Kukho iindidi ezininzi zefenitshala, njengefenitshala yomthi oqinileyo, ifenitshala yentsimbi ekhandiweyo, ifenitshala yeepleyiti, njl. Ngoko ke, xa umhloli efuna ukuhlola ifanitshala edityanisiweyo, kufuneka adibanise ifenitshala kwindawo, ngoko ke ngawaphi amanyathelo ezixhobo zokuqhawula nokudibanisa ifanitshala, indlela yokusebenza kwisiza, kwaye ngawaphi amanyathelo afanele athathwe. Apha ngezantsi kukho isishwankathelo solwazi oluluncedo olufanele ukukunceda.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

1. Ubungakanani bokuhlolwa kwendibano kwi-site 1) Umhloli kufuneka ahlanganise ubuncinane isethi enye yeemveliso ngokuzimeleyo ngokwemiyalelo yendibano. Ukuba ubungakanani bemveliso bukhulu kakhulu, abasebenzi befektri kufuneka bancede, qiniseka ukuba udibaniso kunye neengxenye ezihambelanayo zifakwe kwaye ziqhutywe ngumhloli ngokwakhe. 2) Indibano yezinye iimveliso inokugqitywa ngabasebenzi basefektri, kodwa kufuneka igqitywe phantsi kweliso lomhloli kuyo yonke inkqubo. Nika ingqalelo ukujonga yonke inkqubo yendibano yemveliso, ungagxili nje kwisiphumo sokugqibela sendibano. Indoda yempahla ayikwazi ukushiya indawo yendibano, kwaye ubuninzi bezixhobo ezifunekayo ngokuhlolwa (WI).

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

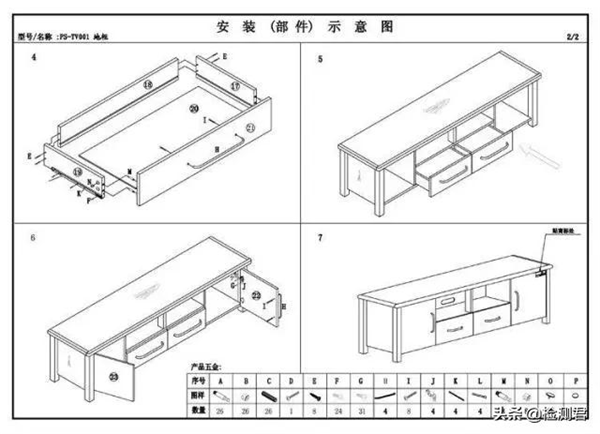

2.Amanyathelo okuhlanganisa kwi-site kunye nezilumkiso 1) Izixhobo ze-site kufuneka zifakwe ngokungqongqo ngokuhambelana nemiyalelo yendibano enikwe imveliso. Ngethuba lenkqubo yendibano, khangela ukuba amanyathelo kwimiyalelo yendibano ichanekile, ingaba icandelo ngalinye lihlangabezana neemfuno zobugcisa, nokuba ukulungelelaniswa kuqinile, nokuba izikhundla zomngxuma zichanekile. , ingaba imveliso iqinile, kwaye ingaba idinga ukusebenzisa izixhobo zangaphandle (ngokubanzi akuvumelekanga, kuxhomekeke kwiimfuno zencwadana) 2) Ngaphambi kokuhlanganisana, chonga inani lamaqhekeza emveliso, vula iphakheji yebhokisi, ubeke i-hardware. iphakheji kwindawo eyahlukileyo kwaye ubale ukunqanda ukulahleka okanye ukuxutywa nezincedisi ezivela kwezinye iimveliso. 3) Okokuqala khangela ukuba inani kunye nobukhulu bamacandelo ahambelana nenani eliphawulwe kwincwadana, kwaye uqaphele ukuba ungatshintshi indawo yamalungu angafanelekanga xa uhlanganisana. 4) Funda ngokucokisekileyo imiyalelo yendibano, okokuqala ukwahlula amacandelo aphambili ngokulandelelana kwendibano, kwaye u tyelele iipaneli ngokwahlukileyo ukuze ufakele. Kungcono ukuthatha imifanekiso yezi panel.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

5) Lungiselela izixhobo zokufakela ezifana ne-screwdrivers, i-wrenches, njl. Ngexesha lenkqubo yendibano, landela ngokungqongqo amanyathelo endibano kwimiyalelo yendibano yemveliso. Abahloli kufuneka bahlawule ingqwalasela ekhethekileyo: abasebenzi basefektri bahlala bethembele kumava ngexesha lokudibanisa, kwaye basilela ukufaka ngokuhambelana ngokupheleleyo namanyathelo kwimiyalelo. Le ndlela ayikwazi ukuvavanya ukuba imiyalelo yesixhobo ifanelekile kwaye iphelele. Ukuba imeko enjalo ifunyenwe, kufuneka imiswe / ilungiswe ngokukhawuleza. Ngexesha elifanayo, kukulungele ukufakela enye enye, kungekhona ezininzi ngexesha elifanayo, ukuze ungajongi endaweni. 6) Ngokuqhelekileyo, inkqubo yendibano yeemveliso ezininzi inokwahlulwa ibe ngamanqanaba amane: Isinyathelo sokuqala kukwenza i-skeleton yemveliso. Ngethuba le nkqubo, kufuneka kuhlawulwe ingqalelo ukuba imingxuma yokudibanisa i-skeleton ichanekile, kwaye ingaba ukufakwa kwezibophelelo ezifana ne-bolts zihamba kakuhle, ikhonkco kufuneka ivalwe, kwaye i-gap ye-skeleton kufuneka ifane. Inxalenye yesibini kukufaka iindawo ezisisigxina kunye nezidibeneyo zesakhiwo sokuqinisa kwi-skeleton. Ngethuba le nkqubo, nikela ingqalelo kwizixhobo ze-hardware, ngokukodwa i-screws, ukwenzela ukuba zonke iindawo kunye ne-fasteners zifakwe, kwaye ukhangele ukuba imingxuma yokudibanisa ifanelekile. Kufuneka kuqatshelwe ukuba i-phenomenon ye-screw hole dislocation ihlala ivela kwinkqubo yesibini. Inxalenye yesithathu kukufakela isixhobo sesikhokelo okanye iindawo ezihambayo ezidityaniswe ziihenjisi kwiindawo ezihambelanayo. Qaphela ukuba i-disassembly kunye ne-dissembly yamacandelo efenitshala inokuchithwa ngokupheleleyo kwaye ihlanganiswe ngamaxesha amaninzi ngaphandle komonakalo. Kule khonkco, kuyimfuneko ukunikela ingqalelo ukuba ngaba ezi nxalenye zidibene kanye. Kukho iingxaki zemingxuma ye-screw kunye neendawo ezonakalisiweyo. Inxalenye yesine, ukufakwa kwezinto ezincinci okanye ezihlobisayo okanye izixhobo. Ngexesha le nkqubo, nikela ingqalelo ukuba ubude be-screw buhlangabezana neemfuno, nokuba izixhobo zokuhombisa zinokuqiniswa ngokuqinileyo, nokuba indawo yomngxuma ifanelekile xa uvala isikrufu, kwaye imveliso ayinakukrweleka ngexesha lenkqubo, kunye nezixhobo. ayinakukhululwa.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

Iingxaki eziqhelekileyo 1. Kukho iindawo ezingekhoyo kwimveliso, ngakumbi izixhobo ze-hardware kwiphakheji encinci. Imingxuma efanelekileyo kwi-plate izaliswe ngepeyinti, kwaye i-hardware ayikwazi ukufakwa ngokufanelekileyo 4. Izixhobo ze-hardware azikwazi ukuvalelwa, kwaye umkhiqizo awuqini 5. Xa uvala izixhobo ze-hardware, iindawo ziphazamisekile, ziphazamisekile, zonakaliswe. , njl njl. Iindawo ezihambayo ezisebenzayo azikwazi ukutyhala kwaye zitsalwe kakuhle. 7. Iinxalenye zokudibanisa zonakaliswe, kwaye umphezulu wezixhobo ze-hardware zigqwalile. 8. I-gap phakathi kwamacandelo ngexesha lendibano inkulu kakhulu, okanye i-gap ayilingani

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

Iimfuno zomgangatho wemveliso kunye neendlela zokuhlola 1. Iindlela zokuhlola Umlinganiselo wesixhobo, ukuhlolwa okubonakalayo, ukubamba isandla, ukuhlola imveliso ngokweemfuno zobugcisa bendibano yemveliso kunye nobukhulu bomzobo kunye nokuma 2. Umgama wokuhlola kufuneka ube phantsi kokukhanya kwendalo okanye kufuphi nokukhanya kwendalo ( umzekelo: isibane se-fluorescent 40W), Umgama wombono 700-1000mm3. Iinkxalabo zokuhlola ukubonakala 1) I-Welding, i-rivets, i-tenon joints, njl. ezisetyenziselwa iindawo ezisisigxina akufanele zikhululeke. I-2) Izikrufu kunye neengxenye zokudityaniswa kwe-hardware akufanele zikhululeke. 3) Umphezulu wezixhobo ze-hardware awunama-scratches, i-plated (I-coating) umaleko uqinile, ngaphandle kokuwa okanye ukugqwala. I-4) Izixhobo ezithwala imithwalo kunye neendawo ezihambayo akufanele zibe nokuqhekeka, amaqhina, imingxuma yezibungu kunye nezinye iziphene. 5) Imibhobho yentsimbi efakelweyo kufuneka ingabinazintanda kunye nokhoko zikrazulwe kakuhle kwaye zingabi namanqaku ehamile. i-burrs, i-scratches 11) Ukugquma kweendawo zetsimbi kufuneka kungabikho phantsi kwezantsi, ama-bumps, i-sagging ecacileyo, i-bumps, imibimbi, ipeyinti ephaphazelayo 12) Umphezulu wemveliso egqityiweyo awunayo imikrwelo, imikrwelo (ibamba) ) Ukulimala 13) I-overall Ubume bemveliso buqinile, umhlaba ulungelelene, amacandelo awakhululekanga xa eshukunyiswa, i-seams iqinile, kwaye akukho sithuba esicacileyo. I-14) I-lens kunye nomnyango weglasi zicocekile kwaye azinamanqaku eglue, kwaye iglue okanye idibeneyo iqinile kwaye iqinile 15) Nayiphi na i-hardware ehlala ivuliwe Izixhobo, ezifana nee-hinges, i-shrinks, i-drawer slides, njl., zifuna utshintsho oluguquguqukayo. 16) Izixhobo zokhuni eziqinileyo azinakubola, imingxuma yeentshulube, iintanda, njl. njl., umbala kunye nolwalathiso lweenkozo zokhuni luyahambelana, kwaye umxholo wokufuma uhlangabezana neemfuno. 17) Ukugquma kweendawo zokhuni akufuneki kube nesikhumba esishwabeneyo kunye nokuvuza kwepeyinti: Ukugquma okanye ukugquma kwamalungu esinyithi kufuneka kungabikho ukuxobuka, ukuhombisa, kunye nokuvuza kwepeyinti. 18) Ukugquma kweendawo zokhuni kufuneka kube mpuluswa kwaye kugudileyo, ngaphandle kwemikrwelo, amabala amhlophe, amagwebu, amagwebu, kunye nokwahluka kombala ocacileyo. 19) Akukho mgodi, ukhululekile, udliwe ngamanundu, uqhekeziwe, uqhekeziwe, ubotshwe, ubethelelwe, uhlatywe, njl. 20) Umbala womphezulu ufana, nokuba yinto enye yezikhundla ezahlukeneyo okanye inkqubo yonke, umbala uyafuneka Ngokuhambelana 21) Akukho zimpawu zesixhobo ezicacileyo phezu komhlaba, iimpawu zemela, amanqaku okudonsa, iintanda, iintanda, isanti. mnyama, i-sag Lungisa ucango ukugcina ucango lugungxulwa 23) Iglasi kunye nezibuko kufuneka zingashukunyiswa, zikhululeke emva kofakelo Iimfuno zomzobo, ubukhulu bembonakalo bungaphakathi kobungakanani obuvumelekileyo. uluhlu lonyamezelo

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

Izixhobo eziqhelekileyo ze-hardware ze-disassembly kunye nendibano yefenitshala Izixhobo ze-Hardware zisetyenziselwa ngokubanzi ukulungisa nokudibanisa isakhiwo. Izihlanganisi eziqhelekileyo kwifanitshala ziquka iihenjisi, izihlanganisi (eccentric, esisigxina), izilayidi zedrowa, izilayidi zocango olutyibilikayo, Iziphatho, izitshixo, iiletshi, iingcango zokufunxa, izixhaso zokwahlula, izixhoma zempahla, iipuli, iinyawo, iibholithi, izikrufu zomthi, iidowels, izikhonkwane ezingqukuva, njl.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

1. I-hinge i-hinge isakhiwo esiphambili esidibanisa iindawo ezimbini ezihambayo, ezisetyenziselwa ukuvulwa kunye nokuvala umnyango wekhabhinethi. Yahlulwe ibe yihenjisi evulekileyo kunye nehenjisi emnyama Ivuza kumphezulu wefenitshala, kwaye ihenjisi ingasetyenziselwa iingcango ezakhelwe ngaphakathi kunye neengcango ezisongayo.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

2) I-hinge efihliweyo I-hinge efihliweyo ijikelezwa yintonga yokudibanisa, kwaye ifihliwe ngaphakathi kwefenitshala kwaye ayiphumi ngexesha lofakelo.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

2. I-Connectors I-Connectors zibizwa ngokuba yi-fixed connectors, enefuthe elithe ngqo kwisakhiwo kunye nokuqina kweemveliso zefenitshala. Ngokuqhelekileyo zisetyenziselwa ukudibanisa iipaneli zecala, iipaneli ezinqamlekileyo kunye neepaneli zangasemva zefenitshala yekhabhinethi, ukwenzela ukuba iipaneli zefenitshala zilungiswe. , intonga yokudibanisa ibandakanya i-eccentric yokudibanisa kunye neqhekeza elisisigxina. I-1) Isidibanisi se-eccentric sithatha umgama we-eccentric ukudibanisa i-plate ethe tye kunye ne-side plate, njengomgangatho kunye ne-side plate, kwaye i-plate ephantsi ingafakwa ukusuka phezulu okanye ukusuka kwicala.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

2) Umdibaniso osisigxina uqulethwe ngamacandelo amabini: i-screw kunye ne-sleeve ene-spring steel sheet. Emva kokuba uxhulumaniso lucinezelwe ngesandla, into idibaniswa ngokusisigxina, ebonakaliswe ngoqhagamshelwano oluqinileyo kakhulu.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

3. Izilayidi zedrowa Izilayidi zedrowa zenziwe ngevanishi yokubhaka yentsimbi okanye imathiriyeli eyenziwe ngentsimbi. Ngokweendlela ezahlukeneyo e-East China, zinokwahlulwa zibe luhlobo lwe-pulley okanye uhlobo lwebhola, njl. Ngokomgama wedrowa ekhupha ngaphandle kwekhabhinethi, inokwahlulwa ibe yicandelo elinye I-Track, i-double track, i-triple track.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

4. Uhlobo lwe-fastener olubandakanya intloko kunye ne-bolt (i-cylinder enentambo yangaphandle), ekufuneka ihambelane nekhethini ukuze idibanise kwaye idibanise iinxalenye ezimbini ngemingxuma. Olu hlobo loqhagamshelwano lubizwa ngokuba ludibaniso olubotiweyo.

5. Intonga ejikelezayo kunye nefenitshala yebhodi ye-tenon yenye yeendibano ezisetyenziswa ngokuqhelekileyo kunye nezixhobo zokudibanisa. Ukumila kwayo kufana nentonga engqukuva. Ngokuqhelekileyo yenziwe ngamaplanga. I-tenon yokhuni kwi-disassembly kunye nefenitshala yendibano idlala indima yokubeka. Iidiameter ezisetyenziswa ngokuqhelekileyo yi-6mm, 8mm, 10mm, 12mm, Ubude bungama-20mm, 25mm, 30mm, 35mm, 40mm, 50mm.

Amanyathelo ezixhobo kunye neemfuno eziphambili zokuhlolwa kwefenitshala

6. Ezinye izikhonkwane zokudibanisa, i-self-tapping screws, i-nut, i-washers, i-spring washers, i-cylindrical nuts, i-thread thread nuts, izibambo, njl.

Ixesha lokuposa: Jul-19-2022