Kukho iindidi ezininzi zefanitshala, njengefenitshala yomthi oqinileyo, ifenitshala yentsimbi ekhandiweyo, ifenitshala yeepaneli, njalo njalo. Izinto ezininzi zefenitshala zifuna ukuba abathengi bazihlanganisele ngokwabo emva kokuthenga. Ngoko ke, xa abahloli kufuneka bahlole ifenitshala edibeneyo, kufuneka badibanise ifenitshala kwisiza. Ngawaphi amanyathelo ezixhobo zokuqhawula kunye nokudibanisa ifanitshala, indlela yokusebenza kwindawo, kwaye ngawaphi amanyathelo okhuseleko.

1.Ubungakanani bokuhlolwa kwendibano yesiza

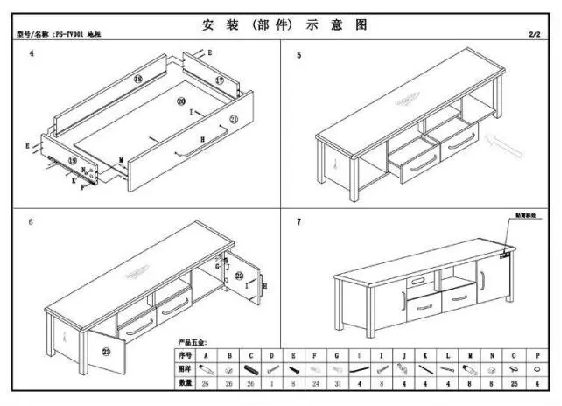

1) Umhloli kufuneka ahlanganise ngokuzimeleyo ubuncinane isethi enye yeemveliso ngokwencwadi yendibano. Ukuba ubungakanani bemveliso bukhulu kakhulu kwaye bufuna uncedo lwabasebenzi befektri, kuyimfuneko ukuqinisekisa ukuba ukudibanisa kunye neengxenye ezihambelanayo zifakwe kwaye ziqhutywe ngumhloli ngokwazo.

2) Indibano yezinye iimveliso inokugqityezelwa ngabasebenzi basefektri, kodwa kufuneka igqitywe phantsi kolawulo olupheleleyo lwendawo yomhloli. Kubalulekile ukuhlola yonke inkqubo yokuhlanganiswa kwemveliso, kunokuba ugxininise kwisiphumo sokugqibela sokuhlanganiswa. Ngoko ke, ngexesha lenkqubo yezixhobo, umhloli akakwazi ukushiya indawo yendibano, kwaye ubuninzi bezixhobo buxhomekeke kwiimfuno zokuhlola (WI).

2.Kwindawo yokuhlanganisa amanyathelo kunye nezilumkiso

1) Kwizixhobo zesayithi kufuneka zilandele ngokungqongqo imiyalelo yendibano ebonelelwe yimveliso. Ngexesha lenkqubo yendibano, khangela ukuba ngaba amanyathelo kwimiyalelo yendibano ichanekile, ingaba icandelo ngalinye lihlangabezana neemfuno zobugcisa, nokuba lihambelana ngokuqinileyo, nokuba indawo yomngxuma ichanekile, ingaba imveliso iqinile, nokuba ngaba izixhobo zangaphandle ziyafuneka (ngokubanzi akunjalo. kuvunyelwe, iimfuno ezithile zixhomekeke kwimiyalelo)

2) Ngaphambi kokuhlanganisana, kubalulekile ukuchonga inani lamacandelo emveliso, vula ibhokisi yekhadibhodi yokupakisha, ubeke iphakheji ye-hardware kwindawo eyahlukileyo kwaye uyibale ukuze ugweme ukulahlekelwa okanye ukudibanisa kunye nezixhobo ezivela kwezinye iimveliso.

3)Okokuqala, khangela ukuba inani kunye nobukhulu bamacandelo buhambelana nobuninzi obubonakaliswe kwincwadana. Ebudeni bendibano, kulumkele ukutshintsha iindawo ezingafanelekanga.

4) Funda ngokucokisekileyo incwadana yendibano, okokuqala ukwahlula amacandelo aphambili ngokulandelelana kwendibano, kwaye u tyelele iibhodi ngokwahlukileyo ukuze ufanise ukufakela. Kungcono ukuthatha iifoto zezi bhodi ngokufanayo.

I-5) Lungiselela izixhobo zokufakela ezifana ne-screwdrivers, i-wrenches, njl., kwaye ulandele ngokungqongqo amanyathelo endibano kwincwadana yokudibanisa imveliso ngexesha lenkqubo yokuhlanganisa. Abahloli kufuneka bahlawule ingqwalasela eyodwa: abasebenzi basefektri bahlala bethembele kumava ngexesha lokudibanisa kwaye basilele ukulandela ngokupheleleyo amanyathelo akwincwadana yezixhobo. Esi senzo asinakuqinisekisa ukuba ingaba incwadana yemigaqo yesixhobo ifanelekile kwaye iphelele na. Ukuba le meko ifunyenwe, kufuneka imiswe / ilungiswe ngokukhawuleza. Kungcono ukufakela iyunithi enye ngexesha, kwaye hayi iiyunithi ezininzi ngexesha elinye, ukuthintela ulongamelo olunganelanga.

6) Ngokubanzi, inkqubo yokuhlanganisa uninzi lweemveliso inokwahlulwa ngokwezigaba ezine:

Isinyathelo sokuqala kukwenza i-skeleton yemveliso. Ngethuba le nkqubo, ingqalelo kufuneka ihlawulwe ukuba ngaba imingxuma yokudibanisa i-skeleton ichanekile, ingaba ukufakwa kweebholiti kunye nezinye izinto zokubopha zihamba kakuhle, nokuba ngaba izixhumi zivaliwe, nokuba izithuba ze-skeleton zifana kwaye zihambelana.

Isinyathelo sesibini kukufaka amacandelo asisigxina aqinisa isakhiwo kwi-skeleton. Ngethuba le nkqubo, ingqwalasela kufuneka ihlawulwe kwizixhobo ze-hardware, ngakumbi izikrini, ezingafanele zilahleke. Zonke iinqununu kunye ne-fasteners kufuneka zibekwe kwisakhelo, kwaye imingxuma yokudibanisa kufuneka ihlolwe ukufaneleka. Kubalulekile ukuqaphela ukuba ukungahambi kakuhle kwe-screw hole kaninzi kwenzeka ngexesha le nkqubo.

Isinyathelo sesithathu kukufaka izixhobo ezikhokelayo okanye i-hinge edibeneyo ehambayo kwiindawo ezihambelanayo. Kubalulekile ukuba uqaphele ukuba amacandelo efenitshala anokuchithwa kwaye adityaniswe ngamaxesha amaninzi ngaphandle kwemiba yomonakalo. Kule nkqubo, ingqalelo kufuneka ihlawulwe ukuba ngaba ezi zixhobo zinemingxuma evulekileyo ye-screw okanye iindawo ezonakalisiweyo emva koxhumo olulodwa.

Inxalenye yesine kukufaka izinto ezincinci okanye ezihlobisayo okanye izixhobo. Ngexesha lale nkqubo, kufuneka kuqwalaselwe ukuba ubude be-screw buhlangabezana neemfuno, nokuba izixhobo zokuhombisa zinokuqiniswa ngokuqinileyo, nokuba indawo yomngxuma ifanelekile xa utshixa isikrufu, nokuba imveliso ayifanele ikrwelwe okanye izixhobo azifanele. khululeka.

Imibuzo ebuzwa qho

1. Ukungabikho kwamacandelo kwimveliso, ngokukodwa izixhobo ze-hardware kwiipakethe ezincinci

2. Isikhundla somngxuma asihlangabezani neemfuno, ingakumbi kubandakanywa indawo engafanelekanga yomngxuma wokudibanisa, umngxuma omncinci, umngxuma onzulu kakhulu okanye onzulu kakhulu, ukutenxa kwicala, njl.

3. Izimbobo ze-accessory ebhodini zizaliswe ngepeyinti, kwaye i-hardware ayikwazi ukufakwa kakuhle

4. Izixhobo ze-Hardware azikwazi ukutshixwa ngokuqinileyo, kwaye imveliso ayikhuselekanga

5. Xa utshixa izixhobo zehardware, iikhomponenti zinokonakala, ziqhekeke, okanye zonakaliswe

6. Iindawo ezihambayo ezisebenzayo azikwazi ukutyhala okanye ukutsalwa kakuhle

7. Izihlanganisi ezonakalisiweyo kunye ne-rust stains ebusweni bezixhobo ze-hardware

8. Izikhewu ezigqithisileyo okanye ezingalinganiyo phakathi kwamacandelo ngexesha lendibano

Iimfuno zomgangathokwayeiindlela zokuhlolakwiimveliso

1. Indlela yokuhlola

Umlinganiselo wesixhobo, uhlolo olubonakalayo, ukubamba ngesandla, kunye nokuhlolwa kweemveliso ngokweemfuno zobugcisa zendibano yemveliso kunye nobukhulu bomzobo kunye neemilo.

2. Umgama wokubona

Kufuneka ibe phantsi kokukhanya kwendalo okanye ukukhanya okuqikelelweyo kwendalo (umzekelo: isibane sefluorescent engama-40W), kunye noluhlu olubonakalayo lwe-700-1000mm.

3. Ugxininiso lokuhlolwa kwenkangeleko

1) I-welding, i-riveting, mortise kunye ne-tenon joints ezisetyenziselwa ukulungisa izinto akufanele zikhululeke.

I-2) Izikrufu kunye ne-hardware uxhulumaniso akufuneki lukhululeke

3) Umphezulu wezixhobo ze-hardware awunamikrwelo, i-plating (i-coating) umaleko uqinile, kwaye akukho kuxobulwa okanye ukurusa.

4) Amacandelo okuthwala umthwalo kunye neendawo ezihambayo akufuneki zibe nokuqhekeka, amaqhina, imingxuma yezinambuzane, okanye ezinye iziphene.

5) Iindawo ezihambayo kufuneka ziqiniswe kwaye zithembeke, zingawi ngokwazo, kwaye kufuneka ziguquguquke kwaye zisebenziseke lula.

6) Izixhobo zetsimbi akufanele zibe neentanda okanye izibazi

I-7) Akufuneki kubekho i-desoldering, i-welding virtual, okanye ukungena kwe-welding kwindawo ye-welding

I-8) Amalungu adibeneyo kufuneka angabikho kwiipores, i-weld nodules, kunye ne-spatter

I-9) Amacandelo ahlanjululweyo kufuneka ahlanjululwe kakuhle ngaphandle kweempawu zesando

10) Ukwaleka kufuneka kungabikho ukutsha, amaqamza, imingxunya, iintanda, iintsimbi, imikrwelo.

11) Ukugquma kwamalungu esinyithi akufuneki kungabikho ngezantsi, ukungalingani, ukugoba okucacileyo, amaqhuma, imibimbi, okanye ipeyinti ephaphazelayo.

12) Akukho zikrwelo okanye imikrwelo ebusweni bemveliso egqityiweyo

I-13) Ulwakhiwo olupheleleyo lwemveliso luqinile, lulungelelaniswa phantsi, kwaye akukho ukukhululeka kumacandelo xa kushukunyiswa. Amalungu aqinile kwaye akukho zithuba zicacileyo

14) Iilensi kunye neengcango zekhabhinethi zeglasi zicocekile ngaphandle kwamanqaku ancamathelayo, kwaye ukudibanisa okanye ukudibanisa kuqinile kwaye kuqinile.

15) Izixhobo ze-Hardware ezihlala zivulwa, njengeehenjisi, i-retractables, i-drawer slides, njl., Zifuna ukuvulwa nokuvala okuguquguqukayo.

I-16) Amacandelo okhuni oluqinileyo alukho iimpawu zokubola, imingxuma yezinambuzane, iifractures, njl., kunye nombala kunye nolwalathiso lweenkozo zokhuni zihambelana. Isiqulatho sokufuma siyahlangabezana neemfuno

17) Ukugquma kweendawo zokhuni akufuneki kube nemibimbi okanye ukuvuza kwepeyinti: ukugquma okanye ukugquma kwamalungu entsimbi akufuneki kube nokuxobuka, ukuhombisa, okanye ukuvuza kwepeyinti.

18) Ukugquma kwiindawo zokhuni kufuneka kube tyaba kwaye kugudileyo, ngaphandle kwemikrwelo, amabala amhlophe, amaqamza, amagwebu, kunye nokwahluka kombala ocacileyo.

19) Izixhobo zephaneli azinamngxuma, zikhululekile, zingenazinambuzane, ziqhekeziwe, ziqhekeziwe, zikrwele, zibethelelwe ngaphandle, zihlatywe, kunye nezinye izinto.

20) Umbala womphezulu kufuneka uhambelane, nokuba uthelekisa isiqwenga esinye kwizikhundla ezahlukeneyo okanye uthelekise inkqubo yonke, umbala kufuneka ungqinelane.

21) Akukho manqaku acacileyo esixhobo kumphezulu, njengamanqaku emela, amanqaku okutsala, ukuqhekeka, ukuqhekeka, isanti emnyama, kunye nokutshona.

22) Ihinge akufanele igobe okanye iphakame kakhulu, kwaye ayivumelekanga ukuba ilungise umnyango ngokugoba ihenjisi ukuze igcine ukucaba kwayo.

23) Iglasi kunye nezibuko kufuneka zifakwe ngaphandle kokugubha okanye ukukhulula

24) Imveliso ayinayo i-debris, i-protrusions ebukhali, i-burrs, amanqaku eglue, amnyama atshisiweyo, okanye ukutshiza ngokugqithiseleyo.

I-25) Ubungakanani obupheleleyo bemveliso egqityiweyo ihlangabezana neemfuno zomzobo, kwaye imilinganiselo yangaphandle ingaphakathi komgangatho ovumelekileyo wokunyamezela.

Izixhobo eziqhelekileyo ze-hardwareyokudilizwa kunye nokudibanisa ifanitshala

Izixhobo ze-Hardware zisetyenziselwa ngokubanzi ukulungisa nokudibanisa isakhiwo xa uchitha ifenitshala. Izihlanganisi eziqhelekileyo kwifanitshala ziquka iihenjisi, izihlanganisi (eccentric okanye isigxina), izilayidi zedrowa, izilayidi zocango olutyibilikayo, izibambo, izitshixo, izikhonkwane zokutshixa, iikomityi zokufunxa amacango, izixhaso zokwahlula, izinti zokuxhoma iimpahla, iipuli, imilenze, iibholiti, izikrufu zomthi, iinkuni zomthi. , iinzipho ezingqukuva, njl.

1. Ihinge

Iihenjisi zezona zakhiwo ziphambili ezidibanisa iindawo ezimbini ezihambayo, ikakhulu ezisetyenziselwa ukuvula nokuvala iingcango zekhabhinethi, zohlulwe zibe ziihenjisi eziveziweyo kunye neehenjisi ezifihliweyo.

1) Ming hinge

Iihenjisi zidla ngokuba ziihenjisi kuphela, kwaye xa zifakwe, inxalenye yepini yehinge ibonakaliswe kumphezulu wefenitshala. Iihenjisi zingasetyenziselwa iingcango ezakhelwe ngaphakathi kunye neengcango ezisongayo.

2) Ihenjisi efihliweyo

Ihinge efihliweyo ijikeleza ngentonga yokudibanisa kwaye ifihliwe ngaphakathi kwefenitshala ngexesha lofakelo ngaphandle kokuvuza.

2. Amacandelo oqhagamshelwano

I-Connector, eyaziwa ngokuba yi-fixed connector, inefuthe elithe ngqo kwisakhiwo kunye nokuqina kweemveliso zefenitshala. Isetyenziselwa ikakhulu ukudibanisa iipaneli zecala, iipaneli ezinqamlekileyo, kunye neepaneli zangasemva zefenitshala yekhabhinethi ukulungisa iipaneli zefenitshala. Intonga yokudibanisa ibandakanya izixhumi ze-eccentric kunye nezixhumi ezisisigxina.

1) Isidibanisi se-Eccentric

Ukusebenzisa umgama we-eccentric, qhagamshela i-plate ethe tyaba kwi-side plate, njengomgangatho kunye ne-side plate, kunye neplate ephantsi ingafakwa ukusuka phezulu okanye ecaleni.

2) Izixhumi ezisisigxina

Iqulethwe ngamacandelo amabini: i-screw kunye nomkhono kunye neplate yensimbi yasentwasahlobo. Emva kokucinezela uxhulumaniso ngesandla, into idityaniswe ngokusisigxina, ibonakaliswe ngoqhagamshelwano olunamandla kakhulu.

3. Isilayidi sedrowa

Iireyile zesilayidi zedrowa zenziwe ngepeyinti yokubhaka yentsimbi okanye izinto ezenziwe ngentsimbi. Ngokweendlela ezahlukeneyo eMpuma China, zinokwahlulwa zibe yipulley okanye uhlobo lwebhola. Ngokomgama ovela kwi-drawer ukuya kwikhabhinethi, ziyakwazi ukwahlula zibe yimizila yecandelo elinye, iileyili zecandelo eliphindwe kabini, kunye neentambo ezintathu zecandelo.

4. Ibholithi

Uhlobo lwe-fastener olubandakanya intloko kunye ne-bolt (umzimba we-cylindrical onemicu yangaphandle), ekufuneka ihambelane nekhethini kwaye isetyenziselwa ukuqinisa kunye nokudibanisa iindawo ezimbini kunye nemingxuma. Olu hlobo loqhagamshelwano lubizwa ngokuba ludibaniso lwebholiti.

5. I-tendon esetyhula

Enye yeendibano ezisetyenziswa ngokuqhelekileyo kunye nezixhobo zokudibanisa kwifenitshala yeepaneli, ezibunjwe njengentonga ejikelezayo kwaye ngokuqhelekileyo yenziwe ngamaplanga. Kwi-disassembly kunye ne-dissembly yefenitshala, ii-tendon zomthi zidlala indima yokumisa, kunye nobukhulu obusetyenziswa ngokuqhelekileyo be-6mm, 8mm, 10mm, kunye ne-12mm, kunye nobude be-20mm, 25mm, 30mm, 35mm, 40mm, kunye ne-50mm.

6. Ezinye izihlanganisi

Izikrufu, izikrufu zokuzicofa, amandongomane, iiwasha, iiwasha zasentwasahlobo, amantongomane e-cylindrical, amantongomane anembambo ezimbini, izibambo, njl.

Ixesha lokuposa: May-09-2024