1. Umda

Iimfuno zobugcisa kunye nezinto zokuvavanya iimeko zokusetyenziswa, ukusebenza kombane, iipropati zomatshini kunye nokusebenza kwendalo yeebhetri eziphambili ze-lithium (iibhetri zewashi, ukufundwa kweemitha zombane), njl.

Ukwamkelwa, ukuqinisekiswa rhoqo, kunye nokuhlolwa okupheleleyo kokusebenza kweebhetri eziphambili ze-lithium

Ubushushu obuphezulu kunye obuphantsi butshintshana ukufuma kunye negumbi lokuvavanya ubushushu

Igumbi lovavanyo lokutshiza ngetyuwa

I-Vernier caliper

Umvavanyi wokusebenza kwebhetri

Isixhobo sovavanyo lokungcangcazela

Isixhobo sovavanyo lwempembelelo

multimeter

3.1 Iimfuno zokupakishwa

Uyilo lokupakisha kufuneka luhambelane nendalo, iimpawu kunye nokugcinwa kunye neemeko zokuthutha imveliso. Ibhokisi yokupakisha kufuneka iphawulwe ngegama lomenzi, igama lemveliso, imodeli yemveliso, umhla wokwenziwa kunye nobungakanani bokupakishwa. Umphandle webhokisi yokupakisha kufuneka uprintwe okanye uncanyathiselwe iimpawu zothutho ezifana ne "Handle ngenkathalo", "Ukoyika ukumanzi", "Phezulu" njalo njalo. Iilogo eziprintiweyo okanye ezincanyathiselwe ngaphandle kwebhokisi yokupakisha kufuneka zingafihli okanye ziwe ngenxa yeemeko zothutho kunye neemeko zendalo. Ibhokisi yokupakisha kufuneka ihlangabezane neemfuno zobungqina bokufuma, ubungqina bothuli kunye nobungqina bokuthuthumela. Ingaphakathi lepakethe kufuneka libe noluhlu lokupakisha, isatifikethi semveliso, izincedisi kunye namanye amaxwebhu afanelekileyo.

3.2 Iimfuno ezisisiseko

3.2.1 Uluhlu lobushushu

Ubushushu be-ambient kufuneka buhambelane netheyibhile engezantsi.

| Hayi. | Uhlobo Lwebhetri | ubushushu (℃) |

| 1 | ibhetri iwotshi (Li-SOCl2) | -55 -85 |

| 2 | Ukucima kombane imitha yokufunda ibhetri(Li-MnO2) | -20 - 60 |

3.2.2 Uluhlu lokufuma

Ukufuma komoya okuhambelanayo kufuneka kuhambelane netheyibhile engezantsi.

| Hayi. | Imeko | Ubuntu bezizalwane |

| 1 | Umndilili ngonyaka | 75 |

| 2 | Iintsuku ezingama-30 (ezi ntsuku zisasazwa ngokwemvelo unyaka wonke) | 95 |

| 3 | Zivele ngebhaqo ngezinye iintsuku | 85 |

3.2.3 Uxinzelelo lwe-atmospheric

63.0kPa~106.0kPa (ubude obuyi-4000m nangaphantsi), ngaphandle kweemfuno zee-odolo ezizodwa. Iindawo eziphakamileyo eziphakamileyo zifuna ukusebenza okuqhelekileyo kwindawo yokuphakama kwe-4000m ukuya kwi-4700m.

3.3Ilogo kunye nemilinganiselo

Iibhetri zokuqala zeLithium kufuneka ubuncinane ziphawulwe ngegama lomenzi, igama zorhwebo okanye uphawu lokuthengisa, umhla wokuvelisa, imodeli, amandla ombane aqhelekileyo, umthamo wegama, kunye nophawu lwesiqinisekiso sokhuseleko. Iibhetri kufuneka ziphawulwe ngo "Isilumkiso" kwaye zibe noku kulandelayo okanye intetho efanayo: "Ibhetri inomngcipheko womlilo, ukuqhuma kunye nokutsha. Musa ukutshajisa, ukuqhaqha, ukucudisa, ukushisa ngaphezu kwe-100 ° C okanye ukutshisa. Yigcine kwipakethe yokuqala. phambi kokusetyenziswa "Umxholo ophawulweyo kufuneka ungqinelane neenkcukacha zobugcisa.

Ubuncinci obucacileyo bebhetri ye-lithium yokuqala ibandakanya ubuncinci i-voltage ye-nominal, i-voltage yesiphaluka evulekileyo, ubushushu bokusebenza, umthamo wegama, amandla aqhelekileyo, ukusebenza kwe-pulse, ubuninzi obuqhubekayo bokukhutshwa ngoku, umyinge wonyaka wokuzikhupha, ubungakanani, ifom yokudibanisa, uphawu lokuthengisa, kunye ukwenziwa kwelogo yeNkampani kunye nezinye iziqulatho.

(1) Vula amandla ombane wesiphaluka

(2) Umbane wokulayisha

(3) Ukusebenza kwe-Pulse

(4) Ukusebenza kwePasivation

(5) Umthamo wegama (usebenza kuvavanyo olupheleleyo lokusebenza)

3.5Iimfuno zokusebenza koomatshini

Ibhetri kufuneka ivavanye amandla etheminali, uvavanyo lwefuthe, kunye novavanyo lokungcangcazela oluchazwe kwi-5.6 yalo mgangatho wovavanyo. Emva kovavanyo, ibhetri ayiyi kuvuza, ikhuphe, i-short-circuit, igqabhuke, iqhume, okanye ibambe umlilo, kwaye i-welding piece ayiyi kuba nokuphuka okanye umonakalo obonakalayo. Umgangatho Izinga lokutshintsha lingaphantsi kwe-0.1%.

3.6 Ukusebenza kwe-soldering

3.6.1 I-Solderability (isebenza kwiintlobo ezineentsimbi ze-solder tabs)

Xa ibhetri ivavanywa kwi-5.7.1 yalo mgangatho wovavanyo, amandla okumanzisa akufunekanga abe ngaphantsi kwe-90% yethiyori yamandla okumanzisa.

3.6.2 Ukumelana nobushushu be-welding (esebenzayo kwiintlobo ezineentsimbi ze-welding tabs)

Ibhetri iphantsi kovavanyo lwe-5.7.2 yalo mgangatho wovavanyo. Emva kovavanyo, ukubonakala kwebhetri ephambili ye-lithium ayinayo nayiphi na umonakalo womatshini. Uvavanyo lombane kufuneka luhambelane neemfuno ezifanelekileyo zeenkcazo zobugcisa.

3.7 Iimfuno zokusebenza kokusingqongileyo (zisebenza kuvavanyo olupheleleyo lokusebenza)

Iibhetri eziziiprayimari zeLithium zivavanywa ngokusingqongileyo kwi-5.8 yalo mgangatho wovavanyo. Uvavanyo lombane olwenziwa emva kovavanyo luya kuhambelana neemfuno zobuchwepheshe ezicacileyo zeenkcukacha zobugcisa.

3.8 Uvavanyo lokhuseleko (lusebenza kuvavanyo olupheleleyo lokusebenza)

Iibhetri eziziiprayimari zeLithium kufuneka zihlangabezane nezi mfuno zilandelayo zobugcisa xa uqhuba iimvavanyo zokhuseleko kwi-5.9 yalo mgangatho wovavanyo.

| Hayi. | Iiprojekthi zokulinga | Imfuneko |

| 1 | Ukulinganisa ukuphakama okuphezulu | Akukho kuvuza, akukho kukhutshwa, akukho sekethi emfutshane, akukho kugqabhuka, akukho luqhushumbo, akukho mlilo,Inqanaba lokutshintsha ubunzima kufuneka libe ngaphantsi kwe-0.1%. |

| 2 | isimahla yonke | |

| 3 | isiphaluka esifutshane sangaphandle | Ayitshisi, igqabhuke, ayigqabhuki, okanye ibambe umlilo. |

| 4 | Impembelelo yento enzima | Akukho qhushumbo, akukho mlilo. |

| 5 | i-extrusion | |

| 6 | Ukutshaja okungaqhelekanga | |

| 7 | Ukukhupha ngenkani | |

| 8 | ukuxhatshazwa okushushu |

4. Iindlela zokuvavanya

4.1 Iimfuno ngokubanzi

4.1.1Iimeko zovavanyo

Ngaphandle kokuba kuchazwe ngenye indlela, lonke uvavanyo kunye nemilinganiselo iya kwenziwa phantsi kwezi meko zokusingqongileyo zilandelayo:

Ubushushu: 15℃~35℃;

Ukufuma okuhambelanayo: 25% ~ 75%;

Uxinzelelo lomoya: 86kPa~106kPa.

4.2 Tshekisha amaxwebhu obugcisa afanelekileyo

(1) Qinisekisa ukuba ubungakanani obuchaziweyo kunye negama liyahambelana nefomu yokuhlola ukuhanjiswa;

(2) Khangela ukuba ngaba umenzi-mveliso ungumthengisi ofanelekileyo.

4.3 Ukuhlolwa kokupakishwa

(1) Khangela ukuba ibhokisi yokupakisha iphawulwe ngolu lwazi lulandelayo kwindawo ebonakalayo: igama lomvelisi, igama lemveliso, imodeli yemveliso, umhla wokuhlolwa kunye nobungakanani bokupakishwa, nokuba umxholo ophawulweyo uphelelwe okanye uwile.

(2) Khangela ukuba ibhokisi yokupakisha ishicilelwe okanye incanyathiselwe iimpawu zezothutho ezinje ngo "Phatha Ngenkathalo", "Ukoyika Ukumanzi", "Phezulu", njl. ixobulwe.

(3) Khangela ukuba ukupakishwa kwangaphakathi kunye nangaphandle kweemveliso kwibhokisi kunokukhubazeka, ukonakaliswa, ukumanzi okanye ukucudiswa.

(4) Khangela ukuba amaxwebhu akwibhokisi yokupakisha aphelele na. Ubuncinci kufuneka kubekho uluhlu lokupakisha, isatifikethi semveliso, izincedisi kunye namanye amaxwebhu afanelekileyo angenamkhethe.

4.4Ukuhlolwa kwembonakalo kunye nokuhlolwa kwe-dimensional

Indlela yokuhlola okubonwayo isetyenziselwa ukujonga ubume bemveliso, umgangatho wokusetyenzwa kunye nomgangatho womphezulu, kunye nokulinganisa imilinganiselo ukuhlangabezana neemfuno ze-4.3. Kubandakanya kodwa kungaphelelanga koku kulandelayo:

(1) Ingaba iimpawu (iisimboli zesicatshulwa okanye iimpawu zegrafiki) ziyahambelana neemfuno zengcaciso;

(2) Ileyibhile mayingabi nazo naziphi na iziphene ezingafundekiyo (ifiphale, iphuphuma, ayiphelelanga, iqhawulwe);

(3) Ifanele icoceke, ingabi nalungcoliso, ingabi nasiphako, ingabi namonakalo owenziwe ngumatshini;

(4) Imilinganiselo kufuneka ihlangabezane neenkcukacha zobugcisa ezineenkcukacha kunye neemfuno zokunyamezela.

4.5 Uvavanyo lombane

(1) Vula uvavanyo lombane wesiphaluka

(2) Uvavanyo lombane lomthwalo

(3) Uvavanyo lwe-Pulse performance

(4) Uvavanyo lokusebenza lwePassivation (lusebenza kwiibhetri ze-Li-SOCl2)

(5) Uvavanyo lobungakanani bomsebenzi

4.6 Uvavanyo lokusebenza koomatshini

(1) Uvavanyo lwamandla etheminali (lusebenza kwiintlobo ezineetafile zentsimbi)

(2) Uvavanyo lwempembelelo

(3) Uvavanyo lokungcangcazela

4.7 Uvavanyo lokusebenza kwe-soldering

(1) Uvavanyo lwe-Solderability (lusebenza kwiintlobo ezineetafile zentsimbi)

(2) Uvavanyo lokumelana nobushushu (olusebenzayo kwiintlobo ezineentsimbi zokuwelda iithebhu)

4.8 Uvavanyo lokusingqongileyo

(1) Uvavanyo lobushushu bobushushu

(2) Ubushushu obuphezulu kunye novavanyo lokufuma okuphezulu

(3) Uvavanyo lwesitshizi setyuwa

Ngenxa yobuchule obuqinileyo bovavanyo lokhuseleko, ababoneleli kufuneka babonelele ngeengxelo zovavanyo lomntu wesithathu.

(1) Uvavanyo lokulinganisa oluphezulu

(2) Uvavanyo lwesiphaluka esifutshane sangaphandle

(3) Uvavanyo lwempembelelo yento enzima

(4) Uvavanyo lwe-Extrusion

(5) Uvavanyo lokukhutshwa ngenkani

(6) Uvavanyo lokutshaja ngokungaqhelekanga

(7) Uvavanyo lwedrophu yasimahla

(8) Uvavanyo lokusetyenziswa kakubi kwe-thermal

5.Imithetho yokuhlola

5.1 Ukuhlolwa kwefektri

Iyunithi yokuvelisa iya kuqhuba uhlolo lwefektri kwimveliso nganye eveliswe ngokweendlela zovavanyo ezibonelelwe kulo mgangatho wovavanyo. Emva kokuphumelela ukuhlolwa, isatifikethi somgangatho siya kukhutshwa. Ukufumana izinto zokuhlola, jonga kwisihlomelo.

5.2 Ukuhlolwa kwesampulu

Ukuhlolwa kwesampulu kuya kwenziwa ngokuhambelana nendlela yesampulu echazwe kwi-GB/T2828.1 "Inkqubo yokubala iSampuli yoHlolo lweSigaba 1 ISicwangciso sokuHlola iSampulu seBatch-by-batch efunyenwe nguMda woMgangatho woKwamkeleka (AQL)". Ngokwalo mgangatho wovavanyo, izinto zovavanyo zahlulwe zibe ngamacandelo amabini: A kunye no-B. Udidi A luyinto ye-veto, kwaye udidi B aluyiyo i-veto. Ukuba kukho ukungaphumeleli kweCandelo A kwisampuli, ibhetshi iya kugwetywa njengengafanelekanga. Ukuba kukho ukungaphumeleli kweCandelo B kwaye uvavanyo luphumelela emva kokulungiswa, ibhetshi iya kugwetywa njengefanelekile.

5.3 Uvavanyo lokuqinisekisa ngamaxesha athile

Iisampulu zokuqinisekisa rhoqo ziya kuqhutywa ngokuhambelana ne "Periodic Confirmation and Inspection System for Key Materials", kwaye uvavanyo luya kwenziwa ngokuhambelana nezinto zovavanyo, iimfuno zovavanyo kunye neendlela zovavanyo ezichazwe kulo mgangatho wovavanyo ukumisela ukuthotyelwa kovavanyo. iimpawu zemveliso kunye namalungiselelo alo mgangatho wovavanyo.

Ngexesha lovavanyo lokuqinisekisa ngamaxesha, ukuba nayiphi na enye okanye nayiphi na into yesampuli iyasilela, imveliso iya kugwetywa njengengafanelekanga, kwaye iyunithi yokuvelisa iya kwaziswa ngokuqinisekiswa komgangatho kunye nokulungiswa.

5.4 Uvavanyo lwentsebenzo epheleleyo

Uvavanyo ngokwezinto zovavanyo, iimfuno zovavanyo kunye neendlela zovavanyo ezichazwe kulo mgangatho wovavanyo ukumisela ukuthotyelwa kweempawu zemveliso kunye nezibonelelo zalo mgangatho wovavanyo.

Uvavanyo olupheleleyo lokusebenza lufanelekile ukuhlolwa kwesampulu yiyunithi yokuvelisa. Kuvavanyo olupheleleyo lwentsebenzo, ukuba nayiphi na enye okanye nayiphi na into yesampuli iyasilela, imveliso iya kugwetywa njengengafanelekanga.

6 yokugcina

Iimveliso ezipakishwe kakuhle kufuneka zigcinwe kwindawo yokugcina impahla eneqondo lobushushu le-0°C ukuya kuma-40°C, ukufuma okunxulumene ne-RH <70%, uxinzelelo lwe-atmospheric lwe-86kPa ukuya kwi-106kPa, umoya wokungena komoya kwaye akukho zirhasi ezitshabalalisayo.

Isihlomelo A: Imilinganiselo yereferensi

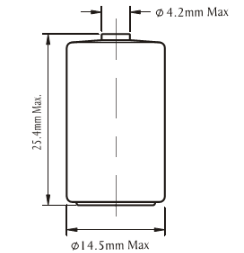

A.1 Ikloko yebhetri (14250)

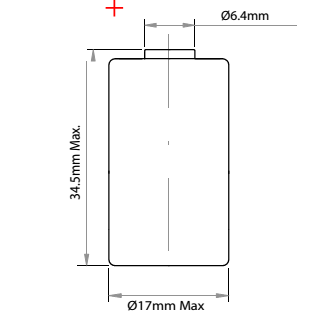

A.2 Ukucima kombane imitha yokufunda ibhetri (CR123A)

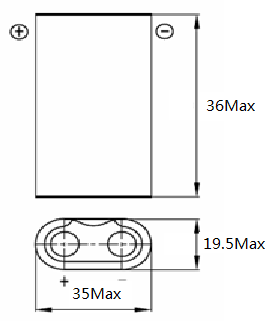

A.3 Ukucima kombane imitha yokufunda ibhetri (CR-P2)

Ixesha lokuposa: Nov-29-2023