Kuongorora chikamu chisingasvikiki chebhizinesi remazuva ese, asi ndeipi iyo nyanzvi yekuongorora maitiro uye nzira? Mupepeti akaunganidza akakodzera kuunganidzwa kweFWW nyanzvi yekuongorora iwe, kuitira kuti kuongorora kwako kwezvinhu kuve kwakanyanya kushanda!

Chii chinonzi Goods Inspection (QC)

Vashandi vanoita basa rekuongorora vanobatanidzwa pamwe chete kunzi QC (pfupiso yeHunhu Controller).

Mabasa ekuongorora akaitwa neQC anonzi kuongorora uye akapatsanurwa maererano neQC inopa bato: kune 3 mhando, yekutanga bato kuongorora, yechipiri bato kuongorora uye yechitatu bato kuongorora: yekutanga bato iQC yakarongwa nemugadziri; wechitatu Bato rechipiri ndiyo QC inotumirwa nekambani yevatengi;

Kuongororwa nemunhu wechitatu akapihwa nesangano rekuongorora rekunze kune mutengi webato rechipiri. FWW inopa wechitatu-bato rekuongorora masevhisi

Iyo yekuongorora sevhisi yakapihwa neFWW yakakamurwa kuita: yekupedzisira yekuongorora FQC uye yepakati-yekugadzira yekuongorora Pa-line QC zvinoenderana nedanho rekupedzisa chigadzirwa. Matanho asara ndee-in-production inspections, ayo ari ekutanga kudzora zviitiko zvemhando yechigadzirwa.

Saizi Saizi uye Inobvumidzwa Chikamu (AQL)

Nzira yakachengeteka yekuongorora zvinhu ndeyekuongorora 100% yezvinhu zvose, asi izvi zvinoda nguva yakawanda yeQC, kunyanya kune mabheji makuru.

Saka tingawana sei inonzwisisika sampling level yekuenzanisa njodzi yemhando yechigadzirwa uye mutengo weQC. Iyi chiyero chepakati ndeye "Sample size". Nekudzorwa kwehuwandu hwemasamples, dambudziko rinotevera iro QC rinoda kutarisana naro nderekutsvaga hurema mukuita kwekuongorora sampling, mangani akaremara, mangani akaremara anogamuchirwa nebatch iyi, ingani zvikanganiso, izvi zvinotumirwa zvinoda kurambwa? Iyi ndiyo nhanho inogamuchirika (AQL: Inogamuchirika Hunhu Level)

Defect level (Yakakosha, Yakakura, Diki)

Kukanganisa kunowanikwa panguva yekuongorora kunozoiswa muzvikamu zvitatu zvinoenderana nekuoma kwavo:

Mienzaniso yetsanangudzo dzegiredhi Critical (Cr.) hurema hunouraya hunogona kukonzera kukanganisa kumuviri wemunhu kana kutyora mitemo nemirau, senge mipendero yakapinza, acute angles, kubuda kwemagetsi, nezvimwewo. (kazhinji, matambudziko ebhakodhi anozotsanangurwa seCr.) ; Zvigadzirwa zvakasimbiswa, hapana hukuru (Ma.) hurema hwakakura hwakadai seEC Mark, mamwe mabasa akakosha kana kukanganisa kutaridzika pane zvigadzirwa senge thermal insulation cups, kutadza kudhinda logo, etc. Zvidiki (Mi.) zvidiki (Mi.) zvidiki diki senge diki diki diki. pazvigadzirwa zvakaita sezvigadzirwa Zvishoma zvikweshwa pamusoro, kudhinda kwakashata zvishoma, nezvimwe.

Mumamiriro ezvinhu akajairwa, QC ine ruzivo inogona kuona kurongeka kwehurema hunowanikwa panguva yekuongorora ivo pachavo maererano nemisimboti iri pamusoro. Zvisinei, kuitira kuti pave nechokwadi chokuti maQC ose anobatanidzwa haana kujeka muchikwata che defect, vamwe vatengi vachagadzira Defective Classification List (DCL Defective Classification List), nyora zvose zvakakanganiswa zvine chokuita nechigadzirwa mune defect classification list, uye kuratidza. chikanganiso chiyero icho chakakanganisika chega chega chinofanira kutongwa. .

Kushandisa tafura yesampling plan

Mushure mekuunza pfungwa dzeSample saizi, AQL uye chirema nhanho, iyo chaiyo application inoda QC kuti itarise chirongwa chesampling. Mafomu e2 anoshandiswa pamwe chete, yekutanga inogadzirisa dambudziko rekuti ingani yekukwevera, uye yechipiri inogadzirisa dambudziko rekuti vangani zvikanganiso zvinogona kurambwa.

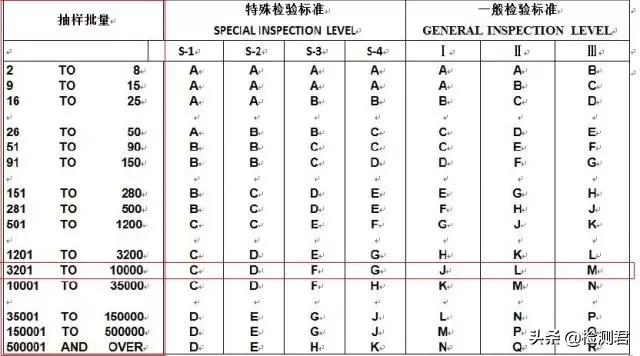

Nhanho yekutanga: Tarisa fomu rekutanga, tsvaga chikamu chepakati chehuwandu hwehuwandu hwehuwandu hwezvigadzirwa mu "Sampling lot" koramu, wobva watarisa zvakachinjika muchinjiro we "Special Inspection Standard" uye "General Inspection Standard" kuti uone. Huwandu hwesampling; 2. "General inspection standard" inoshandiswa pakuenzanisa kwekuongorora kwekuona. Kune akawanda ekuongorora akazara, ayo akakamurwa kuita nhanho nhatu, Level-I, II, uye III. Iyo yakakura nhamba, iyo yakakura nhamba yekuenzanisira; 3. "Inspection standard" inoshandiswa pakuenzanisa basa uye kuongorora ukuru. Huwandu hwekuongorora hudiki, hwakakamurwa kuita 4 mamakisi, S-1, S-2, S-3, S-4. Iyo yakakura nhamba, iyo yakakura nhamba yesampling.

Nhamba yekusarudzika yemasampuli eFWW ndeye Level-II, S-2. Kana huwandu hwese hwezvigadzirwa mukuongorora uku huri 5000pc (renji 3201-10000), zvinoenderana neiyo default sampling standard yeFWW, iyo sampling kodhi ye general (kuonekwa) yekuongorora ndeye L; iyo sampling kodhi yeyakakosha (basa) yekuongorora ndeye D

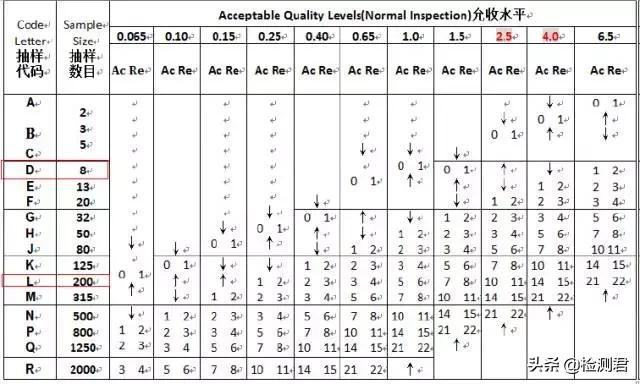

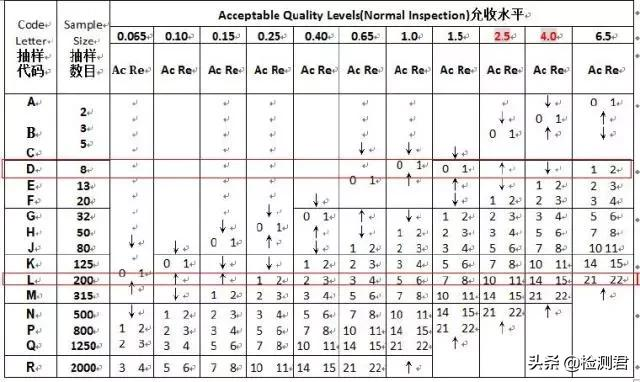

Nhanho yechipiri ndeyekutarisa tafura yechipiri, apo L inofanana nenhamba yekuenzanisa ye200pc; D inoenderana nesampling nhamba ye8pc.

Nhanho yechitatu 1.Mutafura yechipiri, kune makoramu maviri eAc Re pasi pekukosha kweyero yega yekushivirira. Apo nhamba yose yezvikanganiso zvakadaro ≤Ac kukosha, zvinhu zvinogona kugamuchirwa; apo nhamba yose yezvakaremara zvakadaro ≥Re value, zvinhu zvinorambwa. Nekuda kwehukama hwakafanana hune musoro, ese Re ndeye 1 kupfuura Ac. 0 inoshandiswa seyero yekugamuchirwa yakakosha, iyo isingaonekwe mutafura ino. Zvinoreva kuti chirema hachigoni kuvapo. Kana paine 1 chakaremara chakadaro, zvinhu zvinorambwa; 2. The default AQL of FWW is Cr. 0; Ma. 2.5; Mi. 4.0, kana zvinoenderana nedanho rekugamuchirwa iri: L (200pc) inoenderana naMa. Ac Re ye10 11, kureva kuti, kana huwandu hwehuwandu hwekuremara huri pasi kana kuenzana ne10, zvinhu zvinogona kugamuchirwa; apo huwandu hwehuwandu hwekuremara huri ≥ 11, zvinhu zvinorambwa. Saizvozvo, iyo Ac Re yeMi. iri 14 15.D (8pc) inoenderana naMa. i“↑”, inomiririra mwero wekugamuchirwa nezviri pamusoro, kureva, 0 1; inoenderana Mi. iri “↓”, inomiririra chirevo chedanho rinotenderwa pazasi. Chiyero chekugamuchira, kureva, 1 2Cr. 0, zvinoreva kuti zvirema zvinouraya hazvibvumidzwe kuwanikwa

Check List

Cheki list (Check List) inowanzoshandiswa mumabasa ekuongorora eQC. Ese mapoinzi anoda kutariswa kune zvigadzirwa akanyorwa mune rondedzero kudzivirira kusiiwa muchirongwa chekuongorora cheQC. Kune vatengi venguva refu yekubatana, FWW inogadzirira cheki runyoro pamberi. Rondedzero yeCheki inowanzo shandiswa pamwe chete neiyo Defective Classification Rondedzero (DCL Yakashata Classification Rondedzero).

Iyo yakakosha maitiro ekuongorora kweQC

Inspection process

STEP 1FWW inosimbisa izvo zvinodikanwa zvekuongororwa nemutengi kana uchinyorera kuongororwa, uye tsanangura saizi yeSample uye AQL. uye pfuura iyo data kune yakakodzera QC

STEP 2QC ichabata fekitori kanenge zuva 1 risati rasvika zuva rekuongorora kuti vaone kana zvinhu zvapera sezvinodiwa.

STEP 3 Pazuva rekuongororwa, QC inotanga kuverenga FWW Kutendeseka Chirevo kufekitari.

STEP 4 Tevere, QC inotanga kusimbisa kupedzwa kwese kwezvinhu (kana chigadzirwa chakazara 100%; iyo yekurongedza ndeye 80% yakakwana)

STEP 5 Dhirowa mabhokisi zvichienderana nehuwandu hwehuwandu hwemabhokisi

STEP 6 Tarisa kunze kwebhokisi ruzivo, yepakati bhokisi ruzivo, ruzivo rwechigadzirwa

STEP 7 Sampling tarisa chigadzirwa chitarisiko zvinoenderana nenhanho-II nhanho, chigadzirwa basa uye saizi zvinoenderana neS-2 level sampling cheki

STEP 8 Pfupisa uye uverenge kana huwandu hwese hwehurema hunodarika mwero, uye simbisa nefekitari.

STEP 9 Mushure mekuongorora, gadzirira FWW yekuongorora report uye kutumira mushumo kune vanoongorora

STEP 10 Mushure memushumo vashandi vaongorora mushumo, tumira mutengi

Nguva yekutumira: Jul-31-2022