We know that hyaluronic acid, as a beauty product, has moisturizing and moisturizing effects and is widely used in various skin care products such as facial mask, face cream and moisturizers. With the development of science and technology and the improvement of living standards, people’s pursuit of clothing is not only beautiful and warm, but also comfortable, environmentally friendly and healthy. As a functional textile with additional value, it is more and more popular. When hyaluronic acid encounters textiles, what sparks will it produce?

What is hyaluronic acid and what is its effect?

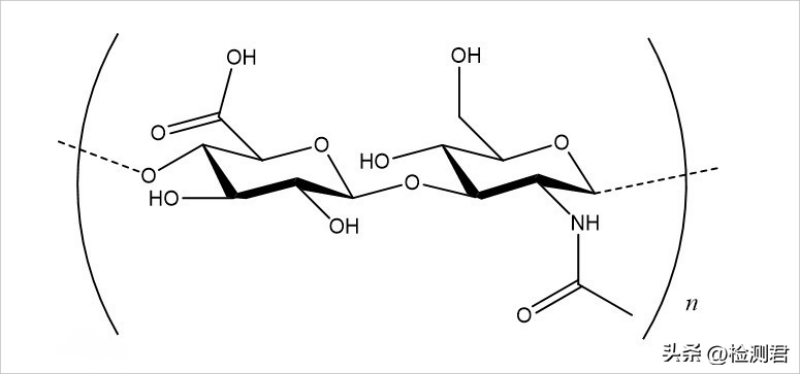

Hyaluronic acid, also known as hyaluronic acid, is a large polysaccharide composed of two disaccharide units, D-glucuronic acid and N-acetylglucosamine. Hyaluronic acid is an important component of connective tissue such as human intercellular substance, vitreous body, joint synovial fluid, and plays an important physiological role in maintaining water, maintaining extracellular space, regulating osmotic pressure, lubricating, and promoting cell repair.

What is hyaluronic acid textiles? What are its benefits?

Hyaluronic acid textiles refer to the textiles containing hyaluronic acid by attaching hyaluronic acid molecules to the fibers through the post-finishing process. Compared with cosmetics, the contact time between textiles and human body is longer and the contact area is large. Hyaluronic acid, a functional component added in the fabric, can achieve skin health care to a greater extent. Therefore, Hyaluronic acid textiles are popular with consumers. Hyaluronic acid molecule contains a large number of hydroxyl groups and other polar groups, which can form a continuous three-dimensional honeycomb network structure at a low concentration, making Hyaluronic acid, like a “molecular sponge”, can absorb and maintain 1000 times its own weight of water, thus making the fabric soft and comfortable, and keeping the skin moist and not dry. Hyaluronic acid is internationally recognized as the best humectant, with the laudatory name of “natural moisturizing factor”, and it is also a glycosaminoglycan, which has no species specificity, good compatibility, and will not cause allergic reactions and safety problems.

How are hyaluronic acid textiles produced and processed?

At present, there are four main preparation methods of fabrics containing hyaluronic acid: dip rolling method, microcapsule method, coating method and fiber method. Dipping method is a kind of processing method that uses the finishing agent containing hyaluronic acid to treat the fabric by dipping method. This method is simple, convenient and efficient, and is widely used at present. Microcapsule method is a method that uses film-forming materials to wrap hyaluronic acid in microcapsules, and then fix the microcapsules on the fabric fibers. This method can obtain fabrics with lasting moisture retention. The coating method usually deposits hyaluronic acid on the fiber surface through electrostatic self-assembly technology, which is more complex and less applied. The fiber method is a method of adding hyaluronic acid into the spinning stock solution and then spinning. This method can obtain hyaluronic acid textiles with higher durability, and is also the direction of large-scale processing of hyaluronic acid textiles in the future.

How to identify whether there is hyaluronic acid in textiles?

Generally, textiles containing hyaluronic acid cannot be distinguished by visual observation, and it is also difficult to distinguish by hand feeling method. Therefore, it is necessary to analyze whether the textiles contain natural moisturizing factor hyaluronic acid with the help of precision instruments. At present, there are three main methods to detect the content of hyaluronic acid: colorimetry, volume exclusion high performance liquid chromatography and high performance liquid chromatography. The colorimetric method has poor specificity and is easy to be disturbed, which may lead to inaccurate test results and false positive results. The volume exclusion high performance liquid chromatography usually has a high detection limit, which is applicable to cosmetics with high content of hyaluronic acid, but not to textiles with relatively low content. High performance liquid chromatography is currently divided into acidolysis – precolumn derivatization-high performance liquid chromatography and enzymolysis – high performance liquid chromatography. Among them, acidolysis – precolumn derivatization-test operation steps are cumbersome, and the reproducibility of test results needs to be improved, so this method is less applied; Due to the good specificity of the enzyme and the single enzymolysis product, the enzymolysis has strong specificity and high accuracy, and has been gradually applied to the analysis of hyaluronic acid content in complex samples.

Post time: Mar-17-2023