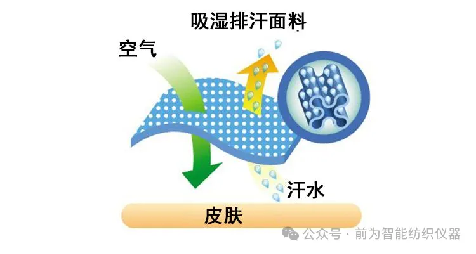

Njengoko imozulu isiya ishushu kwaye nobushushu bunyuka, iimpahla ziya zibhitya kwaye ziguge kancinci. Ngeli xesha, ukuphefumla kwempahla kubaluleke kakhulu! Isiqwenga sempahla esinamandla okuphefumla sinokukhupha ngokufanelekileyo ukubila emzimbeni, ngoko keukuphefumla kwelaphuihambelana ngokuthe ngqo nokuthuthuzela kwelaphu.

Ukusetyenziswa kwesakhono sokuphefumla kwishishini lelaphu

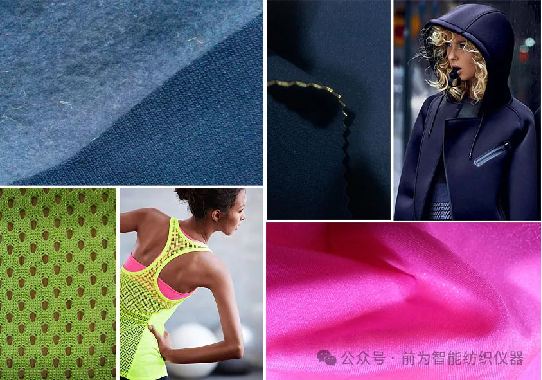

Ishishini lempahla: Isakhono sokuphefumla sesinye sezalathisi ezibalulekileyo zokuvavanya ubuntofontofo bempahla eluka. Ngokukodwa xa uyila iimpahla zezemidlalo zangaphandle, izihlangu zemidlalo kunye nezinye iimveliso, kuyafuneka ukuba uqinisekise ukuba zinokubonelela ngesakhono esilungileyo sokuphefumla ngovavanyo lokuphefumla ukufunxa ukufuma kunye nokubila. , Gcina isiphumo esomileyo.

Amalaphu asekhaya: iimveliso ezinje ngomandlalo, iikhethini, izigqubuthelo zefanitshala, njl.njl. Uvavanyo lokungena komoya lunokusetyenziswa ukumisela ukungenwa komoya kwezi mveliso kwaye emva koko kuvavanywe ukukhululeka kwazo kunye nokusebenza kwazo.

Izixhobo zonyango: Ilaphu zonyango elinje ngeengubo zotyando kunye nemaski kufuneka zibe namandla okuphefumla okuqinisekisa ukuba abasebenzi bezonyango banokuhlala bekhululekile kwindawo yokusebenza ixesha elide. Ngovavanyo lwesakhono sokuphefumla, ukusebenza kotshintshiselwano ngegesi kwimveliso kunokumiselwa ukuthintela usulelo lwebhaktiriya kunye nentsholongwane.

Izixhobo zemidlalo: Ezinye izixhobo zemidlalo ezifana nezihlangu zemidlalo, iminqwazi yezemidlalo, njl.

Ukusetyenziswa kobuchule bokuphefumla kwamanye amashishini

Izixhobo zangaphakathi zeemoto zangaphakathi: Qinisekisa ukunyanzeliswa komoya kunye nokuchasana komoya kwezixhobo zangaphakathi zemoto (ezifana ne-polyurethane, i-PVC, isikhumba, iingubo, amalaphu angalukwanga, njl. njl.).

Izinto zokwakha: Qinisekisa ukunyanzeliswa komoya kwizinto zokwakha (ezifana nelitye, ikhonkrithi, njl.) ukuvavanya amandla abo okuchaphazela umgangatho womoya ngaphakathi kwesakhiwo.

Izinto zokupakisha: Izinto ezininzi zokupakisha ezikhethekileyo (ezifana nokupakishwa okutsha, njl. njl.) kufuneka zibe neqondo elithile lokungena komoya ukuze kuqinisekiswe umgangatho wezinto zokupakisha.

Iimveliso ze-elektroniki: Amanye amacandelo eemveliso ze-elektroniki kufuneka abe nokuphefumla okulungileyo ukuqinisekisa ukusebenza okuqhelekileyo kwezixhobo zombane.

Ukuthelekiswa kweendlela ezahlukeneyo zovavanyo lokuphefumla

Ngoku, kukho imigangatho emininzi kunye neendlela zovavanyo lokuphefumla kwelaphu. Oku kulandelayo kukuzisela imigangatho yovavanyo kunye nothelekiso lokungena komoya kwamalaphu asetyenziswa ngokuqhelekileyo ekhaya nakwamanye amazwe. Le migangatho ivela kumazwe ahlukeneyo okanye imibutho, njenge-ISO, i-GB, i-BS, i-ASTM, njl njl. njengendlela yokuhamba komoya, indlela yokuhambisa umphunga wamanzi, njl.

1.ISO 9073-15 ISO 9237

Umda wesicelo: Ifanelekile kuvavanyo lokungena komoya kwizinto ezingalukwanga, ezifana nezixhobo zokucoca, izinto zokufakelwa kwe-thermal kunye nezinye iindawo. Umgaqo wovavanyo: Indlela yokuhamba komoya isetyenziselwa ukulinganisa ukuhamba kwegesi ngesampulu ukuvavanya ukusebenza kokuphefumla. Izixhobo zovavanyo: Umvavanyi wokungena komoya ubandakanya umthombo womoya, indawo yovavanyo, imitha yokuhamba kunye namanye amacandelo.

2.GB/T 5453 GB/T 24218.15

Umda wesicelo: Isetyenziselwa ukuvavanya ukusebenza kokuphefumla kwempahla, kubandakanya amalaphu, impahla, njl.

Umgaqo wovavanyo: Sebenzisa indlela yokuhamba komoya okanye indlela yokudlulisa umphunga wamanzi ukulinganisa isantya serhasi okanye umphunga wamanzi odlula kwisampulu ukuvavanya ukusebenza kokuphefumla.

Izixhobo zovavanyo: Iindlela ezahlukeneyo zovavanyo zinokufuna izixhobo ezahlukeneyo. Umzekelo, indlela yokuhamba komoya ifuna izixhobo zokuvavanya ukuphefumla, kwaye indlela yokuhambisa umphunga wamanzi ifuna izixhobo zokulawula ukufuma, njl.

3. BS 3424-16 BS 6F 100 3.13

Umda wesicelo: Isetyenziselwa ukuvavanya ukusebenza kokuphefumla kwamalaphu, njengamalaphu, impahla, njl.

Umgaqo wokuvavanya: indlela yokuhamba komoya okanye indlela yokudlulisa umphunga wamanzi isetyenziswa.

Izixhobo zovavanyo: Izixhobo ezahlukeneyo zinokufuneka ngokweendlela ezahlukeneyo zovavanyo. Umzekelo, indlela yokuhamba komoya ifuna izixhobo zokuvavanya ukuphefumla, kwaye indlela yokuhambisa umphunga wamanzi ifuna izixhobo zokulawula ukufuma, njl.

4. I-ASTM D737

Ububanzi besicelo: Isetyenziswa ikakhulu ukuvavanya ukusebenza kokuphefumla kwamalaphu.

Umgaqo wovavanyo: Indlela yokuhamba komoya isetyenziselwa ukulinganisa ukuhamba kwegesi ngesampulu ukuvavanya ukusebenza kokuphefumla.

Izixhobo zovavanyo: Umvavanyi wokungena komoya ubandakanya umthombo womoya, ukulungiswa kovavanyo, imitha yokuhamba, njl.

5. JIS L1096 Into 8.26 Indlela C

Ububanzi besicelo: Isetyenziswa kakhulu kwishishini lelaphu laseJapan, ikakhulu elisetyenziselwa ukuvavanya ukusebenza kokuphefumla kwempahla.

Umgaqo wovavanyo: Indlela yokuhamba komoya isetyenziselwa ukulinganisa ukuphefumla kwamalaphu.

Izixhobo zovavanyo: Umvavanyi wokungena komoya ubandakanya umthombo womoya, ukulungiswa kovavanyo, imitha yokuhamba, njl.

Phakathi kwazo, iindlela ezimbini eziqhelekileyo, i-ISO 9237 kunye ne-ASTM D737, zisetyenziswa ngokubanzi. I-GB/T 5453-1997 Lo mgangatho usebenza kwiintlobo ngeentlobo zamalaphu alukiweyo, kubandakanywa amalaphu emizi-mveliso, amalaphu angalukwanga kunye nezinye iimveliso ezilukiweyo eziphefumlayo. Ngexesha lovavanyo, amalaphu empahla kunye neendwangu zemizi-mveliso zahlulwa ngobuchule ngamathontsi oxinzelelo ahlukeneyo. Ukuhla koxinzelelo lwamalaphu empahla yayiyi-100Pa, kwaye ukuhla koxinzelelo lwamalaphu eshishini kwakuyi-200Pa. Kwi-GB/T5453-1985 "Iindlela zoVavanyo lweFabric Breath-ability Test", ukunyanzeliswa komoya (kubhekisa kumthamo womoya ohamba kwindawo yeyunithi yelaphu ngexesha leyunithi phantsi koxinzelelo oluchaziweyo kumacala omabini elaphu) isetyenziselwa ukulinganisa ukufikeleleka komoya kwelaphu. Umgangatho ohlaziyiweyo we-GB / T 5453-1997 usebenzisa i-air permeability (ebhekisa kwisantya sokuhamba komoya esidlula ngokuthe nkqo kwisampulu phantsi kwendawo yesampulu echaziweyo, ukuhla koxinzelelo kunye neemeko zexesha) ukuvakalisa ukunyanzeliswa komoya kwelaphu.

I-ASTM D737 yahlukile kule migangatho ingasentla ngokoluhlu lwesicelo, ubushushu kunye nokufuma, indawo yovavanyo, umahluko woxinzelelo, njl.njl. Kuthathelwa ingqalelo eyona meko yorhwebo olulaphu yokungenisa nokuthumela ngaphandle, kucwangciswe ukuba kusetyenziswe iisampuli ezahlukeneyo ukuthelekisa nokuxoxa nge ubushushu obuthile kunye nokufuma, indawo yovavanyo, umahluko woxinzelelo kunye nezinye iimeko ze-ISO 9237 kunye ne-ASTM D737, khetha ukusetyenziswa kunye neemeko ezimeleyo, kwaye useke imigangatho yoShishino efanelekileyo yorhwebo lokungenisa nokuthumela ngaphandle.

Uthelekiso lweziphumo zovavanyo

Iziphumo zokuphefumla ngelaphu zinxulumene ngokusondeleyo kwindlela yokuvavanya esetyenziswayo. Phakathi kweziphumo zovavanyo ezifunyenwe kusetyenziswa imigangatho yeendlela zokuvavanya ezahlukeneyo ezine: ISO 9237, GB / T 5453, ASTM D 737 kunye ne-JIS L 1096: ukunyanzeliswa komoya kuvavanywa ngokwe-GB / T 5453 kunye ne-ISO 9237 iyafana; ngokuhambelana ne-GB/T5453 (ISO 9237) ) Ukuvavanywa komoya okuvavanywa kuncinci; ukungenwa komoya okuvavanywa ngokweJIS L1096 yeyona inkulu; Ukungena komoya okuvavanywa ngokwe-ASTM D737 kuphakathi. Xa indawo yokuvavanya ihlala ingatshintshi, ukunyuka komoya kuyanda njengoko ukunyuka kwengcinezelo kunyuka, okuhambelana nokunyuka koxinzelelo lokunyusa amaninzi. Isishwankathelo, kuphela ngokukhetha iindlela ezifanelekileyo zokuvavanya ngokusekwe kwiimpawu zemveliso apho ukuphefumla kwamalaphu kunokuvavanywa ngokuchanekileyo.

Inkcazo ecacileyo yamanyathelo ovavanyo (ukuthatha i-GB / T 24218-15 njengomzekelo)

Iisampulu imiselwa ngokusekelwe kwimigangatho yemveliso okanye ukubonisana namaqela afanelekileyo. Kwizixhobo zokuvavanya ezinokuvavanya ngokuthe ngqo amalaphu amakhulu angalukwanga, ubuncinci iinxalenye ezi-5 zelaphu elingalukwanga likhulu linokukhethwa ngokungenamkhethe njengeisampulu zovavanyo; kwizixhobo zokuvavanya ezingakwazi ukuvavanya iisampuli ezinkulu, i-mold yokusika okanye i-template ingasetyenziswa (Sika ubuncinane iisampuli ze-5 ze-100mmX100 mm ubukhulu).

Beka isampuli ukusuka kwindawo eqhelekileyo kwindawo eqhelekileyo ye-atmospheric ehambelana ne-GB / T6529 kwaye ulungelelanise ukufuma kwi-equilibrium.

Bamba umphetho wesampulu ukunqanda ukutshintsha imeko yendalo yendawo yovavanyo engaphothiweyo.

Beka i-specimen kwintloko yokuvavanya kwaye uyilungise nge-clamping system ukukhusela ukuphazamiseka kwe-specimen okanye ukuvuza kwegesi edge ngexesha lovavanyo. Xa kukho umahluko kwi-permeability yomoya phakathi kwamacala angaphambili nangasemva kwisampuli, icala lokuvavanya kufuneka liphawulwe kwingxelo yovavanyo. Kwimifuziselo egqunyiweyo, beka umfuziselo ngecala eligqunyiweyo ezantsi (ukubhekisa kwicala elinoxinzelelo oluphantsi) ukunqanda ukuvuza kwerhasi.

Vula ipompo ye-vacuum kwaye ulungelelanise izinga lokuhamba komoya kuze kube yilapho umlinganiselo woxinzelelo ofunekayo ufikeleleke, oko kukuthi, i-100Pa, 125Pa okanye i-200Pa. Kwezinye izixhobo ezitsha, ixabiso loxinzelelo lovavanyo likhethwe kwangaphambili ngedijithali, kwaye umehluko woxinzelelo kumacala omabini e-aperture yokulinganisa uboniswa ngedijithali kwiyunithi yokuvavanya ekhethiweyo ukuququzelela ukufunda ngokuthe ngqo.

Ukuba igeyiji yoxinzelelo isetyenzisiwe, linda de ixabiso loxinzelelo olufunekayo lizinzile uze ufunde ixabiso lokungena komoya kwiilitha kwisikwere sesentimitha sesekondi [L/(cm·s)].

Ixesha lokuposa: May-06-2024