Ukhuseleko lwe-excavators ngoomatshini lunxulumene namanyathelo obugcisa okuphelisa okanye ukunciphisa imingcipheko ebangelwa yingozi enkulu, iindawo ezinobungozi okanye iziganeko ezinobungozi ekusebenziseni, ukusebenza kunye nokugcinwa kokwakhiwa komhlaba. Yeyiphi imigangatho yokuhlolwa kwabembi oomatshini? Zihlolwa njani ii-excavators ezingoomatshini?

Mechanical excavator

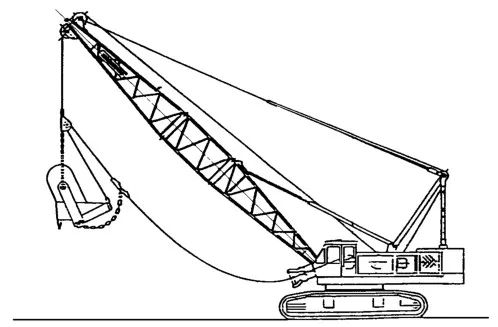

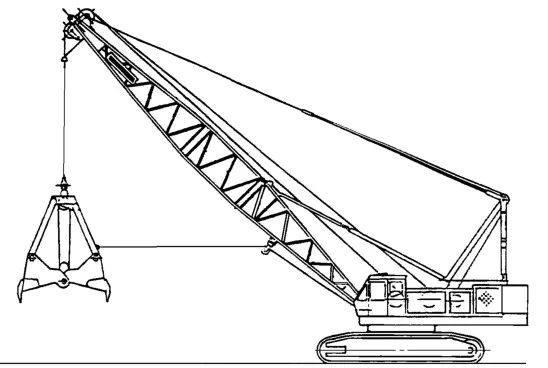

Abembi bezinto zoomatshini babhekisa kubambi abo baphezulu basebenza ngeentambo zocingo. Basebenzisa ubukhulu becala iifotsholo zokurhuqa, iifotsholo zangaphambili okanye ii-emele zokuxhwila kwimisebenzi yokwemba; sebenzisa iipleyiti zetamping ukucofa imathiriyeli; sebenzisa iigwegwe okanye iibhola kwimisebenzi yokutyumza; kwaye usebenzise izixhobo zokusebenza ezikhethekileyo kunye nezincamatheliso. Ukuphatha izinto eziphathekayo.

I-crawler excavator yomatshini enezixhobo zokubamba

Mechanical excavatoriimfuno zomgangatho wokuhlola

01Ukuhlolwa kweMechanical excavator-ukuhlolwa kwendawo yokusebenza yomqhubi

-Izixhobo

Ikhebhu yomqhubi kufuneka ifakwe kwindawo yomqhubi kumatshini wokukhwela.

Oomatshini abanobunzima bokusebenza obungaphezulu kwe-1,500 kg kunye nendawo yomqhubi kufuneka baxhotyiswe ngekhebhu yomqhubi. Oomatshini abanobunzima bokusebenza obungaphantsi okanye obulingana ne-1,500 kg abadingeki ukuba baxhotyiswe ngekhebhu yomqhubi.

Oomatshini bokushukuma komhlaba kufuneka bayilwe ukuze kuqinisekiswe ukuba kufakelwe izixhobo ezifanelekileyo zokukhusela xa zisetyenziswa kwizicelo apho kukho umngcipheko wobutyobo obubhabhayo (umz. ukusebenzisa iihydraulics).

-Indawo encinci yomsebenzi

Esona sithuba sincinci sokushukuma kubaqhubi kufuneka sihambelane ne-ISO 3411.

Ubuncinci besithuba somqhubi kunye nendawo yolawulo kufuneka ihambelane ne-ISO 6682

-Amalungu ashukumayo

Amalungiselelo kufuneka enziwe ukuphepha ukudibana ngengozi kwindawo yomqhubi kunye neendawo ezihambayo ezifana namavili, amabhanti okanye izixhobo zokusebenza okanye izinto eziqhotyoshelweyo.

-Ukuphelelwa kwenjini

Irhasi yokukhupha ephuma kwi-injini kufuneka igcinwe kude nomqhubi kunye ne-air inlet ye-cab

- Ukuthenga kunye nediphozithi yelayisensi yokuqhuba

Indawo kufuneka inikwe kufutshane nendawo yomqhubi ukugcina ngokukhuselekileyo incwadi yomqhubi okanye eminye imiyalelo yokusebenza. Ukuba indawo yomqhubi ayikwazi ukutshixwa okanye akukho cab yomqhubi, isithuba kufuneka sitshixeke.

-Iincam ezibukhali

Akufunekanga kubekho iikona ezibukhali okanye iikona kwindawo yokusebenzela yomqhubi (efana nesilingi, ipaneli yesixhobo sangaphakathi kunye nendlela eya kwindawo yomqhubi).

-Iimeko zemozulu kwindawo yomqhubi

Ikhebhu yomqhubi kufuneka ikhusele umqhubi kwiimeko zemozulu ezimbi ezinokubonwa kwangaphambili. Amalungiselelo eenkqubo zokungenisa umoya, iinkqubo zokufudumeza ezilungelelanisiweyo kunye neenkqubo zokucima iglasi kufuneka zifakwe ngokuhambelana nemimiselo.

-Imibhobho eqinile kunye nemibhobho

Ikhebhu ixhotyiswe ngoxinzelelo lolwelo olukhulu kune-5 MPa okanye ubushushu obungaphezulu kwama-60 C kunye nemibhobho.

-Basic yokungena kunye nokuphuma

Kuya kubonelelwa ngofikelelo olusisiseko, imilinganiselo eya kuthi ihambelane ne-ISO 2867.

-Ukungena nokuphuma ngenye indlela

Enye indlela yokungena/yokuphuma iya kubonelelwa kwicala elahlukileyo ukusuka kwindawo yokuqala yokungena/yokuphuma. Imilinganiselo yayo iya kuhambelana ne-ISO 2867. Oku kunokuba yifestile okanye olunye ucango olunokuvulwa okanye luhanjiswe ngaphandle kwezitshixo okanye izixhobo. Ukuba umnyango unokuvulwa ngaphakathi ngaphandle kwesitshixo okanye izixhobo, sebenzisa i-latch. Iingcango zeglasi ezaphukayo kunye neefestile zobukhulu obufanelekileyo zinokuqwalaselwa njengenye indlela yokuphuma efanelekileyo, ngaphandle kokuba ihamile yokuphuma eyimfuneko ibonelelwe kwikhebhu kwaye ibekwe kwindawo apho umqhubi angafikelela khona.

-Inkqubo yokungenisa umoya

Inkqubo yokungenisa umoya kufuneka ikwazi ukunika umoya omtsha kwikhebhu yomqhubi kunye nesantya sokuhamba esingekho ngaphantsi kwe-43 m / h. Izihluzi ziya kuvavanywa ngokuhambelana ne-SO 10263-2.

-Inkqubo ye-Defrost

Inkqubo yokuphelisa iqhwa kufuneka ibonelele ngezixhobo zokunyibilikisa iifestile zangaphambili nasemva, ezifana nenkqubo yokufudumeza okanye isixhobo esizinikeleyo sokuphelisa iqhwa.

-Inkqubo yokutshaja kakhulu

Ukuba i-cab ene-pressurization system inikezelwa, inkqubo yoxinzelelo iya kuvavanywa ngokuhambelana nemimiselo ye-SO 10263-3 kwaye iya kubonelela ngoxinzelelo lwangaphakathi lwangaphakathi olungekho ngaphantsi kwe-50 Pa.

-Iminyango kunye neefestile

Iingcango, iifestile kunye neeflephu kufuneka zithintelwe ngokukhuselekileyo kwiindawo ezijoliswe kuzo. Iingcango kufuneka zigcinwe kwindawo yazo yokusebenza ekujoliswe kuyo ngezithintelo eziqinileyo ezenzelwe ukugcina ukuvulwa okukhuselekileyo kokungena kwesiseko kunye nokuphuma kwindawo yokusebenza ekujoliswe kuyo, kwaye izithintelo kufuneka zikhutshwe ngokulula kwindawo yomqhubi okanye iqonga lokungena lomqhubi.

Iifestile zeemoto kufuneka zifakwe ngokukhuselekileyo okanye ezinye izinto ezinokusebenza okufanayo kokhuseleko.

Iifestile zangaphambili kufuneka zixhotyiswe ngee wipers zombane kunye ne washers.

Itanki yamanzi yokuhlamba ifestile kufuneka ifikeleleke ngokulula.

-Ukukhanya kwangaphakathi

I-cab yomqhubi kufuneka ixhotyiswe ngesixhobo sokukhanyisa sangaphakathi esisisigxina, ekufuneka sisebenze emva kokuba injini icinyiwe, ukuze indawo yomqhubi ikhanyise kwaye ifunde incwadi yomqhubi.

-Ikhaka elikhuselayo lomqhubi

Abenzi be-Mechanical excavators kufuneka bakwazi ukufaka izakhiwo zokukhusela umqhubi (abagadi abaphezulu kunye nabagadi bangaphambili). Umenzi kufuneka anike izakhiwo zokukhusela (abagadi abaphezulu kunye nabagadi bangaphambili), ekufuneka zikhethwe ngumsebenzisi ngokusekelwe kwimingcipheko ekhoyo yesicelo.

-ISakhiwo soKhuseleko seNto esiwayo (FOPS)

Ngaphandle kwezinxaxhi ezichazwe kwi-ISO3449, iikhreyini ezisikwere ekulindeleke ukuba zisetyenziswe kwiindawo ezineengozi zezinto eziwayo kufuneka ziyilwe ukuze zikwazi ukufakela isakhiwo esikhuselayo sento ewayo (FOPS).

02UHlolo lweMechanical Excavator -Ulawulo lomqhubi kunye nezalathisi

-Qalisa kwaye umise isixhobo

Oomatshini bokushukuma komhlaba kufuneka baxhotyiswe ngezixhobo zokuqalisa nokumisa (ezifana nezitshixo), kwaye inkqubo yokuqalisa kufuneka ixhotyiswe ngezixhobo zokukhusela ukuthintela ukusetyenziswa okungagunyaziswanga.

Oomatshini abashukumayo bomhlaba baya kuyilwa kangangokuba xa injini iqaliswa okanye imisiwe, akunakwenzeka ukuba ushukumise umatshini, izixhobo zokusebenza kunye noncamathiselo ngaphandle kokuqalisa ulawulo.

-Ukusebenza okungalindelekanga

Izixhobo zokulawula ezinokubangela ingozi ngenxa yokusebenza ngengozi kufuneka zilungiswe okanye zivalwe okanye zikhuselwe ngokuhambelana nomgaqo wokunciphisa umngcipheko. Ngokukodwa, xa umqhubi engena kwaye ephuma kwindawo yomqhubi, isixhobo esikhubaza ulawulo kufuneka sizenzele ngokwaso, okanye Sinyanzeliswa ngenkani kwaye sisebenze ngezixhobo ezifanelekileyo.

-i-pedal pedal

Kufuneka kubekho ubungakanani obufanelekileyo, imilo kunye nesithuba esaneleyo phakathi kwabo. Ukunyathela kufuneka kube nendawo engatyibilikiyo kwaye kube lula ukuyicoca. Ukuba iipedals zoomatshini abahamba emhlabeni kunye neepedals zeemoto zinemisebenzi efanayo (i-clutch, i-braking kunye ne-acceleration), ukwenzela ukuphepha ingozi ebangelwa ukuxuba, ii-pedals kufuneka zilungiswe ngendlela efanayo.

-Ukufika ngokungxamisekileyo kweziqhoboshelo

Ukuba injini iyayeka, kuya kwenzeka ukuba:

· Nciphisa isixhobo esisebenzayo/uncamathiselo phantsi/indawo yokubeka;

· Ukwehliswa kweyunithi yomsebenzi/uncamathiselo kubonakala ukusuka kwindawo apho umqhubi avule ulawulo lokwehlisa:

· Ukuphelisa uxinzelelo olushiyekileyo kwisekethe nganye ye-hydraulic kunye ne-pneumatic yezixhobo zokusebenza / izixhobo ezincedisayo ezinokuthi zibangele umngcipheko. Izibonelelo zokunciphisa iziqhotyoshelo kunye neendlela zokususa uxinzelelo olushiyekileyo lunokuthi lube ngaphandle kwendawo yomqhubi kwaye iya kuchazwa kwincwadi yomqhubi.

-Intshukumo engalawulekiyo

Ukushukuma koomatshini kunye nezixhobo zokusebenza okanye uncamathiselo olusuka kwindawo elimisiweyo, ngaphandle kwaxa luqhutywa ngumqhubi, ngenxa yokutyibilika okanye ukucotha (umz. okubangelwa kukuvuza) okanye xa unikezelo lombane luphazamisekile, luya kulawulwa ngaphakathi kuluhlu olungadali mngcipheko. kubantu abatyhilekileyo.

-Imiboniso ebonakalayo / iiphaneli zokulawula, izikhombisi kunye neempawu

· Umqhubi kufuneka akwazi ukubona imiqondiso eyimfuneko yokusebenza kwesiqhelo komatshini kwindawo yomqhubi, emini okanye ebusuku. Ilitha kufuneka lincitshiswe.

· Izalathisi zokulawula ukusebenza okuqhelekileyo kunye nokhuseleko lomatshini kufuneka zihambelane namalungiselelo e-ISO 6011 kukhuseleko nemiba enxulumene noko.

· Iimpawu zomboniso/izixhobo zokulawula kumatshini wokushukuma komhlaba ziya kuthobela izibonelelo ze-ISO 6405-1 okanye i-S 6405-2, njengoko kusebenza.

- Izixhobo zokulawula zoomatshini bokukhwela ezingajoliswanga ukuba zisebenze ukusuka emhlabeni ziya kubonelelwa ngeendlela zokunciphisa ukuphakamisa isixhobo sokulawula ukusuka phantsi.

- Oomatshini bokungakhweli kufuneka baxhotyiswe ngesixhobo sokusebenza sokubamba esimisa ukusebenza komatshini kunye nokuhamba okuyingozi kwesixhobo xa umqhubi ekhupha ulawulo. Ulawulo kufuneka luyilwe ukuba luthathele ingqalelo umngcipheko wokuhamba ngengozi komatshini ukuya kumsebenzisi.

03Ukuhlolwa kweMechanical excavator-ukuhlolwa kwenkqubo yokulawula

- Isixokelelwano sokuqhuba kufuneka siqinisekise ukuba indlela yokuqhuba iyahambelana nendlela ekujoliswe kuyo echazwe kuyoISO 10968.

- Oomatshini abagqunywe ngebhanti abaya phambili/babuyela umva Inkqubo yokulawula yomatshini ogqunywe ibhanti ohamba ngesantya esingaphezu kwe-20 km/h kufuneka ibethambile.

04Ukuhlolwa kweMechanical excavator-ujingi wokuhlolwa kwenkqubo yebrake

Abenzi bemigodi abangoomatshini kufuneka baxhotyiswe ngokusebenza ngokujingi kunye neenkqubo zokuqhobosha zokupaka.

05Ukuhlolwa kweMechanical excavator-ukuhlolwa kwenkqubo yokuphakamisa

- Ulawulo olunyanzelweyo (ukunyusa/phantsi)

Inkqubo yokuphakamisa i-excavator yomatshini kufuneka ixhotyiswe ngebhuleki. I-brake kufuneka isebenze ngokukhawuleza emva kokukhulula isiphatho okanye i-pedal. Inkqubo ye-braking kufuneka isebenze ngokuzenzekelayo xa kwenzeka ukulahlekelwa kwamandla okanye ukunyanzeliswa kokulawula ukuhla, kwaye akufanele kuchaphazele ukuzinza komsebenzi we-excavator. I-Braking Inkqubo kufuneka ikwazi ukugcina umthwalo olinganisiweyo ochazwe kwi-4.8

-Umsebenzi wokuwa wasimahla

Isixokelelwano sokuphakanyiswa kwe-excavator yomatshini iya kuxhotyiswa nge-brake kwaye iya kuqaliswa ngokukhawuleza phantsi kwale miqathango ilandelayo:--Ukusebenza okuhambelanayo kweenyawo zonyawo;

Khulula intambo yesandla.

Iziqhoboshi ziyakuyilwa ukunika uqhoboshelo oluqhubekayo lomthwalo oshukumayo.Isikhokelo kufuneka siyilwe ukunqanda intambo yocingo ekunyukeni okanye ukuwa ngaphandle kolawulo.

-Tshintsha

Xa utshintshela ekusebenzeni ngokunyanzeliswa kokulawula ukuya kwi-free drop operation, akufanele kubekho ukuhla komthwalo.

-boom

I-boom ye-excavator yomatshini kufuneka ikhuselwe ekubuyeleni kwakhona kwimeko yokothula ngequbuliso. I-boom kufuneka ixhotyiswe ngomda wokutshintsha ukunqanda ukulayisha umva.

Ukudibanisa (iibholithi) phakathi kwamacandelo ahlukeneyo e-boom kufuneka kuyilwe ukuvumela ukufakela kunye nokususwa ngaphandle kwesidingo sabasebenzi ukuba bame phantsi kwe-boom.

-Intambo yocingo

Umba wokhuseleko lwentambo yocingo lwe-excavator kufuneka imiselwe.

-Igubu lentambo kunye nepuli yeentambo zocingo

· Uyilo kunye nokwenziwa kwamagubu eentambo zocingo kunye neepuli zeentambo kufuneka zithintele umonakalo kwintambo yocingo kunye nokutyibilika okanye ukuqhawuka kwesikhokelo sentambo yocingo.

· Umlinganiselo wedayamitha yegubu lentambo ukuya kwidayamitha yentambo yocingo kufuneka ubuncinane ibe yi-20:1.

• Umyinge wedayamitha yentambo yentambo yocingo ukuya kwidayamitha yentambo yocingo elinganiswe kwintlambo yentambo kufuneka ubuncinane ibe yi-22:1. Izikhokelo zotsalo, iipuli zesikhokelo kunye neentambo zocingo ezincedisayo azibandakanywa.

· I-crimping rim, umda we-winch drum kufuneka ube ubuncinane amaxesha angama-1.5 ububanzi bentambo yocingo.

06Ukuhlolwa kweMechanical excavator-uthintelo isixhobo sokuhlolwa

-Layisha umda mzuzu

Kwiimeko zokuphatha izinto, inkqubo yokunyusa kunye ne-boom hoisting system kufuneka ixhotyiswe ngesithinteli somzuzu womthwalo ukuphepha ukulayisha ngaphezulu. Umlinganiselo womzuzu womthwalo kufuneka umiselwe kumthwalo olinganisiweyo ochazwe kwi-4.8, kunye nokunyamezela kwe-10%. Emva kokuba isithinteli somzuzu womthwalo sisebenza, umzuzu womthwalo kufuneka uncitshiswe. 4.7.2 Phakamisa isitshixo somda.

Kwiimeko zokuphatha izinto, i-excavators mechanical kufuneka ixhotyiswe ngokutshintshela umda wokunyusa ukunyakaza. Emva kokuba isitshixo somda sivuliwe, i-boom kufuneka ikwazi ukuthoba.

-Umda wokutshintsha inkqubo ye-boom lift

Inkqubo yokuphakamisa i-boom ye-excavator yomatshini kufuneka ixhotyiswe ngomda wokutshintsha ukunqanda ukulayishwa okubuyela umva kwe-boom. Emva kokuba isitshixo somda sivuliwe, i-boom kufuneka ikwazi ukuthoba.

07Ukuhlolwa kweMechanical excavator-ukuhlolwa kozinzo

- Oomatshini bokushukuma komhlaba abanezixhobo zokusebenza kunye noncamathiselo, kubandakanywa izixhobo ezikhethiweyo, eziyilwe kwaye zenziwe ziya kubonelela ngozinzo olwaneleyo phantsi kokugcinwa, ukudibanisa, ukuchithwa kunye neemeko zokusebenza zothutho ezichazwe ngumvelisi kwincwadana yemigaqo yomqhubi. Izixhobo ezisetyenziselwa ukunyusa uzinzo koomatshini bokushukuma komhlaba kwimo yokusebenza kufuneka zifakelwe isivalo esiqhagamshelweyo okanye esinendlela enye ukuze sibambe umbhobho endaweni ukuba uyasilela okanye uzaliswe yioyile.

- Ibhakethi yotsalo, umthamo wokusebenza we-excavator yomatshini ekusebenzeni komda wokutsala uya kuba mncinci kwezi zimbini zilandelayo:

a) I-75% yomthwalo obhukuqayo obaliweyo P;

b) Esona sixhobo siphezulu sokuphakamisa iwintshi.

Ulungelelwaniso lobungakanani bebhakethi yokutsala iya kumiselwa ngumvelisi

-Ukubambana kunye nomhlakulo

Umthamo wokusebenza we-excavator yomatshini ekubambeni kunye neemeko zefosholo kufuneka zibe ncinane kwezi zimbini zilandelayo:

· Ngokusekelwe kwi-66% yomthwalo obhukuqiweyo obaliweyo P;

· Esona sixhobo siphezulu sokuphakamisa iwintshi.

Ukulinganiswa komthamo wefosholo kuya kumiselwa ngokuhambelana ne-ISO 7546 kunye nokulinganisa umthamo webhakethi lokubamba kuya kumiselwa ngumenzi.

Ixesha lokuposa: Dec-19-2023