Amanqaku aphambili kwiuvavanyo kwisizakwayeukuhlolwayefenitshala yangaphakathi

1. Ubungakanani, ubunzima, kunye nokuhlolwa kombala (ngokweemfuno zekhontrakthi kunye ne-block spec, kunye neesampuli zokuthelekisa).

2. Uxinzelelo lwe-static kunye novavanyo lwempembelelo (ngokweemfuno kwingxelo yovavanyo).

3. Uvavanyo lokuguda, qinisekisa ukuba zone iinyawo zikwinqwelomoya enye emva kofakelo.

4. Uvavanyo lweNdibano: Emva kwendibano, khangela ukulungelelaniswa kwenxalenye nganye kwaye uqinisekise ukuba izikhewu azikho zikhulu kakhulu okanye ziphosakele; Kukho iingxaki zokungakwazi ukuhlanganisa okanye kunzima ukudibanisa.

5. Uvavanyo lokuwisa.

6. Vavanya ubumanzi benxalenye yomthi.

7. Uvavanyo lwe-slope(imveliso ayinakubhukuqa kwithambeka le-10 °)

8. Ukuba kukho iipateni zemizila ebusweni, imivimbo kunye neepatheni ebusweni kufuneka zibe yinto efanayo, igxininise, kwaye i-symmetrical. Imivimbo efanayo kwiindawo ezahlukeneyo kufuneka ihambelane, kwaye ukubonakala ngokubanzi kufuneka kuququzelelwe.

9. Ukuba kukho iindawo zokhuni ezinemingxuma, imida yemingxuma kufuneka iphathwe kwaye kungabikho burrs ngokugqithiseleyo, ngaphandle koko inokulimaza umqhubi ngexesha lofakelo.

10. Khangela umphezulu wenxalenye yokhuni, ngokukodwa qaphela umgangatho wepeyinti.

11. Ukuba kukho izikhonkwane zobhedu kunye nezinye izesekeli kwimveliso, ubuninzi kufuneka buhlolwe kwayexa kuthelekiswa neisampuli yotyikityo. Ukongeza, indawo kufuneka ilingane, izithuba kufuneka zihambelane ngokusisiseko, kwaye ukufakela kufuneka kuqine kwaye akunakutsalwa ngokulula.

12. I-elasticity yemveliso akufanele ihluke kakhulu kwisampuli. Ukuba kukho intwasahlobo, ubukhulu kufuneka buthelekiswe kunye nesampuli.

13. Kukho uluhlu lwezesekeli kwi-asembly manual, ekufuneka ithelekiswe kunye neyona nto. Ubuninzi kunye neenkcukacha kufuneka zihambelane, ngakumbi ukuba kukho iinombolo kuyo, kufuneka zihambelane ngokucacileyo.

14. Ukuba kukho imizobo yendibano kunye namanyathelo kwincwadana, khangela ukuba umxholo uchanekile.

15. Khangela imiphetho kunye neekona zemveliso ukuqinisekisa ukuba akukho mibimbi ecacileyo okanye iziphene ezingalinganiyo, kwaye ngokubanzi, akufanele kubekho ukungafani okuphawulekayo kwisampuli esayiniweyo.

16. Ukuba kukho iinxalenye zetsimbi kwimveliso, khangela iindawo ezibukhali kunye nemiphetho.

17. Jonga iimeko yokupakisha. Ukuba i-accessory nganye inepakethe eyahlukileyo, kufuneka ilungiswe ngokufanelekileyo ngaphakathi kwebhokisi.

18. Iiindawo zokuweldakufuneka ihlolwe ngononophelo, kwaye iindawo ze-welding kufuneka ziphuculwe ngaphandle kwe-slag ye-welding ebukhali okanye engaphezulu. Umphezulu kufuneka ube mcaba kwaye ube mhle.

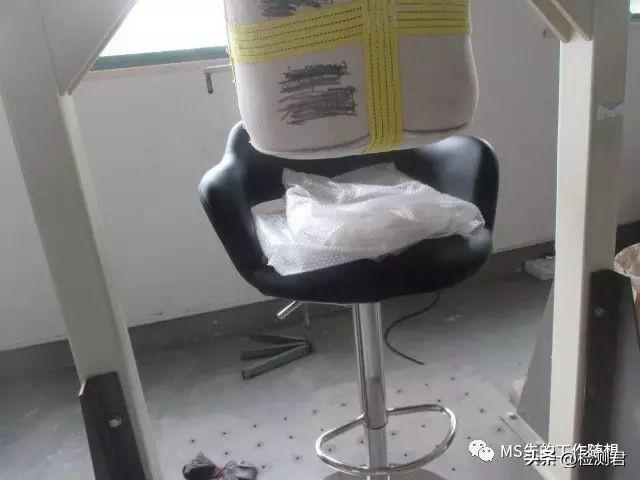

Iifoto zovavanyo lwesiza

Uvavanyo lwe-Wobbly

Uvavanyo lwe-Tilt

Uvavanyo lokuLayisha oluzinzileyo

Uvavanyo lweMpembelelo

Uvavanyo lweMpembelelo

Ukujonga umxholo wokufuma

Iifoto zeziphene eziqhelekileyo

Ukushwabana kumphezulu

Ukushwabana kumphezulu

Ukushwabana kumphezulu

PU yonakele

Uphawu lomkrwelo kumlenze womthi

Ukuthunga kakubi

PU yonakele

Isikrufu asilungiseki kakuhle

I-zipper skew

Uphawu lokubohla epalini

Umlenze womthi wonakalisiwe

Isitayile asilungiseki kakuhle

I-welding engalunganga, ezinye iindawo ezibukhali kwindawo ye-welding

I-welding engalunganga, ezinye iindawo ezibukhali kwindawo ye-welding

Eletroplated kakubi

Eletroplated kakubi

Eletroplated kakubi

Eletroplated kakubi

Ixesha lokuposa: Aug-14-2023