Iiseramikhi ezisetyenziswa mihla le zidla ngokubhekisa kwizinto zobomi bemihla ngemihla zabantu, njengezinto zetafile, iiseti zeti, iiseti zewayini okanye ezinye izitya. Ngenxa yemfuno enkulu yemarike, njengomhloli, maninzi amathuba okudibana neemveliso ezinjalo. Namhlanje, ndiza kubelana nawe ngolwazi malunga nokuhlolwa kweeseramikhi ezisetyenziswa mihla le.

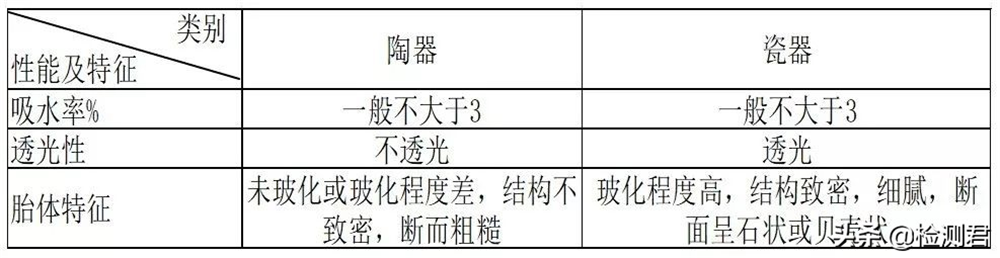

Umahluko phakathi kwePottery kunye nePorcelain

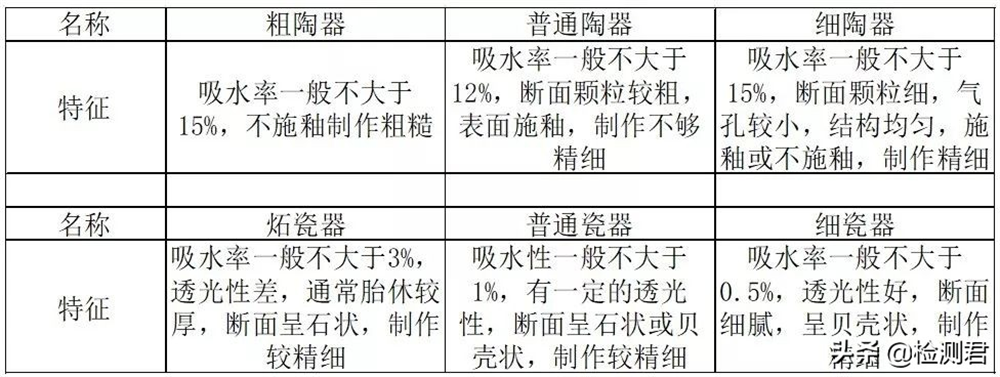

Umahluko phakathi kweentlobo ezahlukeneyo zeeramics

Ukuhlolwa kokupakishwa

Okokuqala, uhlolo lokupakisha kufuneka lwenziwe ngokwesivumelwano esithile esisayinwe ngamaqela omabini. Ukupakishwa kwangaphandle kufuneka kuqiniswe, kwaye i-internal lining kufuneka yenziwe ngezinto ezikhuselayo; iindawo zemveliso, ezifana netiyi kunye nesivalo, kufuneka zohlulwe ngephepha elithambileyo. Ngaphandle kwebhokisi yokupakisha (ibhasikithi), kufuneka kubekho iimpawu "zezinto ezibuthathaka" kunye "nezinto ezingenakunyakama".

Emva kokukhupha, kufuneka ukhangele ukuba kukho nawuphi na umonakalo kunye nenani leeqhekeza lifutshane, nokuba igama lemveliso kunye neenkcukacha zemodeli zihambelana nesivumelwano. I-porcelain efanelekileyo kufuneka ihlolisise ukuphelela kwayo, njengokuba inani elipheleleyo le-porcelain tableware kwisethi epheleleyo (eyaziwa ngokuba zingaphi iintloko) ichanekile.

Ukuhlolwa kwesiphene sembonakalo

1. Ukuguqulwa: kubhekiselele kwimilo yemveliso engahambelani noyilo oluchaziweyo.

2. Umlomo ogoso kunye nomqheba wendlebe: Umphakamo womlomo kunye nesiqheba sendlebe akukhululekanga kwaye ugobile.

3. Iqhakuva: Ibhekisa kwithumba elinyusiweyo elifana nemilo eqinileyo yomzimba oqaqambileyo.

4. Iqamza: libhekisa kwiqamza elinomgongxo eliphakanyiswe kumzimba oqaqambileyo.

5. I-Slag: Ibhekisa kwiziphene ezibangelwa ludaka oluseleyo kunye nentsalela ye-glaze kwindawo engenanto engakhange isuswe.

6. Ukungabikho kodaka: kubhekisela kwinto yokuba umzimba oluhlaza awuphelelanga.

7. Iqamza elikhazimlayo: libhekisa kumaqamza amancinci kumphezulu weglaze.

8. I-blister edge: ibhekisela kuthotho lwamaqamza amancinci avela kumda womlomo wemveliso.

9. Ugqabhuko-dubulo olungenanto: Kubhekiselele ekuxovuleni kwendawo okubangelwa lulawulo olungafanelekanga lokufuma phambi kokuba okungenanto kungene eziko.

10. I-Fried glaze: ibhekisela kwinto yokuqhekeka kwi-glazed surface yemveliso.

11. Ukuqhekeka: kubhekiselele kwiziphene ze-striate ezenziwe ngokuqhekeka kwee-blanks kunye ne-glazes, ezahlulahlulwe zaba ziindidi ezintathu. Eyokuqala yintanda egqunywe ngumkhenkce, ebizwa ngokuba yi-yin crack. Okwesibini kukuba i-glaze iyaqhekeka kwaye umzimba awuqhekeki, oku kubizwa ngokuba yi-glaze cracking. Okwesithathu kukuba zombini umzimba kunye ne-glaze iyaqhekeka, ebizwa ngokuba yi-crack of both body and glaze.

12. Umngxuma otyhidiweyo: ubhekisa kumngxuma oveliswe kukunyibilika kwezinto ezixubeneyo ngexesha lokudubula.

13. Amabala: abhekisa kumabala anemibala kumphezulu wempahla, eyaziwa ngokuba ngamabala entsimbi.

14. Imingxunya: ibhekisa kwimingxuma emincinci (okanye imingxuma yehagu enamehlo amdaka, imingxunya) ekhoyo kumphezulu omenyezelayo.

15. I-Slag falling: ibhekisela kumlotha we-saggar kunye nezinye iinqununu ze-slag ezinamathele kumphezulu oqaqambileyo wemveliso.

16. Umda ongezantsi we-slag onamathele: ubhekisela kwiincinci ezincinci ze-slag ezinamathele kumda weenyawo zemveliso.

17. Inqaku lenaliti: umkhondo oshiywe yinkxaso kwimveliso.

18. Isiva esincangathi: isiphene esenziwe kukuhlangana phakathi komzimba oluhlaza kunye nento yasemzini ngexesha lokudubula.

19. Iliva lomlilo: Umphezulu omdaka orhabaxa obangelwa luthuthu lwempukane edangatyeni.

20. Ukunqongophala kweglaze: Kubhekisa ekuthotyweni kwenxalenye yemveliso.

I-21, i-orange glaze: ibhekisela kwi-glaze efana ne-orenji peel.

22. Umsonto omenyezelayo wodaka: ubhekisa kwinto efana nestrand yomzimba oluhlaza kunye nomphezulu omenyezelayo unyuswe ngokuyinxenye.

23. Icwecwe elicwebezelayo: Ibhekisa kumaleko akhazimlayo kumphezulu wemveliso, owenza umfanekiso wokuba umphezulu weglaze awuqaqambi.

24. Umbala ongcolileyo: ubhekisela ekubonakaleni kwemibala e-variegated ebusweni bemveliso engafanele ibe khona.

25. Umbala ongalunganga: ubhekiselele kumbala ongalinganiyo wepateni efanayo okanye isenzeko sokungabikho kokukhanya okubangelwa kukungabikho komlilo.

26. Ukungabikho kwemigca: kubhekiselele kwiziphene zemigca kunye nemiphetho ehlotshiswe ngemigca.

27. Ukunqongophala komfanekiso: Kubhekisa kwisenzeko somfanekiso ongaphelelanga kunye nombala ongachanekanga.

28. Intyatyambo ebhakiweyo i-glaze encangathi: ibhekisa kumabala anemibala kunye nomonakalo we-glaze ebusweni obukhazimlayo bemveliso ngexesha lokubhaka.

29. Inyawo ezimdaka ezisezantsi: Ibhekisa kobunye ukungcola okuncamathele kumazantsi eenyawo kunye nokujika kombala.

30. Umahluko wombala wodaka oludibeneyo lomlomo kunye nendlebe: Umbala wodaka oluhlangeneyo lomlomo kunye nendlebe aluhambelani nemveliso ngokwayo.

31. I-Gypsum engcolileyo: ibhekisela kwi-heterochromatic phenomenon yomzimba oluhlaza ngenxa yokubambelela kwe-gypsum.

32. Igolide eluhlaza: Isiganeko esiluhlaza okwesibhakabhaka esibangelwa yintsimbi ebhityileyo kakhulu.

33. Ukutshaya: kubhekiselele kwinkangeleko yengwevu, emnyama kunye nemdaka ngenxalenye okanye yonke imveliso.

34. Yin yellow: ibhekisa kwinxenye okanye ngokupheleleyo yellowing yemveliso.

35. Imikrwelo ye-glaze: ibhekisa kwi-phenomenon ye-streaks kunye nokulahleka kwenxalenye yegloss kwindawo ekhazimlayo yempahla.

36. I-Bump: ibhekisa kwimpembelelo engaphelelanga okanye ukonakalisa kwempahla, okwakwaziwa njengokwenzakala kanzima.

37. Ukuqengqeleka komkhondo: kubhekiselele kwimilo ye-arc eveliswe ngokurola okanye ukucinezela imela.

38. Ipatheni ye-Wavy: ibhekisela kwipatheni ye-wavy evezwe yi-glaze engalinganiyo yemveliso.

Uvavanyo lwesalathiso somzimba kunye neekhemikhali

1. Uvavanyo lokufunxwa kwamanzi kwi-ceramics yokusetyenziswa kwemihla ngemihla

2. Ukuhlolwa kokuzinza kwe-thermal yeekeramics zasekhaya

3. Ubumhlophe beeseramics zemihla ngemihla

4. Ukuhlolwa kwelothe kunye nokuchithwa kwecadmium yeeseramikhi ezisetyenziswa mihla le.

Ukuhlolwa kwePorcelain yemihla ngemihla

1. Iinkcukacha zeporcelain ecocekileyo yokusetyenziswa kwansuku zonke

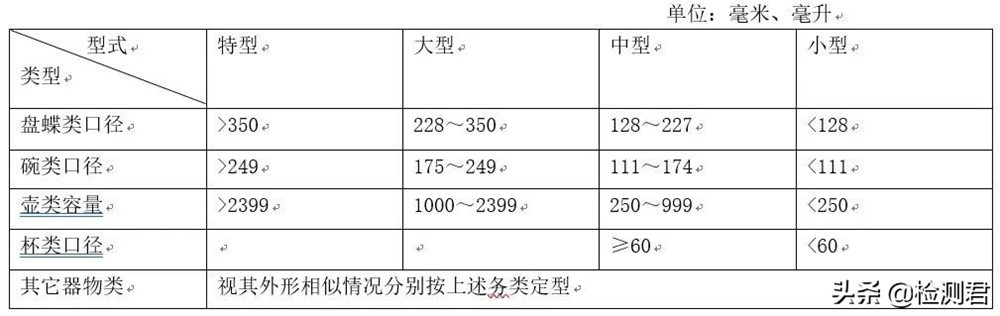

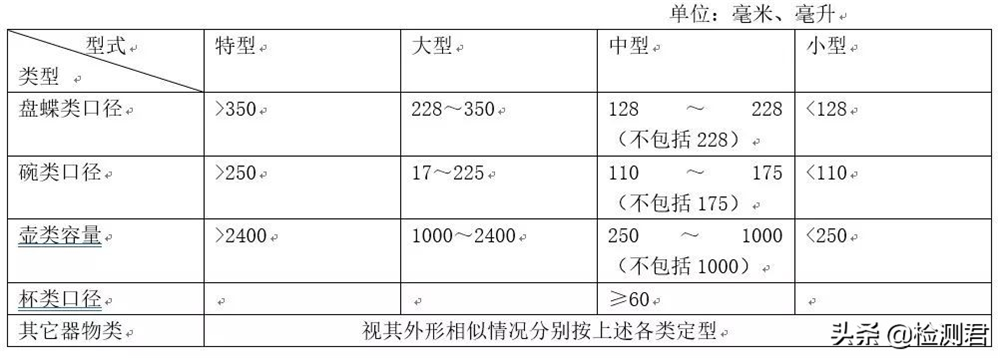

Iimpawu zemveliso zohlulwe zibe zikhethekileyo, ezinkulu, eziphakathi, nezincinci. Umxholo othile ubonisiwe kwitheyibhile:

2. Ukuhlelwa kweporcelain efanelekileyo yokusetyenziswa kwansuku zonke

I-porcelain yemihla ngemihla yohlulwe ibe ngamabakala amane ngokomgangatho wenkangeleko, kwaye iimfuno ezithile zezi zilandelayo:

Akukho ngaphezu kwe-4 iintlobo zeziphene kwimveliso nganye kwiimveliso zodidi lokuqala;

Iimveliso zodidi lwesibini aziyi kudlula iziphene ezi-5 ngemveliso nganye;

Imveliso nganye yodidi lwesithathu ayisayi kuba ngaphezu kweentlobo ezi-6 zeziphene;

Imveliso nganye yeBanga lesi-4 ayisayi kuba neentlobo ezingaphezu kwesi-7 zeziphene;

Ukongeza, ngokomgangatho, kuyafuneka:

1. Izinga lokufunxa kwamanzi akufanele lidlule kwi-0.5%.

2. Iimfuno zokuzinza kwe-thermal, ukusuka kwi-200 ℃ ukuya kwi-20 ℃ yamanzi, ukutshintshwa kobushushu akuyi kuqhekeza kanye (i-bone china ayikhawulelwanga).

3. Ubumhlophe be-porcelain emhlophe abuyi kuba ngaphantsi kwe-65%, ngaphandle kweemveliso ezine-blue glaze kunye nesitayela esikhethekileyo sombala.

4. Ukutshatyalaliswa kwesikhokelo kwindawo yoqhagamshelwano kunye nokutya akukho ngaphezu kwe-7PPM, kwaye ukuchithwa kwe-cadmium akukho ngaphezu kwe-0.5PPM.

5. Ukunyamezela kwe-diameter. Ububanzi obulingana okanye ngaphezulu kwe-60 mm, vumela ukusuka +1.5% ukuya kwi-1%; kububanzi obungaphantsi kwe-60 mm, vumela i-±2%.

6. Xa ibhodwe lithambekele kwii-degrees ezingama-70, isiciko akufanele siwe. Xa isiciko sihanjiswa kwicala elinye, umgama phakathi kwesivalo kunye ne-spout akufanele udlule i-3 mm. Umlomo we-spout akufanele ube ngaphantsi kwe-3 mm ukusuka kwi-spout.

7. Umbala we-glaze kunye nombala wesithombe seseti yeemveliso kufuneka zifanane ngokusisiseko, kunye neenkcukacha kunye nobukhulu kufuneka bulingane.

8. Akukho glaze yokuqhotsa, ukubetha, ukuqhekeka kunye neziphene zokuvuza zivumelekile.

Ukuhlolwa kodongwe olucolekileyo lwemihla ngemihla

1. Iinkcukacha zomdongwe ocolekileyo wemihla ngemihla

Iimpawu zemveliso zohlulwe zibe zikhethekileyo, ezinkulu, eziphakathi, nezincinci. Umxholo othile ubonisiwe kwitheyibhile

2. Ukuhlelwa kwezitya zomdongwe zemihla ngemihla

Udongwe olucolekileyo lwemihla ngemihla lwahlulahlulwe lwangamabakala amathathu ngokomgangatho wenkangeleko, iimfuno ezithile zezi zilandelayo:

Iimveliso zodidi lokuqala aziyi kudlula iziphene ezi-5 ngemveliso nganye;

Iimveliso zodidi lwesibini aziyi kudlula iziphene ezi-6 ngemveliso nganye;

Imveliso nganye yodidi lwesithathu ayisayi kuba ngaphezu kweentlobo ezisi-8 zeziphene;

Ukongeza, umgangatho umisela ukuba:

1. Umgangatho wetayara uxinene, kwaye izinga lokufunxa amanzi alidluli i-15%.

2. Umphezulu we-glaze ugudile kwaye umbala uhlambulukile.

3. Iimfuno zokuzinza kwe-thermal, ukusuka kwi-200 ℃ ukuya kwi-20 ℃ yamanzi, ukutshintshiselana kobushushu akuyi kuqhekeka kanye.

4. Imveliso kufuneka ibe tyaba kwaye izinzile xa ibekwe kwindawo ethe tyaba.

5. Ukunyamezela kwedayimitha yemveliso, ukunyamezela ku- + 1.5% ukuya kwi-1% kububanzi obukhulu okanye obulingana no-60 mm, kwaye ukunyamezela ngu-± 2% kububanzi obungaphantsi kwe-60 mm.

6. Ubungakanani besiciko kunye nomlomo wazo zonke iimveliso ezigqunyiweyo kufuneka zifaneleke.

7. Imveliso ayivumelekanga ukuba ibe ne-frying glaze, i-bumping, i-cracking kunye ne-leakge defects, kwaye akukho zibhubhu zokuvula kunye neengqungquthela ekupheleni komlomo kunye neekona.

8. Umbala we-glaze, umfanekiso kunye ne-gloss yesethi epheleleyo yeemveliso kufuneka ibe yinto efanayo, kunye neenkcukacha kunye nobukhulu kufuneka bulingane.

9. Ukuchithwa kwe-lead kwindawo yokudibanisa kunye nokutya akukho ngaphezu kwe-7PPM, kwaye ukuchithwa kwe-cadmium akukho ngaphezu kwe-0.5PPM.

Ixesha lokuposa: Aug-16-2022