Ikhadibhodi efakwe amazinki yikhathoni eyenziwe ngokufa, ukusika, ukubethelela okanye ukuncamathelisa.

Iibhokisi zentsimbi zezona mveliso zisetyenziswa kakhulu zokupakisha, kwaye ukusetyenziswa kwazo bekuhlala kukuqala phakathi kweemveliso ezahlukeneyo zokupakisha. Kubandakanywa iibhokisi zeplastiki ze-calcium.

Ngaphezulu kwesiqingatha senkulungwane, iibhokisi zamacangci ziye zatshintsha ngokuthe ngcembe iibhokisi zeplanga kunye nezinye izikhongozeli zokupakisha zezothutho kunye nokusebenza kwazo okuphezulu kunye nokusebenza kakuhle kokusebenza, zibe yeyona nto iphambili yokupakishwa kwezothutho.

Ukongeza ekukhuseleni iimpahla kunye nokuququzelela ukugcinwa kunye nokuthutha, ikwadlala indima ekuhombiseni nasekukhuthazeni iimpahla.

Iibhokisi ze-corrugated ziluhlaza kunye neemveliso ezihambelana nokusingqongileyo, ezilungele ukukhuselwa kwendalo kwaye zilungele ukulayisha, ukuthuthwa kunye nokuthutha.

Ibhokisi ebotshiweyo yimveliso eqhelekileyo yokupakishwa kwephepha engenakwahlulwa kubomi bethu kunye nemveliso. Ukuvavanya izalathisi zamandla ezahlukeneyo likhonkco elibaluleke kakhulu kwimveliso kwaye kubaluleke kakhulu ekuqinisekiseni umgangatho wemveliso kunye nokusebenza. Ukuvelisa iimveliso zeekhathoni ezifanelekileyo, iibhokisi zamalahle kufuneka zihlolwe ukuze inkqubo yokuveliswa kweebhokisi zamalahle ikwazi ukulawulwa ngokufanelekileyo.

01.Umgangatho wembonakalo

Iibhokisi ezifanelekayo zifuna iipatheni ezicacileyo eziprintiweyo kunye nokubhala, ngaphandle kwemigca ephukileyo okanye imigca engekhoyo; umbala wepateni uhambelana, uqaqambile kwaye uqaqambile, kwaye impazamo yendawo yoshicilelo incinci. Impazamo yeebhokisi ezinkulu zingaphakathi kwe-7mm, kwaye impazamo yeebhokisi ezincinci ingaphakathi kwe-4mm. Umgangatho ongaphezulu kufuneka uphelele, ngaphandle komonakalo okanye amabala, akufanele kubekho imingxuma ejikeleze ibhokisi, kwaye akufanele kubekho izikhewu xa izivalo zivaliwe. Ukongeza, iindawo ezidityanisiweyo zekhabhinethi nazo ziyafuneka ukuba zilungelelaniswe, zibe nemiphetho ecocekileyo kwaye azikho iikona ezidlulayo.

02.Umxholo wokufuma

Oko kubizwa ngokuba kukunyakama kubhekiselele kwisiqulatho sokufuma kwisiseko sephepha okanye ikhadibhodi, esichazwa njengepesenti. Umxholo wobumanzi unempembelelo enkulu kumandla webhokisi yebhokisi. Yenye yezinto ezintathu ezinkulu zokuhlola isiphene kwibhokisi. Iphepha lesiseko elityebileyo linokumelana noxinzelelo oluthile, ukuxhathisa, ukuxhathisa kokugqobhoza kunye nokuxhathisa ukusonga. Ukuba isiqulatho sokufuma siphezulu kakhulu, iphepha liya kubonakala lithambile, libe nokuqina okulambathayo, kwaye libe ne-corrugating engalunganga kunye nomgangatho wokubopha. Ukuba umgangatho wokufuma uphantsi kakhulu, iphepha liya kuba brittle kakhulu, lithande ukuqhekeka ngexesha le-corrugation, kwaye liya kuba nokuxhathisa ukusonga. Ukuba umahluko kumxholo wokufuma phakathi kwephepha eligutyungelweyo kunye nephepha lebhokisi lilikhulu kakhulu, ikhadibhodi esontiweyo ecutshungulwa ngumatshini onecala elinye iya kugoqa ngokulula, kwaye ukudumba kunye ne-degumming kuya kwenzeka xa kulayitwa. Ukuba i-carton ebunjiweyo ithatha umswakama ngexesha lokugcinwa, amandla ebhokisi aya kuncitshiswa kakhulu, echaphazela ukusetyenziswa kwayo.

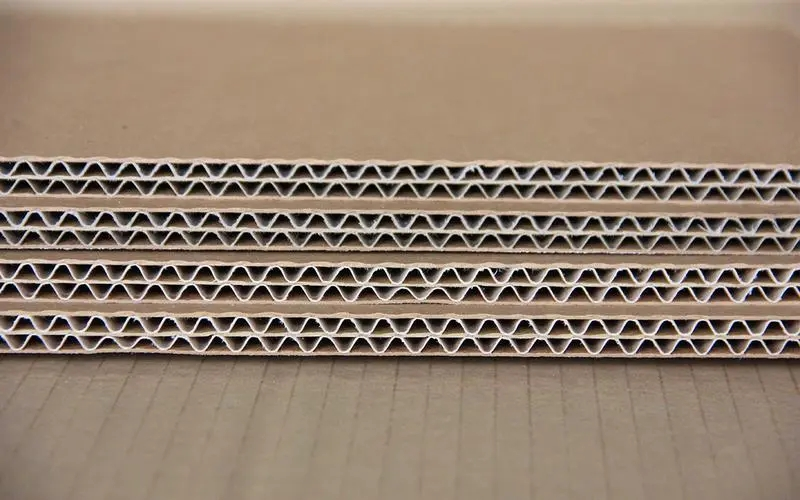

03. Ubukhulu bekhadibhodi

Kukho izizathu ezininzi ezichaphazela ubukhulu bekhadibhodi. Ukuba ubukhulu bekhadibhodi eboshiweyo buncinci, amandla ayo oxinzelelo, amandla okubhoboza kunye namandla oxinzelelo aya kuncitshiswa ngokufanelekileyo. Ikhadibhodi enezinki ineentlobo ezahlukeneyo zembande kunye nobukhulu obahlukeneyo. Iilabhoratri zidla ngokusebenzisa iimitha ezingqindilili zekhadibhodi ukuze zibone ubukhulu bekhadibhodi.

04.Ubunzima bebhokisi

Ukulinganisa ubunzima beebhokisi kwakhona ngumsebenzi obalulekileyo kwiinkampani zeekhathoni. Iinkampani zeekhathoni kufuneka zilinganise ubunzima beekhathoni ngexesha lezibhengezo zokuthumela ngaphandle naxa zibala iziphumo. Ukongeza, ngamanye amaxesha abathengi baya kusebenzisa iintsimbi zebhokisi njengomnye wemigangatho yokuhlolwa kwezinto zebhokisi. Nye.

05. Amandla oxinzelelo lwe-Edge

Ubungakanani boxinzelelo ukuba isampulu yobubanzi obuthile inokumelana nobude beyunithi nganye ibizwa ngokuba yi-edge pressure strength. Amandla oxinzelelo lomphetho wekhathoni enamazinki abhekiselele ekukwazini ukumelana noxinzelelo olunxuseneyo necala le-corrugation. Amandla okutyumza umsesane wephepha lesiseko kunye namandla okudibanisa amakhadibhodi amisela amandla okutyumza komphetho wekhadibhodi ukuya kumlinganiselo omkhulu. Iziphumo zibonakaliswa njengexabiso eliphantsi.

06. Amandla acinezelayo

Amandla oxinzelelo lwebhokisi ye-corrugated ibhekisela kumthwalo ophezulu kunye ne-deformation enokumelana nayo kuze kube yilapho ibhokisi yonakaliswe xa umatshini wokuvavanya uxinzelelo usebenzisa uxinzelelo oluguquguqukayo ngokulinganayo. Ngethuba lenkqubo yonke yokunyanzeliswa kwengcinezelo yebhokisi, iimbombo ezine zigxininiswe kakhulu, zibalelwa malunga nesibini kwisithathu samandla onke. Ngoko ke, ngexesha lenkqubo yokuvelisa, kufuneka sizame ukunciphisa umonakalo kwi-corrugations ejikeleze iikona ezine zebhokisi. Amandla oxinzelelo lweekhathoni ahlulwe kwixabiso elisebenzayo kunye nexabiso lokugqibela. Umgangatho ongcono wekhathoni, uphezulu ixabiso elisebenzayo lamandla oxinzelelo, kunye nokuncinci ukutenxa phakathi kwexabiso elisebenzayo kunye nexabiso lokugqibela.

07. Amandla okubambelela

Iqondo lokubambelela phakathi kwephepha eliphezulu lekhadibhodi, iphepha le-lining, i-core paper kunye ne-corrugated corrugated force, kunye nowona mandla aphezulu okuxobula anokumelana nobude beyunithi ethile, ibizwa ngokuba ngamandla okunamathela kwikhadibhodi edibeneyo, emele amandla ikhadibhodi yamazinki. ukuqina. Umgangatho, ifomula, izixhobo, inkqubo yokusebenza kunye nezinye izinto ezincamathelayo zimisela amandla okuncamathela ekhadibhodi, kwaye amandla okuncamathela ekhadibhodi achaphazela kakhulu ukuxhathisa koxinzelelo kunye nokuqina kwebhokisi. Amandla okugqabhuka kunye namandla okugqobhoza.

08.Ukusonga ukunyamezela

Njengesingxobo sokupakisha, isiciko sebhokisi kufuneka sivulwe rhoqo, nto leyo efuna ukuba ikhadibhodi ibe nokumelana okuthile nokusonga.

Iipropathi eziludaka zebhokisi yebhokisi kunye nephepha lebhodi emhlophe, umxholo wokufuma, ukuqina, ubude befayibha kunye nokuqina kokuqina kwesiseko sephepha, kunye nexesha lokugcinwa kunye nobushushu bephepha lesiseko, misela ubukhulu becala ukuxhathisa ukusonga kwesiseko sephepha. . Oku kugqiba ukuxhathisa ukusonga kwebhokisi.

09. Umsebenzi oguqukayo wekhathoni

Ukupakishwa kwezinto ezithile ezinje ngeseramiki, iimveliso zeglasi, izixhobo ze-elektroniki, njl. njl., ukusebenza kwebhokisi yeebhokisi zeempahla kufuneka kwakhona kuvavanywe, oko kukuthi, iimvavanyo ezinje ngothutho olufanisiweyo, ukulayishwa kunye nokukhulula, ukungcangcazela, kunye amathontsi aqhutywa ukuvavanya ukusebenza kweebhokisi.

Udidi A olungafanelekanga: Ikhathoni ayinakuhlangabezana nomsebenzi wokukhusela okanye wokumakisha iziqulatho.

(1) Iintsimbi ziyahlukana.

(2) Imilinganiselo idlula uluhlu lwempazamo oluvumelekileyo.

(3) Umgangatho ungaphantsi kwexabiso elincinci elichaziweyo.

(4) Umgca we-indentation uphukile okanye umphezulu wephepha unqunywe.

5

(6) Iimpazamo zoshicilelo, iimpazamo zoshicilelo ezingaphelelanga okanye umbala kunye neepatheni.

(7) Ungcoliseko olubangelwa zizinto zangaphandle.

Udidi B alunakufaneleka: Ikhathoni ayisebenzi ngokupheleleyo okanye ineengxaki.

(1) I-seams ayibophekanga ngokupheleleyo, i-tape joints ayiphelelanga okanye i-joints ayibethelwanga ngokwaneleyo.

(2) Izithuba ezisikwe emacaleni ebhokisi.

(3) Iziqwenga zokugubungela azikwazi ukufakwa, kwaye i-gap inkulu kune-3mm.

(4) Ubumanzi bekhadibhodi bungaphezulu kwama-20% okanye ngaphantsi kwe-5%.

(5) Ibhokisi igotywe kwiindawo ezingafakwanga ngaphakathi.

(6) Ushicilelo olusebhokisini aluphelelanga okanye imizobo kunye nokubhaliweyo kumfiliba.

(7) Ibhokisi ayithathi manyathelo okuthintela ukutyibilika njengoko kufuneka.

Udidi C olungafanelekanga: Imbonakalo yebhokisi ihlwempuzekile, kodwa umsebenzi wayo awuchaphazeleki.

(1) Ukusika okanye ukusika iibhokisi zokufa kurhabaxa.

(2) Umphezulu wekhadibhodi unokungalingani okufana nokuhlamba, okuchaphazela umgangatho wemizobo eprintiweyo kunye nombhalo.

(3) Kukho iindawo zokungcoliseka kwindawo yebhokisi.

(4) Imikrwelo engekho nzulu okanye amanqaku akhutshiweyo.

Ixesha lokuposa: Mar-27-2024