Impahla yeDenim ibisoloko iphambili kwifashoni ngenxa yomfanekiso wayo wobutsha kunye namandla, kunye neempawu zodidi lomntu ngamnye kunye nebenchmarking, kwaye ngokuthe ngcembe iye yaba yindlela yokuphila edumileyo kwihlabathi liphela.

Uphando lwedatha lubonisa ukuba ukuya kuthi ga kwi-50% yabantu baseYurophu banxibe i-jeans esidlangalaleni, kwaye inani laseNetherlands lifikelele kwi-58%. Inkcubeko ye-denim e-United States igxininise kakhulu, kwaye inani leemveliso ze-denim liphantse lafikelela kwi-5-10 iziqwenga, okanye nangaphezulu. E-China, iimpahla ze-denim nazo zithandwa kakhulu, kwaye kukho intaphane yeempawu ze-denim kwiindawo zokuthenga kunye nezitrato. Ingingqi yaseTshayina iPearl River Delta yindawo eyaziwayo yehlabathi "yeshishini ledenim".

Ilaphu ledenim

Idenim, okanye iDenim, iguqulelwa ngendlela ecacileyo njengolusu. Ikotoni isiseko se-denim, kwaye kukho i-cotton-polyester edibeneyo, i-cotton-linen, i-cotton-wool, njl., kunye ne-elastic spandex yongezwa ukuze ikhululeke kwaye isondele.

Amalaphu edenim abonakala eluhlobo olulukiweyo. Kwiminyaka yakutshanje, ilaphu elinithiweyo ledenim liye lasetyenziswa ngakumbi nangakumbi. Ine-elasticity eyomeleleyo kunye nentuthuzelo kwaye isetyenziswa ngokubanzi kuyilo lwempahla yedenim yabantwana.

I-denim lilaphu elikhethekileyo elizalwe ngendlela yemveli. Emva kokuhlanjwa kwemizi-mveliso kunye nokugqiba itekhnoloji, ilaphu lomqhaphu elinomqhaphu linembonakalo yendalo yokuguga, kwaye iindlela ezahlukeneyo zokuhlamba zisetyenziselwa ukufikelela kwiziphumo zoyilo lomntu.

Imveliso kunye neentlobo zeempahla ze-denim

Ukuveliswa kwempahla ye-denim yamkela inkqubo ehamba phambili ehamba phambili, kunye nezixhobo ezahlukeneyo zokuvelisa kunye nabasebenzi abasebenzayo bahlanganiswe ngokugqithiseleyo kumgca omnye wokuvelisa. Iyonke inkqubo yokwenziwa kwemveliso ibandakanya uyilo lwezitayile, iinkcukacha kunye neenkqubo zemveliso, kunye nokuhlolwa kwezinto eziphathekayo, ukucwangciswa, kunye nolusu. , ukusika, ukuthunga, ukuhlamba, uku-ayina, ukomisa kunye nokubumba kunye nezinye iinkqubo zokuvelisa.

Iintlobo zempahla yedenim:

Ngokwesitayile, inokwahlulwa ibe ziibhulukhwe zedenim, iziketi zedenim, iijakethi zedenim, iihempe zedenim, iivesti zedenim, idenim culottes kunye neelokhwe zamadoda, abafazi nabantwana.

Ngokokuhlanjwa kwamanzi, kukho ukuhlamba okuqhelekileyo, ukuhlamba okuziinkozo eziluhlaza, ukuhlanjwa kwekhephu (ukuhlamba i-snowflake kabini), ukuhlamba amatye (kwahlulwe kube lula kunye nokugaya okunzima), ukuhlanjululwa kwamatye, ukuhlanjululwa (kwahlulwe kwi-bleaching ekhanyayo kunye nenzima), i-enzyme, i-enzyme yamatye. , i-enzyme yamatye ihlanjululwe, kunye nokugqithisa. Hlamba njl.

Amanqaku aphambili okuhlola iimpahla zedenim

Ukujonga isimbo

Ubume behempe bunemigca eqaqambileyo, ikhola ilula, i-lap kunye nekhola ijikelezileyo kwaye igudileyo, kwaye umda ongezantsi wezwane uqondile; ibhulukhwe inemigca egudileyo, imilenze yebhulukhwe ithe tye, kwaye amaza angaphambili nasemva agudileyo kwaye athe tye.

Imbonakalo yelaphu

Ukugxila: Imbonakalo yelaphu

Ingqalelo kwiinkcukacha

Ukuzulazula, umsonto obalekayo, umonakalo, umbala omnyama nothe tyaba othe tyaba, amanqaku okuhlamba, ukuhlanjwa okungalinganiyo, amabala amhlophe natyheli, kunye namabala.

Uvavanyo lwe-Symmetry

Ukugxila: I-Symmetry

Ukujonga ukuhambelana

Amanqaku aphambili okuhlolwa kwe-symmetry yee-denim phezulu:

Ubungakanani bekhola ekhohlo nasekunene, ikhola, iimbambo, kunye nemikhono kufuneka ihambelane;

Ubude bemikhono yomibini, ubukhulu bemikhono yomibini, ubude befolokhwe, ububanzi bomkhono;

Isigqubuthelo sebhegi, ubungakanani bokuvula ingxowa, ukuphakama, umgama, ukuphakama kwethambo, izikhundla zokuphulwa kwethambo lasekhohlo nasekunene;

Ubude bempukane kunye neqondo lokujinga;

Ububanzi beengalo zombini nezangqa zombini;

Amanqaku aphambili okuhlolwa kwe-symmetry yeejini:

ubude nobubanzi bemilenze yebhulukhwe yomibini, ubukhulu beenzwane, imibhinqo emithathu, izibini ezine zamathambo asemacaleni;

Ngaphambili, ngasemva, ngasekhohlo, ngasekunene kunye nokuphakama kwebhegi yespleen;

Indawo yendlebe kunye nobude;

Ukuhlolwa komsebenzi

Ujoliso: ubugcisa

Ukuhlolwa kwe-multi-dimensional kunye nokuqinisekisa

Umsonto ongezantsi welungu ngalinye ufanele uqine, yaye akufuneki kubekho zijumpisi, imisonto eqhawukileyo, okanye imisonto edadayo. Imisonto ye-splice akufanele ibe kwiindawo ezibonakalayo, kwaye ubude bokuthunga akufanele bube buncinci okanye bube buninzi kakhulu.

Amanqaku aphambili okuhlolwa komsebenzi weebhatyi zedenim:

Izijekulo zokuthunga kufuneka zibe nokuphepha imibimbi kwimicu yokuxhoma. Nika ingqalelo kula malungu alandelayo: ikhola, ipleyiti, iifolokhwe zemikhono, imisesane yokunamathisela, kunye nokuvuleka kwepokotho;

Ubude beplakethi kufuneka buhambelane;

Umphezulu wekhola kunye nomphezulu wengxowa kufuneka ube mpuluswa kwaye ungajiki;

Ingaba i-thread-thread stitching yecandelo ngalinye ihlangabezana neemfuno kunye nokuba i-sling iqinile.

Amanqaku aphambili okuhlolwa kwejean:

Izijekulo zokunxiba ibhulukhwe kufuneka zikhuseleke izikhewu;

I-zipper akufanele ishwabene, kwaye amaqhosha kufuneka abe flat;

Iindlebe azifanele zigoso, indawo yokumisa kufuneka isikwe icoceke, kwaye iindlebe neenyawo kufuneka zifakwe ebhulukhweni;

Indawo yomnqamlezo wamaza kufuneka ilungelelaniswe, kwaye umsebenzi kufuneka ucoceke kwaye ungabinaboya;

Umlomo webhegi kufuneka ube tye kwaye ungavezwa. Umlomo wengxowa kufuneka uthe tye;

Ukubekwa kweliso le-phoenix kufuneka kuchaneke kwaye umsebenzi kufuneka ucoceke kwaye ungabi naboya;

Ubude kunye nobude be-jujube kufuneka bufezekise iimfuno.

uvavanyo lomsila

Ukugxila: Uku-ayina kunye nefuthe lokuvasa

Qwalasela ngononophelo umkhondo

Zonke iindawo kufuneka zi-ayinwe kakuhle, ngaphandle kokuba tyheli, amabala amanzi, amabala okanye umbala;

Imisonto kuzo zonke iindawo kufuneka isuswe ngokucokisekileyo;

Ukuhlamba okugqwesileyo, imibala eqaqambileyo, ukuva kwesandla esithambileyo, akukho mabala atyheli okanye ii-watermark.

Ugxininiso: Izinto eziphathekayo

Ukuqina, indawo, njl.

Amanqaku, indawo yeleyibhile yesikhumba kunye nesiphumo sokuthunga, nokuba iileyibhile zichanekile kwaye nokuba kukho naziphi na izinto ezishiyiweyo, ukumila kwengxowa yeplastiki, inaliti, kunye nebhokisi;

Iqhosha le-racquet elibetha izikhonkwane kufuneka liqine kwaye alikwazi ukuwa;

Landela ibhilidi yemiyalelo yezixhobo ngokusondeleyo kwaye ubeke ingqalelo kwimpembelelo yomhlwa.

Indlela yokupakisha, ibhokisi yangaphandle, njl.

Izambatho ziboshwe ngokufanelekileyo kwaye zihamba kakuhle, zilandela ngokungqongqo imiyalelo yokupakisha.

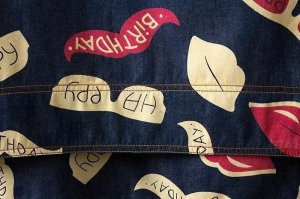

Ujoliso: i-embroidery

Umbala, indawo, umsebenzi, njl.

Ingaba umbala, izinto eziphathekayo kunye neenkcukacha zeenaliti zokuthungatha, i-sequins, ubuhlalu kunye nezinye izixhobo zichanekile, nokuba kukho i-discolored, i-variegated kunye ne-deformed sequins kunye namaso;

Ingaba indawo yokuhombisa ichanekile, nokuba isekhohlo nekunene ziyalingana, kwaye nokuba ukuxinana kulinganayo;

Ingaba ubuhlalu kunye nobucwebe beentambo zesikhonkwane ziqinile, kwaye intambo yokudibanisa ayinakuba yinde kakhulu (akukho ngaphezu kwe-1.5cm / inaliti);

Amalaphu ahonjisiweyo kufuneka angabi nemibimbi okanye amadyungudyungu;

Iziqwenga zokusika i-embroidery kufuneka zicoceke kwaye zicoceke, zingabi namanqaku empuphu, ukubhala ngesandla, amabala e-oyile, njl., kunye neziphelo zentambo kufuneka zicoceke.

Ugxininiso: Ukushicilela

Ukuqina, indawo, njl.

Ingaba indawo ichanekile, ingaba indawo yeentyatyambo ichanekile, ingaba kukho naziphi na iimpazamo okanye ukungabikho, nokuba umbala usemgangathweni;

Imigca kufuneka igudiswe, icoceke kwaye icace, ukulungelelaniswa kufuneka kuchaneke, kwaye i-slurry kufuneka ibe yi-moderate thickness;

Akufuneki kubekho kuphetshethwa kombala, ukucolwa kwentsimbi, ukudyobheka, okanye ukujika umva;

Akufunekanga ivakale iqinile okanye incangathi.

Ukugxila: uvavanyo olusebenzayo

Ubungakanani, ibhakhowudi, njl.

Ukongeza kula manqaku angasentla, uvavanyo olusebenzayo lomxholo olandelayo luyafuneka:

Ukuhlolwa komgangatho;

Uvavanyo lokuskena ibhakhowudi;

Ukulawulwa komgqomo kunye nokuhlolwa kobunzima;

Uvavanyo lwebhokisi yokulahla;

Uvavanyo lokukhawuleza kombala;

Uvavanyo lokuqina;

Umlinganiselo wokupakisha;

uvavanyo lwelogo

Uvavanyo lokubona inaliti;

Ezinye iimvavanyo.

Ixesha lokuposa: Jan-19-2024