1, Ukuhlolwa kweTire kunyeukuhlolwa komgangatho wembonakalo

Umgangatho wokubonakala kwetayara akufuneki ube naziphi na iziphene zembonakalo ezichaphazela kakhulu ubomi benkonzo yalo, njengokuqhekeka phakathi kwezinto ezahlukeneyo, isiponji esinje, ukuqhawuka komsesane wocingo, umsesane wocingo ukutsalela phezulu kakhulu, ukophuka kwentambo ezininzi, ukushwabana kwentambo yangaphakathi, kunye udini lwesithsaba esinentambo. Ukuba usebenzisa ibhanti ye-cushion, ukumila kwebhanti ye-cushion akufanele kuphelele okanye umzimba webhanti akufanele uqhekeke.

2, Ukuhlolwa kweTire, ukunyathela iimpawu zokunxiba kunye neempawu

Itayara langaphandle ngalinye kufuneka lixhotyiswe ngeempawu ezi-4 zokunxiba ezibonakalayo malunga nemigama elinganayo kumjikelo, kwaye ubude bawo bungabi ngaphantsi kwe-1.6 mm.

Ivili ngalinye kufuneka libe neempawu emagxeni kumacala omabini abonisa indawo yophawu lokunyathela.

3, Umlinganiselo wedatha yokuhlola itayara

1). Umlinganiselo weparameters eziphambili zamatayara

Inkcazo, isalathisi somthwalo (okanye inqanaba), umthamo ohambelanayo womthwalo kunye noxinzelelo lokunyuka kwamaxabiso, iirim ezilinganisiweyo, ubungakanani obutsha bethayara, ubukhulu bokusetyenziswa, i-radius yomthwalo we-static, i-radius ejikelezayo, kunye nokusetyenziswa okuvumelekileyo kwamatayara emoto kufuneka kuhambelane ne-GB / T2978 okanye ishishini elifanelekileyo. amaxwebhu obugcisa.

2). ITire ihlola ubungakanani obutsha bomphetho wesondo

Ububanzi bubonke kunye nobubanzi obungaphandle becandelo letayara liya kuhambelana nezibonelelo zeSihlomelo A,

3). Imbalelwano phakathi kwesimboli yesantya setayara kunye nesantya esiphezulu sokuqhuba

Imbalelwano phakathi kweesimboli zesantya samatayara kunye nesantya esiphezulu kufuneka ihambelane namagatya eSihlomelo B

4). Imbalelwano phakathi kwesalathiso somthwalo wamatayara kunye nomthamo womthwalo

Imbalelwano phakathi kwesalathiso somthwalo wamatayara kunye nomthamo womthwalo kufuneka ihambelane namalungiselelo eSihlomelo C.

4, Ukuhlolwa kweTireukuhlolwa kokusebenza kokhuseleko

Ngokweemfuno, qhuba uvavanyo lokusebenza kwamandla, uvavanyo lokumelana nebead, uvavanyo lokuqina, uvavanyo lokusebenza olunoxinzelelo oluphantsi, kunye novavanyo olukhawulezayo lokusebenza kumatayara asampulu.

1). Ukusebenza kokuqina kweTire

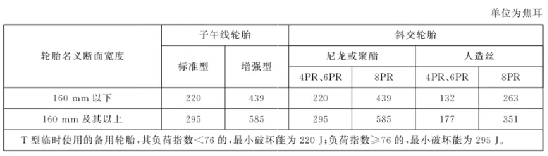

Ifanele amatayara e-diagonal, i-T-shaped temporary spare tires, kunye namathaya e-radial ane-nominal aspect ratio ye-50 nangaphezulu. Uvavanyo lwentsebenzo yamandla etayara kufuneka lube namandla okusilela angekho ngaphantsi kwexabiso elichaziweyo kwitheyibhile engezantsi kwindawo nganye yovavanyo.

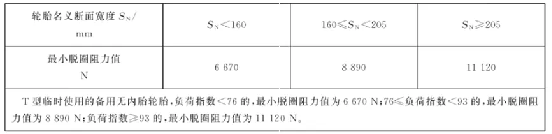

2). I-Tubeless tayara intsimbi yokungagungqi

Ifanelekile i-diagonal tubeless tayara, i-T-shaped temporary spare tyhubhu amathayi, kunye namathayi e-radial tubeless ane-nominal aspect ratio ye-50 nangaphezulu. Uvavanyo lokumelana nentsimbi yetayara kufuneka libe noxhathiso olungagungqiyo kwindawo nganye yovavanyo engekho ngaphantsi kwezibonelelo ezikule theyibhile ingezantsi.

3). Ukusebenza kokuqina kweTire

Emva kovavanyo lwentsebenzo ehlala ixesha elide, uxinzelelo lwetayara akufanele lube ngaphantsi kwe-95% yoxinzelelo lovavanyo lokuqala oluchaziweyo; Emva kokuba uvavanyo lugqityiwe, akufuneki kubekho i-delamination, i-ply cracking, intambo yokuqhawula intambo, ukuqhawuka kwentambo, ukuqhekeka (ngaphandle kwamatayara ekhephu e-PTBC), ukuqhekeka ngokudibeneyo, ukuqhekeka, okanye ukuguqulwa okungaqhelekanga komzimba wetayara ekuhlolweni kwenkangeleko. Ukuba itayara lonakalisiwe, umaleko ongangeni moya kufuneka uphinde ujongwe.

4). Ukusebenza koxinzelelo oluphantsi lwetayara

Ilungele amatayara e-radial, kodwa ayibandakanyi i-T-uhlobo lwamavili exeshana. Emva kovavanyo lwentsebenzo yoxinzelelo oluphantsi lwetayara, uxinzelelo lwetayara akufanele lube ngaphantsi koxinzelelo oluchaziweyo lokuqala lovavanyo, i-95%. Emva kokuba uvavanyo lugqityiwe, akufuneki kubekho i-delamination (ukunyathela, i-sidewall, i-ply, i-airtight layer, ibhanti okanye i-buffer layer, isondo), i-ply cracking, i-ply peeling, i-ply breakage, i-chipboard (ngaphandle kwamavili ekhephu e-PTBC), ukudibanisa ngokubambisana, ukuqhekeka, kunye nokuguqulwa okungaqhelekanga komzimba wesondo ekuhlolweni okubonakalayo.

5). Ukusebenza kwesantya esiphezulu samatayara

Emva kovavanyo lwentsebenzo yesantya esiphezulu, uxinzelelo lwetayara akufanele lube ngaphantsi kwe-95% yoxinzelelo oluchaziweyo lokuqala lovavanyo; Emva kokuba uvavanyo lugqityiwe, akufuneki kubekho i-delamination ecacileyo (ukunyathela, i-sidewall, umaleko weply, umaleko ongangeni moya, umaleko webhanti okanye umaleko we-buffer, i-bead yethayara), iintanda ze-ply, ukukrazula kweply, ukuqhekeka kweply entsha, ukuqhekeka kweentyatyambo, ukuqhekeka ngokudibeneyo, ukuqhekeka, okanye ukuguqulwa okungaqhelekanga kwetayara ngexesha lokuhlola okubonakalayo. Amatayara anesantya esiphezulu esingama-300km/h okanye ngaphezulu avumelekile ukuba abe namadyungudyungu kumphezulu okanye ukuqhekeka okubangelwa kukugqabhuka,

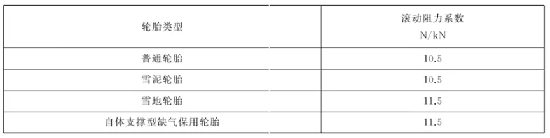

6). Ukuhlolwa kokusebenza kokumelana neTire

Isebenza kumatayara eradial, kodwa ayibandakanyi amatayara anekhowudi yerim ye-rim ye-nominal ye-<10 kunye nekhowudi yerim ye-rim ye-25, kunye namatayara angama-spare osetyenziso lwexeshana kuphela, amatayara akhethekileyo, amatayara okugijima, kunye namatayara agxininisiweyo. I-coefficient yokumelana ne-rolling yetayara akufanele idlule ubuninzi bexabiso lomda ochazwe kwitheyibhile engezantsi.

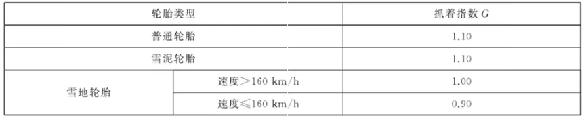

7). Ukusebenza okunxulumeneyo okubambelela kwamatayara kwimigangatho yendlela emanzi

Isebenza kumatayara eradial, kodwa ayibandakanyi amatayara anekhowudi yerim ye-rim ye-nominal ye-<10 kunye nekhowudi yerim ye-rim ye-25, kunye namatayara angama-spare osetyenziso lwexeshana kuphela, amatayara akhethekileyo, amatayara okugijima, kunye namatayara agxininisiweyo. Isalathiso sokubamba esizalanayo somphezulu wendlela emanzi yetayara akufuneki sibe ngaphantsi kwexabiso eliqingqiweyo eliqingqiweyo elichazwe kwiTheyibhile yesi-4.

Le ingentla yimigangatho kunye neendlela zokuhlola ivili lemoto, kubandakanywa nokuhlolwa komgangatho wokubonakala kwamatayara, umlinganiselo weparameter engundoqo, ukuhlolwa kokusebenza kokhuseleko, njl.

Ixesha lokuposa: Jul-10-2024