Litekanyetso tsa naha tse tlamang le IEC li na lelitlhoko tsa tekhenikibakeng sa ho tšoaea, ho sireletsa khahlanong le ts'oenyeho, sebopeho, ts'ebetso ea motlakase, ts'ebetso ea mochini, joalo-joalo ea li-plug le li-sockets bakeng sa merero ea malapa le tse tšoanang. Lintlha tse latelang ke litekanyetso le mekhoa ea tlhahlobo ea li-plug le li-sockets.

1. Tlhahlobo ea ponahalo

2. Tlhahlobo ea mahlakore

3. Tšireletso khahlanong le ts'oaetso ea motlakase

4. Mehato ea ho theola fatše

5. Terminals le Headers

6. Sebopeho sa sokete

7. Ho tsofala ha ho tsofala le ho thibela mongobo

8. Insulation resistance le matla a motlakase

9. Ho phahama ha mocheso

10. Ho senya matla

11. Ts'ebetso e tloaelehileng (teko ea bophelo)

12. Ho hula matla

13. Matla a mochine

14. Teko ea ho hanyetsa mocheso

15. Li-screw, likarolo tse tsamaisang hona joale le likamano tsa tsona

16. Bohole ba creepage, tumello ea motlakase, sebaka sa ho tiisa ho kenella ho kenella

17. Ho hanyetsa mocheso o sa tloaelehang le ho hanyetsa lelakabe la thepa ea insulating

18. Ts'ebetso e khahlanong le mafome

1. Tlhahlobo ea ponahalo

1.1 Likarolo tse kholo tsa sehlahisoa li lokela ho ba le matšoao a latelang:

- E lekantsoe hajoale (amps)

- Matla a lekantsoeng (volts)

- Letšoao la phepelo ea matla;

-Lebitso, letshwao la kgwebo kapa letshwao la boitsebahatso la moetsi kapa morekisi;

-Nomoro ea sehlahisoa

- Letšoao la setifikeiti

1.2 Ho lokela ho sebelisoa matšoao a nepahetseng sehlahisoa:

1.3 Bakeng sa li-sockets tse tsitsitseng, matšoao a latelang a lokela ho tšoauoa likarolong tse kholo:

- E lekanyelitsoe hona joale, matla a motlakase a lekantsoeng le thepa ea phepelo ea motlakase;

-Lebitso kapa letšoao la khoebo kapa letšoao le khethollang la moetsi kapa morekisi;

-Bolelele ba ho kenya letsoho bo lokelang ho tlosoa pele conductor e kenngoa ka har'a terminal e se nang screwless (haeba e teng);

- Haeba sokete e loketse feela ho hokahanya lithapo tse thata, ho lokela ho ba le pontšo ea hore setsi se se nang screwless se loketse feela ho hokahanya likhoele tse thata;

-Nomoro ea mohlala, e ka bang nomoro ea lethathamo.

1.4 Boleng ba ponahalo: Bokaholimo ba sokete e lokela ho ba boreleli, khetla e lokela ho ba e ts'oanang, 'me ha ea lokela ho ba le li-pores, mapetsong, li-indent, li-bumps, tšenyo, matheba kapa litšila; likarolo tsa tšepe ha lia lokela ho ba le oxidation, matheba a mafome, deformation, litšila, 'me seaparo se lokela ho ba se ts'oanang le se khanyang.

1.5 Packaging: Lebitso la sehlahisoa, litlhaloso, khoutu ea thepa, lebitso la feme, bongata, le nomoro ea batch ea tlhahiso li lokela ho tšoauoa lebokoseng la ho paka.

2. Tlhahlobo ea mahlakore

2.1 Sokete e tlameha ho kenngoa le ho ntšoa ka makhetlo a 10 ka polaka e nang le boholo bo boholo ba phini bo fihlelang litlhoko tsa maemo a tšoanang. Boholo ba phini bo hlahlojoa ka ho metha kapa ho sebelisa gauge.

2.2 Ka mokhoa o itseng, plug e ke ke ea kopana le li-socket outlets tse latelang:

- Li-sockets tse nang le litekanyetso tse phahameng tsa motlakase kapa litekanyetso tse tlase tsa hona joale;

- Li-sockets tse nang le palo e fapaneng ea li-electrode;

3. Ptshitiso kgahlanong le ho tsokoa ke motlakase

3.1 Ha plug e kentsoe ka botlalo ka har'a sokete, likarolo tse phelang tsa plug li tlameha ho se fihlellehe. Lekola hore na e tšoaneleha ka tlhahlobo. Li-socket-outlets tse tsitsitseng, li-mated plugs le li-portable socket-outlets li tla hahoa le ho raloa hore, ha li kentsoe kapa li kenngoe ka mehala bakeng sa tšebeliso e tloaelehileng, likarolo tse phelang li ke ke tsa fumaneha le ka mor'a ho tlosoa ha likarolo tse fumanehang ntle le lisebelisoa. Ho joalo le ka likarolo tse ka tlosoang.

3.2 Ha lisebelisoa tsa motlakase li kenyelelitsoe 'me li kenngoa ho latela litlhoko tse tloaelehileng tsa tšebeliso, li ntse li le likarolo tse fumanehang, ntle le li-screws tse nyenyane le likarolo tse tšoanang tse sebelisetsoang ho lokisa likarolo tse kholo le likoahelo le likoahelo tsa li-sockets, tse arohaneng le tse phelang. dikarolo. Li lokela ho etsoa ka thepa ea insulating. thepa.

3.3 Pin efe kapa efe ea plug e ke ke ea khona ho kopana le sokete e phelang ea sokete ha phini e 'ngoe e le boemong bo fihlellehang.

3.4 Likarolo tse kantle tsa plug li tla etsoa ka thepa e sireletsang tšireletso. Sena ha se akarelletse likarolo tse ka fihlellehang joalo ka likurufu tsa ho kopanya, lithakhisa tse tsamaisang hona joale, lithakhisa, litšepe tsa motheo, le mehele ea tšepe e pota-potileng liphini.

3.5 Sokete e nang le lemati le sireletsang, ha plug e ntšoa, sokete e phelang e ka sireletsoa ka bo eona.

3.6 Sekoahelo sa motheo sa sokete ha sea lokela ho holofala ka tsela e ka behang tšireletseho kotsing ka lebaka la ho kenngoa ha polaka.

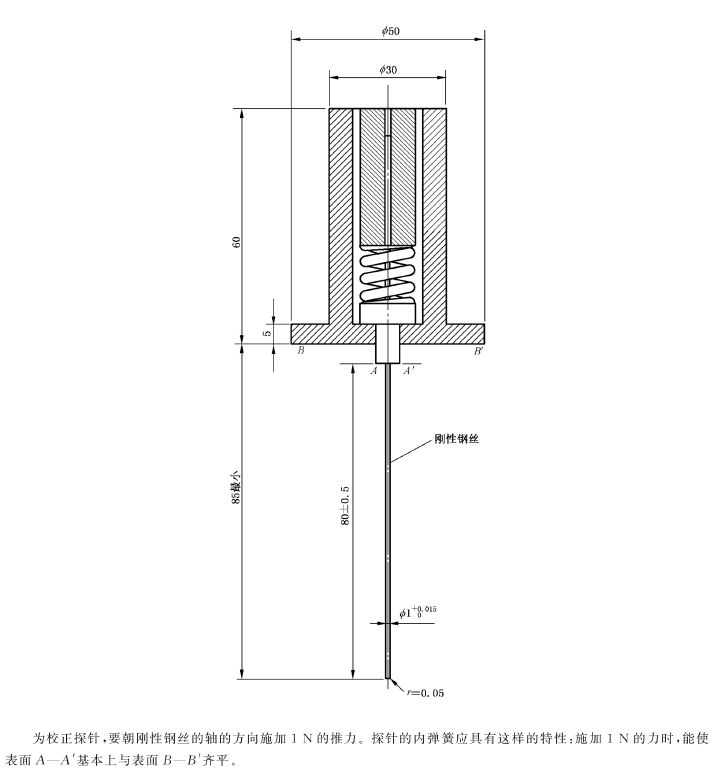

3.7 Bakeng sa li-sockets tse nang le tšireletso e matlafalitsoeng, ha li kentsoe le lithapo ho ea ka litlhoko tse tloaelehileng tsa ts'ebeliso, likarolo tse phelang li lokela ho se fumanehe ka probe ea bophara ba 1 mm. Joalokaha ho bontšitsoe ka tlase:

4. Mehato ea ho theola fatše

4.1 Ha plug e kenngoa, pin ea fatše e lokela ho kopanngoa le sekoti sa fatše pele, ebe pin e nang le hona joale e lokela ho matlafatsoa. Ha polaka e tlosoa, phini e nang le hona joale e lokela ho hakolla pele phini ea fatše e khaoha.

4.2 - Saese ea theminale ea fatše e tla tšoana le boholo ba theminale ea khondara ea motlakase e tsamaellanang le eona.

- Terminal ea lefats'e ea lisebelisoa tsa motlakase tse khutlisehang tse nang le likhokahano tsa lefatše e tla ba tsa kahare.

- Terminal ea lefats'e ea socket-outlet e tsitsitseng e tla ts'oaroa botlaaseng kapa karolong e tiileng e tiileng botlaaseng.

- Mokotla oa motheo oa socket-outlet o tsitsitseng o tla ts'oaroa motheong kapa sekoahelong. Haeba e tsitsitse sekoahelong, letsoho le thellang le tla hokela ka mokhoa o ikemetseng le ka mokhoa o ts'eptjoang setsing sa ho theola ha sekoaelo se le maemong a sona a tloaelehileng. Mabitso a lokela ho ba silevera a koahetsoeng kapa a be le kutu 'me a se ke a apara ka tlaase ho silevera.

4.3 Ka li-sockets tse tsitsitseng tse nang le li-sockets, likarolo tsa tšepe tse fihlellehang tse tla phela ha ho koala ho hloleha ho lokela ho hokahanngoa ka ho sa feleng le ka mokhoa o sireletsehileng sebakeng sa ho theola fatše.

4.4 Socket-outlet e nang le khoutu ea IP e phahameng ho feta IPXO le sebaka se sireletsang metsi se nang le cable e fetang e le 'ngoe se tla ba le li-terminals tse tsitsitseng ka hare, kapa ho fana ka sebaka se lekaneng bakeng sa liteishene tse phaphametseng, ho lumella likhokahano tse kenang le tse tsoang ho netefatsa tsoelo-pele ea potoloho ea fatše.

4.5 Khokahano pakeng tsa setsi sa fatše le likarolo tsa tšepe tse fumanehang habonolo e lokela ho ba khokahanyo e fokolang, 'me ho hanyetsa ha hoa lokela ho ba kholo ho feta 0.05Ω.

4.6 Li-socketouts tse tsitsitseng tse reretsoeng ho fana ka potoloho e ke keng ea kena-kenana le tšitiso ea motlakase ha lisebelisoa tseo li hokeletsoeng ho tsona li tla ba le sokete ea ho thetheha 'me li-terminals li tla aroloa ka motlakase ho tloha holim'a tšepe efe kapa efe kapa mobung o sirelletsang o ka bang teng. e hokahaneng le sistimi. e arohaneng le motlakase ho tsoa likarolong tse ling tse pepeneneng tsa potoloho.

5.Litheminale le lihlooho

5.1 Li-sockets tse tsitsitseng tse ka khutlisetsoang morao li tla kengoa li-terminals tse nang le screw-clamp kapa li-screwless terminals.

5.2 Li-plug tse tsosolositsoeng le li-socket outlets tse nkehang habonolo li tla kengoa li-terminals tse nang le likhoele tse khoeleng.

5.3 Haeba lithapo tse rekisoang esale pele li sebelisoa, hoa lokela ho hlokomeloa hore li-terminals tsa mofuta oa screw, sebaka sa pele se rekisoang se lokela ho ba ka ntle ho sebaka sa clamping ha se kopantsoe ka mokhoa o tloaelehileng.

5.4 Le hoja likarolo tse sebelisetsoang ho tiisa li-conductors tsa theminale li ka sebelisoa ho boloka theminale e le boemong bo tloaelehileng kapa ho thibela theminale ho potoloha, ha ea lokela ho sebelisoa ho lokisa likarolo tse ling.

5.3 Theminale ea mofuta oa khoele

-Threaded clamping terminals e lokela ho khona ho hokela li-conductor tse sa sebetsoeng;

- Li-terminals tsa likhoele li lokela ho ba le matla a lekaneng a mochini 'me ha lia lokela ho etsoa ka tšepe e bonolo kapa tšepe e tloaetseng ho tsukutleha;

- Li-terminals tsa likhoele li lokela ho hanana le kutu; li-terminal clamping tsa likhoele ha lia lokela ho senya li-conductor haholo ha li li koala;

-Threaded clamping terminals ka ka tieo clamp conductor pakeng tsa tse peli tse tšepe holim'a metsi;

-Thread clamping terminal, ha o tiisa screw kapa nut, ho ke ke ha khoneha hore lithapo tsa khondara e thata e le 'ngoe kapa sekontiri se tsielehileng se tsoe;

- Li-terminals tsa mofuta oa khoele li tla lokisoa plug le soketeng ka tsela eo li-clamping screws kapa linate li ke keng tsa tiisetsoa kapa tsa lokoloha ntle le ho etsa hore theminale ka boeona e theohe.

- Li-clamping screws le linate tsa li-terminals tsa fatše tsa mofuta oa khoele li lokela ho notleloa ka ho lekaneng ho qoba ho lokoloha ka phoso; 'me e lokela ho se be le lisebelisoa.

-Thread clamp Earth terminals e tla ba joalo hore ho se be le kotsi ea ho bola e bakoang ke ho kopana lipakeng tsa likarolo tsena le conductor ea koporo ea mobu kapa litšepe tse ling tse amanang le eona.

5.4 Li-terminals tse se nang Screwless bakeng sa li-conductor tsa ka ntle tsa koporo

- Li-terminals tse se nang li-Screwless li ka ba tsa mofuta o loketseng feela li-conductor tsa koporo tse thata, kapa tsa mofuta o loketseng li-conductor tse thata le tse bonolo tsa koporo.

- Li-terminals tse se nang Screwless li tla khona ho hokela li-conductors tse sa lokisoang ka ho khetheha.

- Li-terminals tse se nang likhoele li lokela ho tiisetsoa hantle ho soketeng. Li-terminals tse se nang lisebelisoa ha lia lokela ho lokoloha ka lebaka la ho hokela kapa ho khaoha ha li-conductor nakong ea ho kenya.

- Li-terminals tse se nang likhoele li tla khona ho mamella khatello ea maikutlo e etsahalang nakong ea ts'ebeliso e tloaelehileng.

- Li-terminals tse se nang li-threadless li tla khona ho mamella khatello ea motlakase le ea mocheso nakong ea ts'ebeliso e tloaelehileng.

6.1 Likarolo tsa sleeve ea sokete li lokela ho ba elastic ka ho lekaneng ho etsa bonnete ba hore khatello e lekaneng ea ho kopana khahlanong le lithapo tsa plug.

6.2 Likarolo tsa kopano ea socket-outlet tse hokahaneng le lithakhisa tsa plug 'me li sebelisetsoa ho hokahanya motlakase ha plug e kentsoe ka botlalo soketeng li tla etsa bonnete ba hore ho na le khokahano ea tšepe bonyane mahlakoreng a mabeli a fapaneng a mang le a mang. pin.

6.3 Letsopa la sokete le lokela ho hana ho bola le ho senyeha.

6.4 Litlhokahalo tsa li-insulating liner le litšitiso tse sireletsang tšireletso.

6.5 Socket-outlet e tla hahuoa ho thusa ho kenya li-conductor le khokahanyo e nepahetseng ho li-terminals, boemo bo nepahetseng ba li-conductors, boiketlo ba ho boloka likarolo tse kholo leboteng kapa lebokoseng, le sebaka se lekaneng.

6.6 Moralo oa socket-outlet ha oa lokela ho thibela ho nyalana ka ho feletseng le polaka e amehang ka lebaka la litšubuhlellano tse tsoang sebakeng sa ho tsoallana. Ha plug e kenngoa ka har'a sokete, ho khethoa ka tekanyo ea hore lekhalo pakeng tsa sebaka sa ho nyalana sa plug le sebaka sa ho kopanya socket ha sea lokela ho feta 1mm.

6.7 Pini ea fatše e lokela ho ba le matla a lekaneng a mochine.

6.8 Sokete ea fatše, sokete ea mohato le sokete e sa nke lehlakore e lokela ho notleloa ho thibela ho potoloha.

6.9 Lisebelisoa tsa tšepe tsa potoloho ea fatše ha lia lokela ho ba le li-burrs tse ka senyang ho kenngoa ha li-conductor tsa matla.

6.10 Li-sockets tse kenngoa ka har'a mabokose a ho kenya li tla etsoa e le hore lipheletso tsa conductor li ka sebetsoa ka mor'a hore lebokose la ho kenya le kenngoe sebakeng se tloaelehileng empa pele sokete e kenngoa ka lebokoseng la ho kenya.

6.11 Menyako ea lithapo e lokela ho lumella ho kena ha li-conduits tsa cable kapa sheaths ho fana ka tšireletso e felletseng ea mochini bakeng sa likhoele.

7. E thibela ho tsofala le ho thibela mongobo

7.1 Socket e lokela ho ba le khanyetso ea botsofali: ka mor'a hore sampuli e pepesehe ka ontong ea mocheso oa 70 ℃ ± 2 ℃ bakeng sa lihora tsa 168, sampuli e ke ke ea e-ba le mapheo 'me thepa ea eona e ke ke ea khomarela kapa ea thella.

7.2 Sokete e lokela ho ba bopaki ba mongobo: ka mor'a hore sampuli e boloketsoe lihora tse 48 ka mongobo o lekanyelitsoeng oa 91% ~ 95% le mocheso oa 40 ℃ ± 2 ℃, ho hanyetsa ho kenya letsoho le matla a motlakase ho lokela ho lumellana le melao.

8. Insulation resistance le matla a motlakase

8.1 Tšireletso ea ho itšireletsa pakeng tsa lipalo tsohle tse kopantsoeng hammoho le 'mele ke ≥5MΩ.

8.2 Ho hanyetsa ho kenngoa pakeng tsa lipalo tsohle ke ≥2MΩ.

8.3 Kenya teko ea ho mamella voltage ea 50Hz, 2KV ~ pakeng tsa likarolo tsohle bakeng sa motsotso o le mong. Ha hoa lokela ho ba le ho thekesela kapa ho senyeha.

9. Ho phahama ha mocheso

Ka mor'a hore sampuli e fetise tlhahlobo ea bophelo, ho phahama ha mocheso oa li-terminals tsa eona ha hoa lokela ho feta 45K, mocheso o phahameng ka ho fetisisa oa likarolo tsa tšepe tse fihlellehang ha oa lokela ho feta 30K, 'me ho phahama ha mocheso oa likarolo tse fumanehang tseo e seng tsa tšepe ha hoa lokela ho feta 40K.

10. Ho senya matla

Bakeng sa lisebelisoa tsa motlakase tse nang le voltage e lekantsoeng e seng kholo ho feta 250 V le hajoale e lekantsoeng e seng kholo ho 16 A, sekhahla sa lisebelisoa tsa tlhahlobo se lokela ho ba pakeng tsa 50 mm le 60 mm.

Kenya polaka ka hare le ho tsoa ka soketeng makhetlo a 50 (li-stroke tse 100), sekhahla sa plug-in le ho tsoa ke:

- Bakeng sa lisebelisoa tsa motlakase tse nang le motlakase o sa feteng 16 A le motlakase o sa feteng 250V, lichapo tse 30 ka motsotso;

- Bakeng sa lisebelisoa tse ling tsa motlakase, liropo tse 15 ka motsotso.

Nakong ea tlhahlobo, ha hoa lokela ho etsahala arc flash e tsitsitseng. Ka mor'a tlhahlobo, mohlala o tla lokoloha tšenyo e ka amang ts'ebeliso e eketsehileng, 'me lesoba la ho kenya pini le ke ke la ba le tšenyo e ka amang polokeho ea eona ka har'a moelelo oa tokomane ena.

11. Ts'ebetso e tloaelehileng (teko ea bophelo)

Lisebelisoa tsa motlakase li lokela ho khona ho mamella likhatello tsa mochini, tsa motlakase le tsa mocheso tse hlahang ts'ebelisong e tloaelehileng ntle le ho roala ho sa hlokahaleng kapa litlamorao tse ling tse kotsi. Potolohong e nang le voltage e lekantsoeng, e lekantsoeng hajoale, COSφ=0.8±0.05, plug le ho notlolla makhetlo a 5000.

Nakong ea tlhahlobo, ha ho na arc flash e tsoelang pele e lokelang ho etsahala. Ka mor'a tlhahlobo, mohlala ha oa lokela ho bontša: ho apara ho neng ho tla ama tšebeliso ea nako e tlang; ho senyeha ha matlo, li-gaskets tse sireletsang kapa litšitiso, joalo-joalo; tšenyo ea sokete e neng e tla ama ts'ebetso e tloaelehileng ea plug; likhokahano tse hlephileng tsa motlakase kapa tsa mochini; ho dutla ha sealant. dutla.

12. Ho hula matla

Sokete e lokela ho etsa bonnete ba hore plug e bonolo ho kenya le ho e ntša le ho thibela plug ho tsoa ka soketeng nakong ea tšebeliso e tloaelehileng.

13. Matla a mochine

Lisebelisoa tsa motlakase, mabokose a kentsoeng ka holim'a metsi, litšoelesa tse nang le khoele le likoahelo li lokela ho ba le matla a lekaneng a mochine ho mamella khatello ea mochine e hlahisoang nakong ea ho kenya le ho sebelisoa.

14.Teko ea ho hanyetsa mocheso

14.1 Mohlala o futhumatsoa ka ontong ea mocheso oa 100 ° C ± 2 ° C bakeng sa hora e le 'ngoe. Nakong ea tlhahlobo, sampole ha ea lokela ho ba le liphetoho tse tla ama ts'ebeliso ea nako e tlang, 'me haeba ho na le sealant, ha ea lokela ho phalla ho pepesa likarolo tse phelang. Ka mor'a tlhahlobo, letšoao le ntse le lokela ho ba le balehang.

14.2 Ka mor'a teko ea khatello ea bolo, bophara ba indentation bo ke ke ba feta 2mm.

15

15.1 Lihokelo ka bobeli tsa motlakase le tsa mochini li lokela ho mamella khatello ea mochini e etsahalang ts'ebelisong e tloaelehileng.

15.2 Bakeng sa li-screws tse kenyang likhoele tsa thepa e sireletsang le likurufu tse hlokang ho tiisoa ha ho hokeloa lisebelisoa tsa motlakase nakong ea ho instola, etsa bonnete ba hore li tataisoa ka nepo ho likoti kapa linate.

15.3 Likhokahano tsa motlakase li lokela ho ba joalo hore khatello ea ho kopana e se ke ea fetisoa ka thepa ea insulating.

15.4 Li-screw le li-rivets li lokela ho notleloa ha ho etsoa likhokahanyo tsa motlakase le likhokahanyo tsa mochini ho thibela ho hlephisa le ho potoloha.

15.5 Likarolo tsa tšepe tse tsamaisang hona joale li lokela ho etsoa ka tšepe e fihlelang litlhoko tsa matla a mochini, ho tsamaisa motlakase le thepa ea kutu.

15.6 Mabitso a tla thella nakong ea ts'ebeliso e tloaelehileng a lokela ho etsoa ka tšepe e sa bolaeeng ke ho bola.

15.7 Li-screws tsa ho itšeha le tsa ho itšeha li ke ke tsa sebelisoa ho hokahanya likarolo tse tsamaisang hona joale. Li ka 'na tsa sebelisoa bakeng sa likhokahano tsa lefats'e, ha feela ho sebelisoa li-screw tse peli.

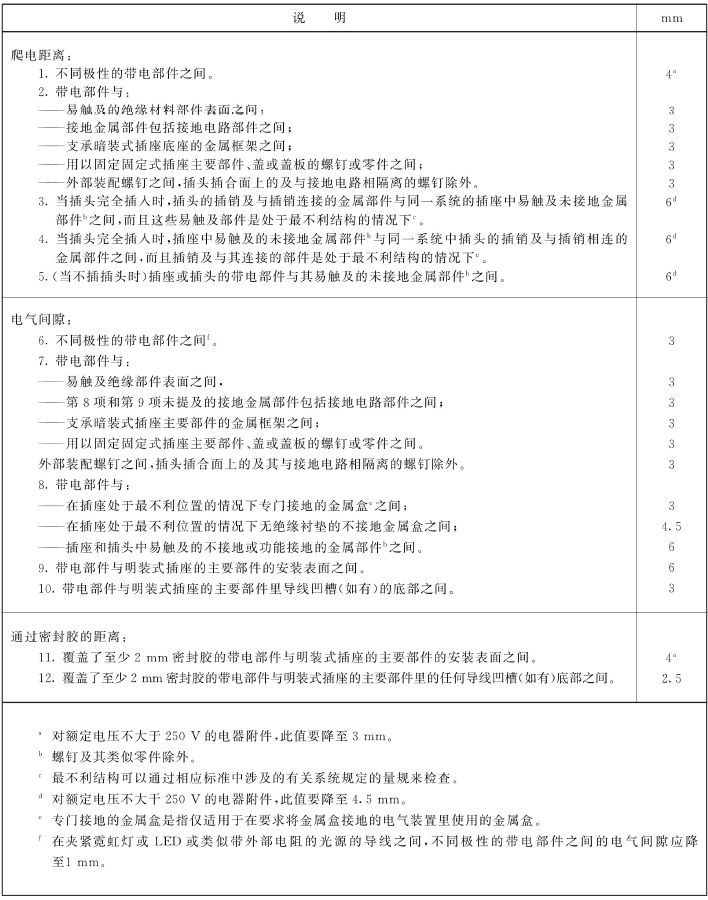

16.16. Bohole ba ho phunyeha, tumello ea motlakase, ka bohole ba ho tiisa

Sebaka sa creepage, clearance ea motlakase le sebaka sa sealant ke tse latelang:

17.Mocheso o sa tloaelehang le ho hanyetsa lelakabe la thepa ea ho itšireletsa

17.1 Teko ea terata e khanyang (e lekoa ho latela poleloana 4 ho isa ho 10 ea BS6458-2.1: 1984) Lisebelisoa tse sireletsang lisebelisoa bakeng sa likarolo tse tsitsitseng tse tsamaisang hona joale le likarolo tsa potoloho tse thehiloeng fatše 850 ℃

17.2 Lisebelisoa tse sireletsang tsa likarolo tse sa tsitsitseng tse tsamaisang hona joale le likarolo tsa potoloho tse thehiloeng fatše 650 ℃.

17.3 Ka mor'a tlhahlobo, ha ho na lelakabe le bonahalang 'me ha ho na khanya e tsoelang pele, kapa lelakabe le tima kapa khanya e lahleheloa ke metsotsoana ea 30 ka mor'a hore terata e khanyang e tlosoe; pampiri ea 'mele ha e che, 'me letlapa la phaene ha le che.

18. Ts'ebetso e khahlanong le mafome

Likarolo tsa tšepe li ke ke tsa bontša mafome ka mor'a ho feta tlhahlobo ea corrosion.

Nako ea poso: Feb-05-2024