5. Quality inspection of heat treatment

For heat-treated tempered glass, temperature and time are the main factors affecting its performance. Therefore, for the quality of heat treatment, it is necessary to detect parameters such as surface stress, bending, and cracks on the glass.

Post time: Jul-12-2024