National mandatory standards uye IEC vanezvinodiwa zvehunyanzviyemaka, anti-shock dziviriro, chimiro, mashandiro emagetsi, mashandiro emuchina, nezvimwe zvemapulagi uye zvigadziko zveimba uye zvakafanana zvinangwa. Izvi zvinotevera zviyero zvekuongorora uye nzira dzemapulagi uye zvigadziko.

1. Kuongororwa kwekuonekwa

2. Dimensional kuongorora

3. Kudzivirirwa kubva kumagetsi

4. Kudzika matanho

5. Terminals uye Headers

6. Chimiro chesoketi

7. Kuchembera-kusagadzikana uye hunyoro-uchapupu

8. Insulation resistance uye simba remagetsi

9. Tembiricha inokwira

10. Kuputsa simba

11. Normal kushanda (upenyu bvunzo)

12. Kudhonza-kunze simba

13. Mechanical simba

14. Heat resistance test

15. Zvisungo, zvikamu zvinotakura zvino uye zvinobatanidza

16. Creepage kureba, magetsi clearance, penetration insulation sealing distance

17. Kusagadzikana kwekupisa kwekupisa uye kupisa kwemoto kwezvinhu zvinodzivirira

18. Anti-ngura kuita

1. Kuongororwa kwekuonekwa

1.1 Izvo zvakakosha zvechigadzirwa zvinofanirwa kuve neanotevera mamaki:

- Yakatemerwa ikozvino (amps)

- Yakatemerwa voltage (volts)

- Simba rekupa chiratidzo;

-Zita, trademark kana chitupa chiratidzo chemugadziri kana mutengesi;

-Chigadzirwa nhamba

-Chitupa chiratidzo

1.2 Iwo chaiwo zviratidzo zvinofanirwa kushandiswa pachigadzirwa:

1.3 Kune zvigadziko zvakagadziriswa, zvinotevera zvinocherechedzwa zvinofanirwa kumakwa pazvinhu zvikuru:

- Yakatemerwa ikozvino, yakayerwa voltage uye magetsi ekupa zvivakwa;

-Zita kana mucherechedzo kana chiratidzo chemugadziri kana mutengesi;

-Kureba kwekuvharidzira kunofanirwa kubviswa mutyairi asati apinzwa mune screwless terminal (kana iripo);

- Kana iyo socket yakakodzera chete yekubatanidza tambo dzakaoma, panofanira kuva nechiratidzo chokuti screwless terminal inokodzera chete kubatanidza tambo dzakaoma;

-Model nhamba, iyo inogona kuva nhamba yekarodha.

1.4 Kutaridzika kwehutano: Kumusoro kwechigadziko kunofanira kuva kwakatsetseka, ganda rinofanira kunge rakafanana, uye hapafaniri kuva nemapores, kuputika, indentations, kuputika, kukanganisa, mavara, kana tsvina; zvikamu zvesimbi hazvifanirwe kunge zvisina oxidation, ngura mavara, deformation, tsvina, uye kupfeka kunofanirwa kuve kwakafanana uye kwakajeka.

1.5 Packaging: Iro zita rechigadzirwa, zvirevo, kodhi yezvinhu, zita refekitori, huwandu, uye nhamba yekugadzira batch inofanira kunyorwa pabhokisi rekurongedza.

2. Dimensional kuongorora

2.1 Socket inofanira kuiswa nekubuditswa ka10 neplug ine hombe yepini saizi inoenderana nezvinodiwa zvechiyero chinoenderana. Ukuru hwepini hunotariswa nekuyera kana kushandisa geji.

2.2 Mune yakapihwa sisitimu, plug haifanire kusangana neanotevera socket-outlets:

-Sockets ine yakakwirira voltage ratings kana yakaderera ikozvino ratings;

-Sockets ane nhamba yakasiyana ye electrode;

3.1 Kana plug yanyatsopinzwa musocket, zvikamu zvipenyu zveplug zvinofanirwa kunge zvisingasvikike. Tarisa kuti inokodzera here nekuongorora. Fixed socket-outlets, mated plugs uye anotakurika socket-outlets anozovakwa uye akagadzirwa zvekuti, kana akaiswa kana wayamwa kuti ashandiswe zvakajairika, zvikamu zvehupenyu hazvisvikike kunyangwe mushure mekubviswa kwezvikamu izvo zvinosvikika pasina maturusi. Izvo zvakafanana zvinoenda kune zvikamu zvinogona kubviswa.

3.2 Kana zvigadzirwa zvemagetsi zvave newaya uye kuiswa zvinoenderana nezvinodiwa zvekushandisa zvakajairwa, zvichiri kusvikika zvikamu, kunze kwezvimedu zvidiki uye zvikamu zvakafanana zvinoshandiswa kugadzirisa zvikamu zvikuru uye zvivharo uye zvivharo zvezvigadziko, izvo zvakaparadzaniswa kubva kune mhenyu. zvikamu. Dzinofanirwa kugadzirwa nezvinhu zvekudzivirira. zvinhu.

3.3 Chero pini yeplug haizokwanisa kubatana nelive socket yesocket kana chero ipini iri pakusvikika.

3.4 Zvikamu zvekunze zvepuragi zvichagadzirwa ne insulating material. Izvi hazvibatanidzi zvikamu zvinosvikika zvakaita semasiruuru egungano, mapini anotakura ikozvino, mapini ekudzika, masimbi ekudzika, uye mhete dzesimbi dzakatenderedza mapini.

3.5 Socket ine gonhi rekudzivirira, kana ipuragi yaburitswa kunze, socket mhenyu inogona kuchengetedzwa otomatiki.

3.6 Sleeve yepasi pesoketi haifanirwe kukanganiswa nenzira inoisa njodzi nekuda kwekuiswa kweplug.

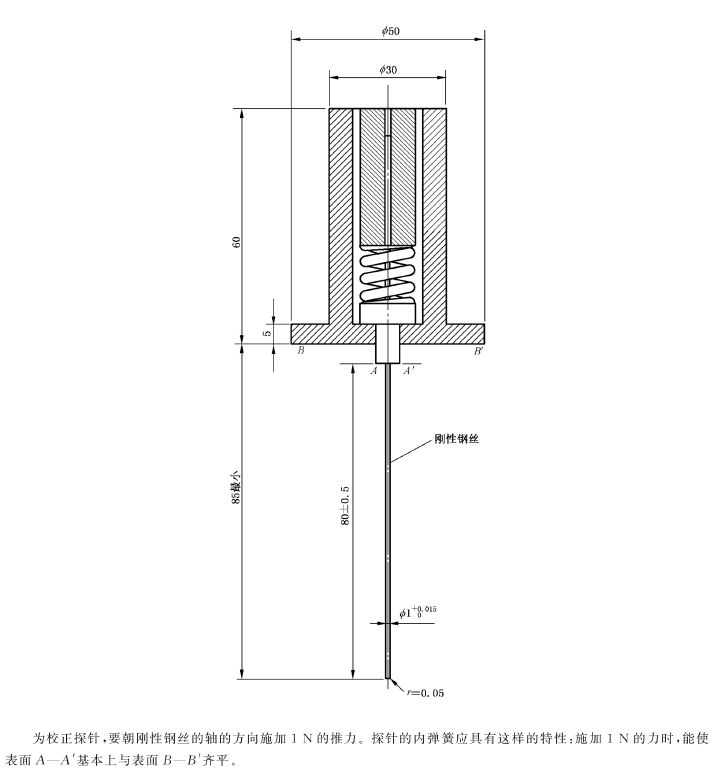

3.7 Kune zvigadziko zvine dziviriro yakawedzerwa, kana yaiswa uye newaya zvinoenderana neyakajairwa kushandiswa zvinodiwa, mhenyu dzinofanirwa kunge dzisingasvikike ne 1 mm dhayamita probe. Sezvinoratidzwa pasi apa:

4. Kudzika matanho

4.1 Kana ipulagi yaiswa, pini yepasi inofanira kubatanidzwa kune socket yepasi kutanga, uye ikozvino-inotakura pini inofanira kusimbiswa. Kana ipuragi yabviswa, pini inotakura ikozvino inofanira kubvarura pini yepasi isati yadambura.

4.2 - Saizi yepasi terminal ichave yakafanana neyakaenzana magetsi conductor terminal saizi.

- Iyo Earth terminal yemagetsi anogona kudzorereka emagetsi ane pasi anobatika ichave yemukati.

- Iyo yepasi terminal yeyakagadziriswa socket-outlet ichagadziriswa kune hwaro kana kune chikamu chakanyatso kugadzika kune hwaro.

- Sleeve yepasi yeyakagadziriswa socket-outlet ichagadziriswa kune chigadziko kana kuchivharo. Kana yakanamirwa pachivharo, sleeve yekugadzika ichaita otomatiki uye yakavimbika kune iyo yekumisa terminal kana chivharo chiri panzvimbo yayo yakajairika. Mazita anofanirwa kunge ari sirivheri akapfachukira kana kuti anofanirwa kuve nekuora uye apfeke kuramba asingasviki pane sirivheri yakaiswa.

4.3 Mune zvigadziko zvakagadziriswa zvine zvigadziko zvepasi, zvikamu zvesimbi zvinosvikika izvo zvinozove mhenyu kana insulation yatadza inofanirwa kuve yakabatana zvachose uye yakachengeteka kune yepasi terminal.

4.4 Socket-outlet ine IP kodhi yakakwira kupfuura IPXO uye insulating enclosure ine inopfuura imwe tambo yekupinda ichave yakashongedzerwa neInternal fixed ground terminals, kana kupa nzvimbo yakakwana yekuyangarara materminal, inobvumira inopinda uye inobuda yekubatanidza kuti ive nechokwadi chekuenderera kweiyo. pasi redunhu.

4.5 Kubatana pakati pepasi terminal uye zviri nyore kusvikika simbi zvikamu zvinofanirwa kunge zvakaderera-resistant kubatana, uye kushorwa hakufanirwe kunge kwakakura kupfuura 0.05Ω.

4.6 Fixed socket-outlets inotarisirwa kupa dunhu risingapindire kuvhiringwa kwemagetsi kana midziyo yadzinobatirwa ichinge ine socket yepasi uye materminal ayo achange akaparadzaniswa nemagetsi kubva kune chero simbi inokwirisa kana kubva paivhu rinodzivirira iro rinogona kunge riri. yakabatana kune system. magetsi akapatsanurwa kubva kune mamwe akafumuka conductive zvikamu zvedunhu.

5.Terminals uye misoro

5.1 Rewirable fixed socket-outlets anofanirwa kunge ane screw-clamped terminals kana screwless terminals.

5.2 Mapulagi anogona kudzokororwa uye anotakurika socket-outlets anofanirwa kunge ane materminal ane threaded clamping.

5.3 Kana tambo dzakafanotengeswa dzichishandiswa, zvinofanirwa kucherechedzwa kuti mune screw-type terminals, iyo pre-soldered nzvimbo inofanirwa kunge iri kunze kwenzvimbo yekusunga kana yakabatana mukushandiswa kwakajairika.

5.4 Kunyangwe zvikamu zvinoshandiswa kusungirira maconductor muterminal zvinogona kushandiswa kuchengetedza terminal iri munzvimbo yakajairwa kana kudzivirira iyo terminal kubva kutenderera, haifanirwe kushandiswa kugadzirisa chero zvimwe zvikamu.

5.3 Thread clamp type terminal

-Threaded clamping terminals inofanirwa kukwanisa kubatanidza ma conductor asina kubatwa;

- Thread clamping terminals inofanirwa kunge iine simba rakakwana remuchina uye haifanirwe kugadzirwa nesimbi yakapfava kana simbi inokambaira;

- Thread clamping terminals anofanirwa kushingirira kune corrosion; thread clamping terminals haifanire kukuvadza zvakanyanya ma conductor kana uchiasunga;

-Threaded clamping terminals inogona kusungirira conductor pakati penzvimbo mbiri dzesimbi;

-Thread clamping terminal, kana uchisimbisa screw kana nati, hazvigoneke kuti waya dzeiyo hard single-core conductor kana iyo stranded conductor ibude;

-Thread clamp type terminals ichagadziriswa muplug ne socket nenzira yekuti maclamping screws kana nzungu haagone kusimbiswa kana kusunungurwa pasina kuita kuti terminal pachayo isununguke.

- Iyo clamping screws uye nzungu dzepasi terminals dzeshinda-clamp mhando dzinofanirwa kukiyiwa zvakakwana kudzivirira kusunungura netsaona; uye inofanira kunge isina-turusi.

-Thread clamp type earth terminals ichave zvekuti pasave nenjodzi yecorrosion inobva pakubata pakati pezvikamu izvi neconductor yemhangura yevhu kana mamwe masimbi akasangana nawo.

5.4 Screwless terminals ekunze econductor copper

- Ma Screwless terminals anogona kunge ari emhando anokodzera chete maconductor emhangura yakaoma, kana yemhando yakakodzera kune ese akaomarara uye akapfava emhangura conductor.

-Screwless terminals ichave inokwanisa kubatanidza makondukita asina kunyatso gadzirirwa.

-Threadless terminals inofanirwa kuchengetedzwa zvakanaka kune socket. Screwless terminals haifanirwe kuve yakasununguka nekuda kwekubatanidza kana kubviswa kwemakondakita panguva yekuiswa.

-Threadless terminals ichakwanisa kutsungirira kushushikana kwemakanika kunoitika panguva yekushandiswa kwakajairika.

-Threadless terminals ichakwanisa kumira kusimba kwemagetsi uye kupisa kunoitika panguva yekushandiswa kwakajairika.

6.1 Izvo zvikamu zvesocket sleeve zvinofanirwa kuve zvakanyungudika zvakakwana kuti ive nechokwadi chekubata kwakaringana kudzvinyirirwa kunopesana nemapini eplug.

6.2 Zvikamu zvesocket-outlet assembly inosangana nemapini eplug uye inoshandiswa kuwana magetsi kana plug yanyatsopinzwa musocket inowona kuti pane simbi inobatana pamativi maviri akapesana ega ega. pin.

6.3 Sleeve yesoketi inofanirwa kushingirira mukuora uye kupfeka.

6.4 Zvinodiwa zve insulating liners uye insulating zvipingamupinyi.

6.5 Socket-outlet ichagadzirwa kuti ifambise kuiswa kwemakondukita uye kubatana kwakakodzera kumaterminal, kumira kwakaringana kwemakondakita, kuve nyore kuchengetedza zvinhu zvikuru kumadziro kana kubhokisi, uye nzvimbo yakakwana.

6.6 Dhizaini ye socket-outlet haifanire kudzivirira kusangana kwakazara nepurugi yakakodzera nekuda kwechero protrusions kubva pakubata pamusoro. Kana plug yaiswa musocket, inotarwa nechiyero kuti gaka riri pakati penzvimbo yekubatanidza yeplug uye socket mating surface haifanire kudarika 1mm.

6.7 Pini yekugadzika inofanira kuva nesimba rakakwana remuchina.

6.8 Socket yepasi, phase socket uye neutral socket inofanira kuvharwa kudzivirira kutenderera.

6.9 Mitsara yesimbi yedunhu repasi haifanirwe kunge iine mabhura anogona kukuvadza kuvharwa kwemagetsi emagetsi.

6.10 Zvigadziko zvakaiswa mumabhokisi ekuisa zvichagadzirwa kuitira kuti conductor inopera inogona kugadziriswa mushure mokunge bhokisi rekuisa raiswa panzvimbo yakajairika asi isati yaiswa mubhokisi rekuisa.

6.11 Masuo etambo anofanirwa kubvumira kupinda kwetambo conduits kana sheaths kuti ipe yakakwana yekudzivirira yemagetsi kumatambo.

7. Kuchembera-kuramba uye hunyoro-uchapupu

7.1 Socket inofanira kuva nekusagadzikana kwekuchembera: mushure mekunge sampu yaiswa muvheni yekupisa ye70 ℃ ± 2 ℃ kwemaawa 168, sampuro haizove nekutsemuka uye zvinhu zvayo hazvizove zvinonamira kana kutsvedza.

7.2 Socket inofanira kuva nehunyoro-uchapupu: mushure mokunge sampu yachengetwa kwemaawa makumi mana nemasere pane imwe humidity ye 91% ~ 95% uye tembiricha ye40 ℃ ± 2 ℃, kudzivirira kwekudzivirira uye simba remagetsi rinofanira kuenderana nemirairo.

8. Insulation resistance uye simba remagetsi

8.1 Kudzivirira kwekudzivirira pakati pemapango ese akabatana pamwe chete nemuviri ndeye ≥5MΩ.

8.2 Kudzivirira kwekudzivirira pakati pematanda ose ndeye ≥2MΩ.

8.3 Isa muedzo wekutsungirira voltage we50Hz, 2KV ~ pakati pezvinhu zvese kweminiti imwe. Panofanira kunge pasina kupenya kana kuputsika.

9. Tembiricha inokwira

Mushure mekunge sampu yapfuura bvunzo yehupenyu, tembiricha yekukwira kwezviteshi zvayo haifanire kudarika 45K, tembiricha yekukwira yezvikamu zvesimbi zvinosvikika haifanire kudarika 30K, uye kukwira kwekushisa kwezvikamu zvisiri zvesimbi zvinosvikika hazvifanirwe kudarika 40K.

10. Kuputsa simba

Kune zvemagetsi zvemagetsi zvine rated voltage isingapfuuri 250 V uye yakayerwa ikozvino isingapfuuri 16 A, sitiroko yemidziyo yekuyedza inofanira kunge iri pakati pe50 mm ne60 mm.

Isai plug mukati nekubuda musocket ka50 (100 strokes), iyo plug-in uye yekudhonza-kunze mwero ndeiyi:

- Yemagetsi emidziyo ine yakayerwa ikozvino isingapfuuri 16 A uye yakayerwa voltage isingapfuuri 250V, 30 sitiroko paminiti;

-Kune zvimwe zvigadzirwa zvemagetsi, 15 shamhu paminiti.

Panguva yekuyedzwa, hapana yakatsiga arc flash inofanirwa kuitika. Mushure mekuedzwa, mufananidzo wacho uchave usina kukuvara izvo zvingakanganisa kuwedzera kushandiswa, uye gomba rekuisa repini richave risina kukuvara izvo zvinokanganisa kuchengetedzwa kwayo mukati mezvinoreva gwaro iri.

11. Kushanda kwakajairika (hupenyu bvunzo)

Zvishandiso zvemagetsi zvinofanirwa kumirisana nemakanika, magetsi uye ekupisa kushushikana kunobva mukushandiswa kwakajairwa pasina kupfeka zvisina kufanira kana zvimwe zvinokuvadza. Mudunhu rine rated voltage, rated current, COSφ=0.8±0.05, plug uye unplug 5000 times.

Munguva yekuedzwa, hapana inoenderera arc flash inofanirwa kuitika. Mushure mekuedzwa, muenzaniso haufanire kuratidza: kupfeka kunokanganisa kushandiswa kwemangwana; kuparara kweimba, insulating gaskets kana zvipingamupinyi, nezvimwewo; kukuvadza kune socket iyo inogona kukanganisa kushanda kwakajairika kweplug; kusununguka kwemagetsi kana ma mechanical connections; kubuda kwe sealant. leak.

12. Kudhonza-kunze simba

Iyo soketi inofanirwa kuve nechokwadi chekuti plug iri nyore kupinza uye kubvisa uye kudzivirira iyo plug kubva pasocket panguva yekushandiswa kwakajairika.

13. Mechanical simba

Zvemagetsi zvemagetsi, mabhokisi ekumisikidza pamusoro-akaiswa pamusoro, tambo dzakarukwa uye zvivharo zvinofanirwa kuve nesimba rakakwana remuchina kuti rimire kushushikana kwemakanika kunogadzirwa panguva yekuisa nekushandisa.

14.1 Sample inodziiswa muovheni yekushisa ye100°C ± 2°C kweawa imwe. Munguva yekuyedzwa, sampu haifanirwe kuita shanduko inogona kukanganisa kushandiswa kweramangwana, uye kana paine chisimbiso, haifanirwe kuyerera kuratidza mhenyu zvikamu. Mushure mebvunzo, chiratidzo chinofanirwa kunge chichiri kunyoreka.

14.2 Mushure mekudzvanywa kwebhora bvunzo, iyo indentation dhayamita haifaniri kudarika 2mm.

15

15.1 Zvese zvemagetsi uye zvemagetsi zvinongedzo zvinofanirwa kumirisana nemakanika kushushikana kunoitika mukushandiswa kwakajairwa.

15.2 Nema screws anobata tambo dze insulating materials nema screws anoda kusimba kana uchibatanidza magetsi ekushandisa panguva yekuisa, ona kuti anotungamirwa nemazvo mumaburi escrew kana nzungu.

15.3 Mabatiro emagetsi anofanirwa kunge ari ekuti kudzvanywa kwekubata hakufambiswe kuburikidza ne insulating material.

15.4 Screws nemarivets zvinofanirwa kukiiwa paunenge uchigadzira kubatanidza magetsi uye ma mechanical connections kudzivirira kusunungura nekutenderera.

15.5 Metal ikozvino-inotakura zvikamu zvinofanirwa kugadzirwa nesimbi inosangana nezvinodiwa zvemagetsi simba, magetsi conductivity uye corrosion properties.

15.6 Mazita anotsvedza panguva yekushandiswa kwakajairika anofanirwa kugadzirwa nesimbi isingaite ngura.

15.7 Self-tapping uye self-cutting screws haafaniri kushandiswa kubatanidza-zvino-kutakura zvikamu. Anogona kushandiswa kubatanidza pasi, kunze kwekunge angangoita maviri screws anoshandiswa.

16

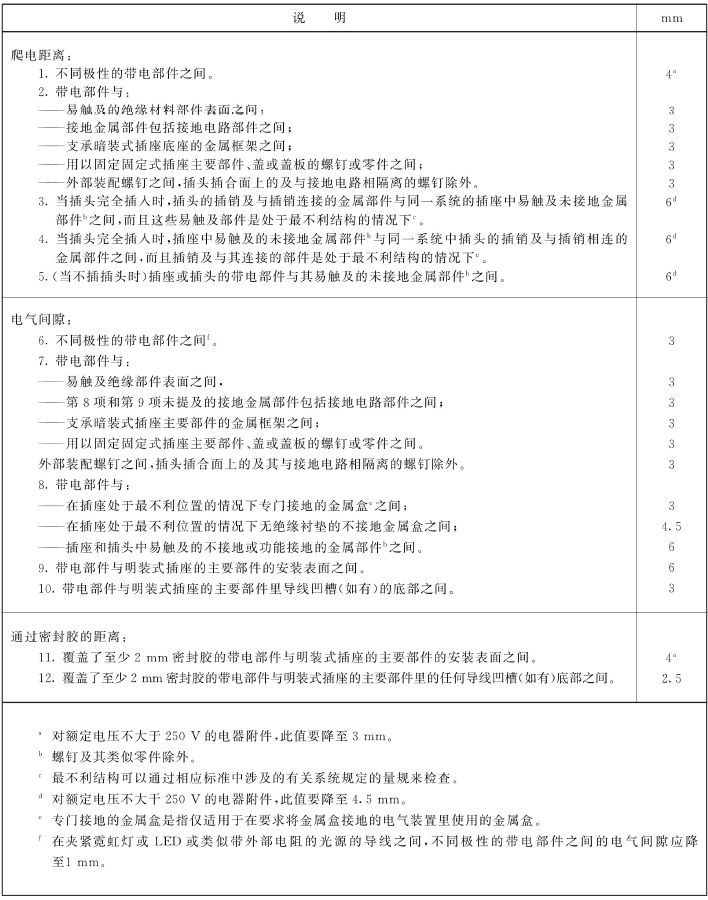

Creepage kureba, magetsi clearance uye chinhambwe kuburikidza nesealant ndeaya anotevera:

17.Abnormal kupisa uye murazvo kuramba we insulating zvinhu

17.1 Kupenya waya bvunzo (yakaedzwa zvinoenderana nezvikamu 4 kusvika gumi zveBS6458-2.1: 1984) Zvishandiso zvinodzivirira zvezvakagadziriswa zvino-zvinotakura zvikamu uye nzvimbo dzakadzika dzedunhu 850 ℃

17.2 Insulating zvinhu zvezvisina-yakagadziriswa-zvino-zvinotakura zvikamu uye zvakadzika dunhu zvikamu 650 ℃.

17.3 Mushure mekuedzwa, hapana murazvo unooneka uye hapana kupenya kunoramba kuripo, kana murazvo wakadzimwa kana kupenya kunorasika mukati memasekondi makumi matatu mushure mekunge waya inopenya yabviswa; pepa retishu haribati moto, uye pine board haipisi.

18.Anti-ngura kuita

Masimbi esimbi haafaniri kuratidza ngura mushure mekupasa bvunzo dzekuora.

Nguva yekutumira: Feb-05-2024