The weight of the fabric is an important technical indicator for knitted and woven fabrics, and it is also a basic requirement for textile and clothing inspection.

1.What is grammage

The "grammage" of textiles refers to the weight unit measured in grams under a standard unit of measurement. The weight of a fabric is generally measured in grams per square meter. For example, the weight of a knitted fabric of 1 square meter is 200 grams, expressed as 200g/m ² or 200gsm, etc.

The higher the weight of the fabric under the same composition conditions, the more expensive it is; The lower the weight of the fabric, the cheaper the price. Weight is an important technical indicator for textile fabrics, such as sweatshirts, looped fabrics, PU fabrics, etc.

2.Weight analyzer

The weight gauge, also known as the textile fabric weight gauge, is mainly used in industries such as textile fabrics and leather to inspect the weight of products per unit area. The weight analyzer is suitable for cutting circular samples of various fabrics such as wool, cotton, synthetic, knitted, etc.

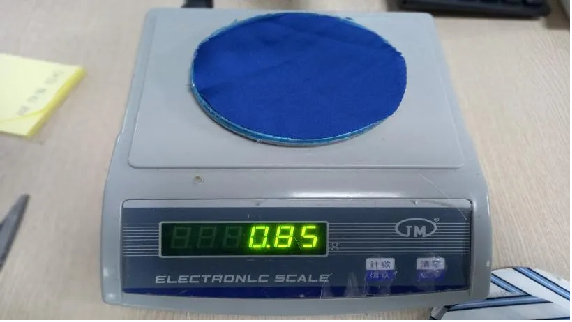

Lay the fabric to be inspected flat on a dedicated rubber pad, place the disc sampler on the fabric, place the sampling knife on the fabric, and then pull out the safety switch of the sampling knife. At this time, hold the protective seat of the sampling knife with your left hand and rotate the circular handle of the sampling knife clockwise with your right hand, making a circle. The sampling is complete. Return the sampling knife switch to its original position. Place the cut sample into a grammage electronic balance, weigh the sample, multiply by 100 times, and obtain the grammage of 1 square meter of the sample. For example, if the weight data of the sample taken is 1.28 grams, then 1 square is 128 grams.

3.Weight example

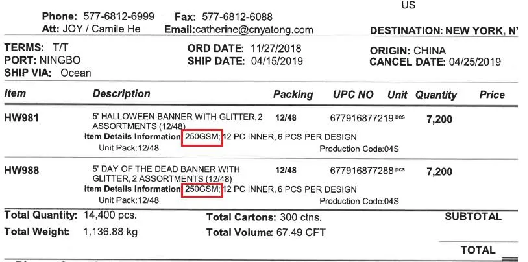

When inspecting goods, if similar words are found in the inspection data, it is necessary to consciously check whether these data meet the requirements, which are usually important data.

When inspecting goods, if the factory can provide tools for engraving unit circles, the following method should be used to check the data. If the factory cannot provide engraving plates but can provide accurate electronic scales, the inspector can also use a ruler or scissors to cut the product into a 10X10cm positive shape and directly place it on the electronic scale to obtain the weight value.

1. Calculation of textile fabric weight

(1) Weight per square meter: commonly used for calculating knitted fabrics, such as 220g/M, which means that the fabric weighs 220 grams per square meter.

(2) Oz/square meter: This notation is commonly used for woven fabrics such as woolen and denim fabrics.

(3) Mm/m ²: Typically used to express the weight of silk fabrics.

Common conversion: 1 ounce=28.350 grams

And generally, woven fabrics are expressed in terms of warp and weft density to indicate weight.

2. Weight calculation of silk fabric: expressed in (m/m).

The conversion method is as follows:

The conversion constant between 1 square meter of weight and 1 meter of weight: fabric width of 1 inch, length of 25 yards, weight of 2/3, daily cost of 1m/m, equivalent to metric system: 1 inch=0.0254 meters, 1 yard=0.9144 meters, daily cost of 3.75 grams

Area: 1 inch x 25 size=0.0254X0.9144X25=0.58064 square meters

Weight: 2/3 daily cost=2.5 grams

1 millimeter (m/m)=2.5/0.58064=4.3056 grams per square meter, conversion constant=4.3056

Square meter weight converted to meters: meters (m/m)=square meter weight/4.3056

The minimum value of Mumi is taken as 0.5m/m, and one decimal place is retained during calculation (rounded to the second decimal place).

Post time: Sep-14-2024