Imigangatho yesizwe enyanzelekileyo kunye ne-IEC zinayoiimfuno zobugcisangokumakishwa, ukhuseleko lokuchasa ukothuka, ulwakhiwo, ukusebenza kombane, ukusebenza koomatshini, njl.njl. iiplagi kunye neziseko zendlu kunye neenjongo ezifanayo. Oku kulandelayo yimigangatho yokuhlola kunye neendlela zeeplagi kunye neziseko.

Iplagi kunye nokuhlolwa kweesokethi

1. Ukuhlolwa kwembonakalo

2. Ukuhlolwa komgangatho

3. Ukukhuselwa ngokuchasene nokothuka kombane

4. Amanyathelo omhlaba

5. Iitheminali kunye nezihloko

6. Ubume besokethi

7. Ukuguga-ukumelana kunye nobungqina bokufuma

8. Ukumelana ne-insulation kunye namandla ombane

9. Ukunyuka kobushushu

10. Ukuqhawula amandla

11. Ukusebenza okuqhelekileyo (uvavanyo lobomi)

12. Ukutsalwa ngaphandle kwamandla

13. Amandla omatshini

14. Uvavanyo lokumelana nobushushu

15. Izikrufu, iindawo eziphetheyo ngoku kunye nokudibanisa kwazo

16. Umgama weCreepage, imvume yombane, umgama wokutywina wokungena kokungena

17. Ukumelana nokushisa okungaqhelekanga kunye nokumelana nomlilo wezinto zokukhusela

18. Ukusebenza kwe-Anti-rust

1. Ukuhlolwa kwembonakalo

1.1 Amalungu aphambili emveliso kufuneka abe nala manqaku alandelayo:

-Ikalwe ngoku (i-amps)

-Ixabiso lombane (iivolthi)

- Isimboli yonikezelo lwamandla;

-Igama, uphawu okanye uphawu lokuzazisa lomenzi okanye umthengisi;

Inombolo yemveliso

-Inqaku lesatifikethi

1.2 Iisimboli ezichanekileyo mazisetyenziswe kwimveliso:

1.3 Kwiisokethi ezizinzileyo, oku makishiyo kulandelayo kufuneka kumakishwe kumacandelo aphambili:

-Ireyithwe ngoku, amandla ombane kunye neepropati zobonelelo lwamandla;

-Igama okanye uphawu okanye uphawu lokwazisa umenzi okanye umthengisi;

-Ubude be-insulation okufuneka buhlulwe ngaphambi kokuba umqhubi ufakwe kwi-terminal e-screwless (ukuba ikhona);

- Ukuba i-socket ifanelekile kuphela ukudibanisa iingcingo ezinzima, kufuneka kubekho uphawu lokuba i-screwless terminal ifanelekile kuphela ukudibanisa iingcingo ezinzima;

Inombolo yemodeli, enokuthi ibe yinombolo yekhathalogu.

1.4 Umgangatho wembonakalo: Umphezulu wesokethi kufuneka ube mpuluswa, igobolondo kufuneka ifane, kwaye kungabikho pores, iintanda, ii-indentations, amaqhuma, umonakalo, amabala, okanye ubumdaka; iindawo zetsimbi akufanele zibe ne-oxidation, amabala e-rust, i-deformation, ukungcola, kunye ne-coating kufuneka ifane kwaye ikhanyise.

1.5 Ukupakishwa: Igama lemveliso, iinkcukacha, ikhowudi yezinto eziphathekayo, igama lomzi-mveliso, ubuninzi, kunye nenombolo yebhetshi yokuvelisa kufuneka imakishwe kwibhokisi yokupakisha.

2. Ukuhlolwa komgangatho

2.1 Isokethi mayifakwe kwaye ikhutshwe amaxesha ali-10 ngeplagi enesayizi enkulu yephini ehlangabezana neemfuno zomgangatho ohambelanayo. Ubungakanani bepini buhlolwe ngokulinganisa okanye ukusebenzisa i-gauge.

2.2 Kwisistim enikiweyo, iplagi mayingadibani nezi socket-outlets zilandelayo:

-Iisokethi ezinemilinganiselo ephezulu yombane okanye imilinganiselo ephantsi yangoku;

-Iiziseko ezinamanani ahlukeneyo e-electrode;

3.Pukukhuseleka ngokuchasene nokothuka kombane

3.1 Xa iplagi ifakwe ngokupheleleyo kwisokethi, iindawo ezihlala iplagi kufuneka zingabikho. Jonga ukuba ifanelekile na ngokuhlolwa. Iiplagi ezizinzileyo, iiplagi ezidityanisiweyo kunye neendawo zokuphuma eziphathwayo ziya kwakhiwa kwaye ziyilwe kangangokuba, xa zifakwe okanye zifakwe iintambo zokusetyenziswa okuqhelekileyo, iindawo eziphilayo azifumaneki nasemva kokususwa kwezo ndawo zifikelelekayo ngaphandle kwezixhobo. Okufanayo kuya kwiindawo ezinokususwa.

3.2 Xa izixhobo zombane zifakwe iingcingo kwaye zifakwe ngokweemfuno zokusetyenziswa eziqhelekileyo, zisafikeleleka, ngaphandle kwezikrufu ezincinci kunye neendawo ezifanayo ezisetyenziselwa ukulungisa iindawo eziphambili kunye nezigqubuthelo kunye nezigqubuthelo zesokethi, ezahlulwe kwi-live. iinxalenye. Kufuneka zenziwe ngezinto zokukhusela. impahla.

3.3 Nayiphi na iphini yeplagi ayinakuhlangana nesokethi ephilayo yesokethi xa nayiphi na enye iphini ikwimo yokufikeleleka.

3.4 Amalungu angaphandle eplagi aya kwenziwa ngezinto ezigqumayo. Oku akubandakanyi iindawo ezifikelelekayo ezifana nezikrufu zokudityaniswa, izikhonkwane ezithwalayo ngoku, izikhonkwane zokumisa, iintsimbi zokumisa, kunye nezangqa zentsimbi ezijikeleze izikhonkwane.

3.5 Isokhethi enomnyango okhuselayo, xa iplagi ikhutshwe, i-socket ephilayo inokukhuselwa ngokuzenzekelayo.

3.6 Umkhono osezantsi wesokethi awufanele ukhubazeke ngendlela ebeka emngciphekweni ukhuseleko ngenxa yokufakelwa kweplagi.

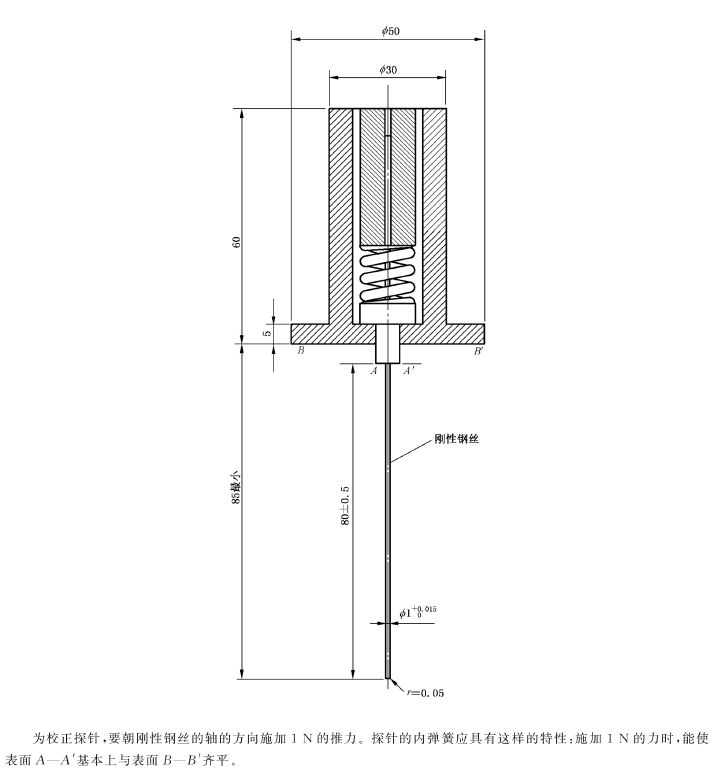

3.7 Iziseko ezinokhuseleko oluphuculweyo, xa zifakwe kwaye zifakwe iingcingo ngokweemfuno zokusetyenziswa ngokuqhelekileyo, iindawo eziphilayo kufuneka zifikeleleke nge-1 mm ububanzi beprobe. Njengoko kubonisiwe ngezantsi:

4. Amanyathelo omhlaba

4.1 Xa iplagi ifakwe, i-pin yokumisa kufuneka iqhagamshelwe kwisiseko somhlaba kuqala, kwaye i-pin-carrying pin kufuneka inikwe amandla. Xa iplagi isusiwe, isikhonkwane esiphetheyo sangoku kufuneka siqhawule phambi kokuba isikhonkwane somhlaba siqhawule.

4.2 - Ubungakanani betheminali esezantsi buya kufana nobungakanani betheminali yekhondatha yamandla ehambelanayo.

- Itheminali yomhlaba yezincedisi zombane ezinokuphinda zisebenze ezinoqhagamshelwano lomhlaba iya kuba yangaphakathi.

- Itheminali yomhlaba ye-socket-outlet esisigxina iya kumiselwa kwisiseko okanye kwicandelo eligxininiswe ngokuqinileyo kwisiseko.

- Umkhono wokumisa we-socket-outlet esisigxina uya kugxilwa kwisiseko okanye kwi-cover. Ukuba igxininiswe kwisigqubuthelo, umkhono wokumisa uya kuqhagamshelwa ngokuzenzekelayo nangokuthembekileyo kwitheminali yokumisa xa isigqubuthelo sikwindawo yaso yesiqhelo. Abafowunelwa kufuneka bafakwe isilivere okanye babe nomhlwa kwaye banxibe ukuxhathisa okungekho ngaphantsi kwesilivere epleyitiweyo.

4.3 Kwiisokethi ezisisigxina ezineziseko ezisezantsi, iindawo zetsimbi ezifikelelekayo eziza kuphila xa i-insulation ihluleka kufuneka igxininiswe ngokusisigxina kwaye ikhuseleke ngokukhuselekileyo kwi-terminal yokumisa.

4.4 I-socket-outlet enekhowudi ye-IP ephezulu kune-IPXO kunye ne-insulating ene-cable yokungena engaphezulu kwesinye iya kuxhotyiswa ngeetheminali zomhlaba ezisisigxina zangaPhakathi, okanye ibonelele isithuba esaneleyo seetheminali ezidadayo, ivumele uqhagamshelo olungenayo noluphumayo ukuqinisekisa ukuqhubeka kwe-terminal yomhlaba. isekethe yomhlaba.

4.5 Ukudibanisa phakathi kwe-terminal yomhlaba kunye neengxenye zetsimbi ezifikeleleke ngokulula kufuneka zibe yi-low-resistance connection, kwaye ukuchasana akufanele kube mkhulu kune-0.05Ω.

4.6 Izixhobo zombane ezizinzileyo ezijolise ekuboneleleni ngesekethe ekhuselayo kuphazamiseko lombane xa isixhobo esiqhagamshelwe kuso siya kuxhotyiswa ngesokethi esezantsi kwaye iitheminali zayo ziya kwahlulwa ngombane nakweyiphi na into exhonywa ngesinyithi okanye kumhlaba okhuselayo onokuthi iqhagamshelwe kwisixokelelwano. umbane wedwa kwezinye iindawo eziqhutywayo ezivelileyo zesekethe.

5.Iitheminali kunye nezihloko

5.1 Iisokethi ezizinzileyo ezibuyiselwayo ziya kuxhotyiswa ngeetheminali ezine-screw-clamped or screwless terminals.

5.2 Iiplagi ezivuselelekayo kunye neendawo zokuphuma eziphathwayo eziphathwayo ziya kuxhotyiswa ngeetheminali ezinemisonto ebambekayo.

5.3 Ukuba iintambo ezifakwe ngaphambili zisetyenzisiwe, kufuneka kuqatshelwe ukuba kwii-terminals ze-screw-type, indawo esele ifakwe ngaphambili kufuneka ibe ngaphandle kwendawo yokudibanisa xa idibaniswe ekusebenziseni okuqhelekileyo.

5.4 Nangona iindawo ezisetyenziselwa ukubamba ii-conductors kwitheminali zinokusetyenziselwa ukugcina i-terminal ikwimo yesiqhelo okanye ukuthintela i-terminal ekujikelezeni, mayingasetyenziselwa ukulungisa nawaphi na amanye amalungu.

5.3 Itheminali yohlobo lwe-thread clamp

-Iitheminali zokudibanisa ezinemisonto kufuneka zikwazi ukudibanisa abaqhubi abangaphathwanga;

- Iitheminali zokubamba imisonto kufuneka zibe namandla aneleyo omatshini kwaye akufunekanga zenziwe ngentsimbi ethambileyo okanye intsimbi ethanda ukurhubuluza;

- Iitheminali zokubamba imisonto kufuneka zixhathise ukubola; i-thread clamping terminals akufuneki yonakalise ngokugqithisileyo abaqhubi xa beyibamba;

-Iitheminali zokudibanisa ezinemisonto zinokuqinisa ngokuqinileyo umqhubi phakathi kweendawo ezimbini zetsimbi;

-I-terminal ye-thread clamping, xa uqinisa i-screw okanye i-nut, akunakwenzeka ukuba iingcingo zomqhubi we-hard-core conductor okanye umqhubi odibeneyo ukuba aphume;

-Iitheminali zohlobo lwe-thread clamp ziya kulungiswa kwiplagi kunye nesokethi ngendlela yokuba izikrufu ezibambezelayo okanye amandongomane angakwazi ukuqiniswa okanye akhululwe ngaphandle kokubangela ukuba i-terminal ngokwayo ikhululeke.

- I-clamping screws kunye namandongomane eetheminali zomhlaba zohlobo lwe-thread-clamp kufuneka zitshixeke ngokwaneleyo ukuphepha ukukhulula ngengozi; kwaye kufuneka ingabinazixhobo.

-Iitheminali zomhlaba zohlobo lwe-thread clamp ziya kuba ngohlobo lokuba kungabikho mngcipheko womhlwa ovela kuqhagamshelwano phakathi kwala malungu kunye neconductor yomhlaba yobhedu okanye ezinye iintsimbi ezidibana nayo.

5.4 Iitheminali ezingenasikrufu zeekhondakhtha zobhedu zangaphandle

- Iitheminali ezingenasikrwelo zinokuba luhlobo olulungele kuphela iikhondakhtha zobhedu oluqinileyo, okanye zohlobo olulungele zombini iikhondaktha zekopolo eziqinileyo nezithambileyo.

- Iitheminali ezingenasikrwerha ziya kuba nakho ukuqhagamshela izikhondatha ezingakhange zilungiswe ngokukodwa.

-Iitheminali ezingenamsonto kufuneka zikhuselwe ngokufanelekileyo kwisokethi. Iitheminali ezingenasikrwelo akufuneki zikhululeke ngenxa yoqhagamshelo okanye ukuqhawuka kwee-conductor ngexesha lofakelo.

-Iitheminali ezingenamisonto ziya kukwazi ukumelana noxinzelelo lomatshini olwenzeka ngexesha losetyenziso oluqhelekileyo.

-Iitheminali ezingenantambo ziya kukwazi ukumelana noxinzelelo lombane kunye nobushushu olwenzeka ngexesha lokusetyenziswa kwesiqhelo.

6.1 Amalungu omkhono wesokethi kufuneka abe elastiki ngokwaneleyo ukuqinisekisa uxinzelelo olwaneleyo lokunxibelelana ngokuchasene nezikhonkwane zeplagi.

6.2 Amalungu endibano ye-socket-outlet adityaniswe nezikhonkwane zeplagi kwaye asetyenziselwa ukufikelela kuqhagamshelo lombane xa iplagi ifakwe ngokupheleleyo kwisokethi iya kuqinisekisa ukuba kukho udibaniso lwesinyithi ubuncinane kumacala amabini achaseneyo ngalinye. iphini.

6.3 Umkhono wesokethi kufuneka uxhathise ukubola kunye nokuguga.

6.4 Iimfuno ze-insulating liners kunye nezithintelo zokugquma.

6.5 I-socket-outlet iya kwakhiwa ukuququzelela ukufakwa kwee-conductors kunye noqhagamshelo olululo kwiitheminali, ukubekwa ngokufanelekileyo kwee-conductors, ukukhululeka kokukhusela amacandelo amakhulu eludongeni okanye kwibhokisi, kunye nendawo eyaneleyo.

6.6 Uyilo lwe-socket-outlet akufuneki luthintele ukuhlangana ngokupheleleyo kunye neplagi efanelekileyo ngenxa yazo naziphi na iiprotrusions ezivela kumphezulu wokukhwelana. Xa iplagi ifakwe kwi-socket, inqunywe ngokulinganisa ukuba i-gap phakathi kwe-mating surface yeplagi kunye ne-socket mating surface akufanele idlule i-1mm.

6.7 Iphini lokumisa kufuneka libe namandla aneleyo omatshini.

6.8 Isiseko sesiseko, isiseko sesigaba kunye nesokhethi engathathi hlangothi kufuneka itshixiwe ukuthintela ukujikeleza.

6.9 Iintambo zetsimbi zesekethe yomhlaba akufanele zibe naziphi na iibhula ezinokonakalisa i-insulation ye-conductors yamandla.

6.10 Iisokethi ezifakwe kwiibhokisi zofakelo ziya kuyilwa ukwenzela ukuba i-conductor iphela iqhutywe emva kokuba ibhokisi yokufakela ifakwe kwindawo eqhelekileyo kodwa ngaphambi kokuba i-socket ifakwe kwibhokisi yokufakela.

6.11 Iindlela zokungena ngeekhebhula kufuneka zivumele ukungena kwee-conduits zentambo okanye iisheaths ukunika ukhuseleko olupheleleyo ngoomatshini kwiintambo.

7. Ukuguga-ukumelana kunye nobungqina bokufuma

I-7.1 I-socket kufuneka ibe nokuchasana nokuguga: emva kokuba isampuli ibonakaliswe kwi-oven yokushisa ye-70 ℃ ± 2 ℃ kwiiyure ze-168, isampuli ayiyi kuba nokuqhekeka kwaye izinto zayo aziyi kuba zinamathele okanye zityibilike.

I-7.2 I-socket kufuneka ibe nobungqina bomswakama: emva kokuba isampuli igcinwe kwiiyure ezingama-48 kwi-humidity ehambelana ne-91% ~ 95% kunye nokushisa kwe-40 ℃ ± 2℃, ukuxhathisa ukugquma kunye namandla ombane kufuneka kuhambelane nemimiselo.

8. Ukumelana ne-insulation kunye namandla ombane

8.1 Ukuxhatshazwa kwe-insulation phakathi kwazo zonke izibonda ezixhunyiwe kunye nomzimba ngu-≥5MΩ.

8.2 Ukuxhatshazwa kwe-insulation phakathi kwazo zonke iipali ≥2MΩ.

8.3 Faka uvavanyo lokumelana nombane we-50Hz, 2KV~ phakathi kwawo onke amacandelo ngomzuzu omnye. Akufuneki kubekho ukuqhwanyaza okanye ukwaphuka.

9. Ukunyuka kobushushu

Emva kokuba isampuli iphumelele uvavanyo lobomi, ukunyuka kweqondo lokushisa kwee-terminals zayo akufanele kudlule i-45K, ukunyuka kweqondo lokushisa eliphezulu kweendawo zetsimbi ezifikelelekayo akufanele kudlule i-30K, kunye nokunyuka kweqondo lokushisa kweengxenye ezingezizo zetsimbi akufanele kudlule i-40K.

10. Ukuqhawula amandla

Kwizincedisi zombane ezinomthamo olinganisiweyo ongekho ngaphezulu kwe-250 V kunye nenqanaba langoku elingekho ngaphezulu kwe-16 A, ukubetha kwesixhobo sovavanyo kufuneka kube phakathi kwe-50 mm kunye ne-60 mm.

Faka iplagi ngaphakathi nangaphandle kwisokethi amaxesha angama-50 (i-100 imivumbo), iplagi-in kunye nesantya sokukhupha:

- Kwizincedisi zombane ezinomlinganiselo wangoku ongekho mkhulu kune-16 A kunye ne-voltage elinganisiweyo engekho ngaphezu kwe-250V, imivimbo engama-30 ngomzuzu;

-Kwezinye izixhobo zombane, ii-15 izibetho ngomzuzu.

Ngexesha lovavanyo, akukho flash ye-arc ezinzileyo kufuneka yenzeke. Emva kovavanyo, umboniso uya kukhululeka kumonakalo oza kuchaphazela ukusetyenziswa okungaphezulu, kwaye umngxuma wokufaka isikhonkwane uya kukhululeka kumonakalo onokuchaphazela ukhuseleko lwayo ngaphakathi kwentsingiselo yolu xwebhu.

11. Ukusebenza okuqhelekileyo (uvavanyo lobomi)

Izixhobo zombane kufuneka zikwazi ukumelana noxinzelelo lomatshini, umbane kunye nobushushu obuvela kusetyenziso oluqhelekileyo ngaphandle kokunxiba ngokungafanelekanga okanye ezinye iziphumo eziyingozi. Kwisekethe ene-voltage elinganisiweyo, i-current rated, i-COSφ=0.8±0.05, iplagi kunye nokukhupha amaxesha angama-5000.

Ngexesha lovavanyo, akukho flash ye-arc eqhubekayo kufuneka yenzeke. Emva kovavanyo, umzekelo akufanele ubonise: ukunxiba okuya kuchaphazela ukusetyenziswa kwexesha elizayo; ukuwohloka kwezindlu, ii-gaskets ezikhuselayo okanye izithintelo, njl. umonakalo kwisokhethi eya kuchaphazela ukusebenza okuqhelekileyo kweplagi; uqhagamshelo lombane oluxengaxengayo okanye oomatshini; ukuvuza kwe-sealant. ukuvuza.

12. Ukutsalwa ngaphandle kwamandla

Isokhethi kufuneka iqinisekise ukuba iplagi ilula ukuyifaka kwaye isuse kwaye ithintele iplagi ekuphumeni kwisokethi ngexesha lokusetyenziswa okuqhelekileyo.

13. Amandla omatshini

Izixhobo zombane, iibhokisi zokufakela ezixhonywe phezulu, amadlala anemisonto kunye nezigqubuthelo kufuneka zibe namandla aneleyo omatshini ukumelana noxinzelelo lomatshini olwenziwa ngexesha lofakelo kunye nokusetyenziswa.

14.Uvavanyo lokumelana nobushushu

14.1 Isampuli ishushu kwi-oven ye-100 ° C ± 2 ° C ngeyure eli-1. Ngethuba lovavanyo, isampuli akufanele iqhube utshintsho oluya kuchaphazela ukusetyenziswa kwexesha elizayo, kwaye ukuba kukho i-sealant, akufanele ihambe ukuze iveze iindawo eziphilayo. Emva kovavanyo, uphawu kufuneka luhlale lufundeka.

14.2 Emva kovavanyo loxinzelelo lwebhola, i-diameter ye-indentation ayiyi kuba ngaphezu kwe-2mm.

15. Izikrufu, iindawo eziphetheyo ngoku kunye noqhagamshelo lwazo

15.1 Zombini uqhagamshelo lombane kunye noomatshini kufuneka lumelane noxinzelelo lomatshini olwenzeka kusetyenziso oluqhelekileyo.

15.2 Kwizikrufu ezibandakanya imisonto yezinto zokugquma kunye nezikrufu ekufuneka ziqiniswe xa udibanisa izixhobo zombane ngexesha lofakelo, qinisekisa ukuba zikhokelwe ngokuchanekileyo kwimingxuma yesikrufu okanye imantongomane.

15.3 Uqhagamshelo lombane kufuneka lube lolokuba uxinzelelo loqhagamshelwano aludluliswa ngesixhobo sokugquma.

15.4 Izikrufu kunye neerivethi kufuneka zitshixiwe xa udibanisa umbane kunye noqhagamshelo ngoomatshini ukuthintela ukukhulula kunye nokujikeleza.

15.5 Izixhobo eziphethe isinyithi kufuneka zenziwe ngetsimbi ezihlangabezana neemfuno zamandla omatshini, ukuqhutyelwa kombane kunye neempawu zokubola.

15.6 Abafowunelwa abaya kutyibilika ngexesha lokusetyenziswa kwesiqhelo kufuneka benziwe ngentsimbi enganyangekiyo kukutya.

15.7 I-self-tapping kunye nezikrufu zokuzisika aziyi kusetyenziselwa ukudibanisa iindawo eziphethe ngoku. Zisenokusetyenziselwa ukudityaniswa komhlaba, ngaphandle kokuba kusetyenziswe izikrufu ezibini.

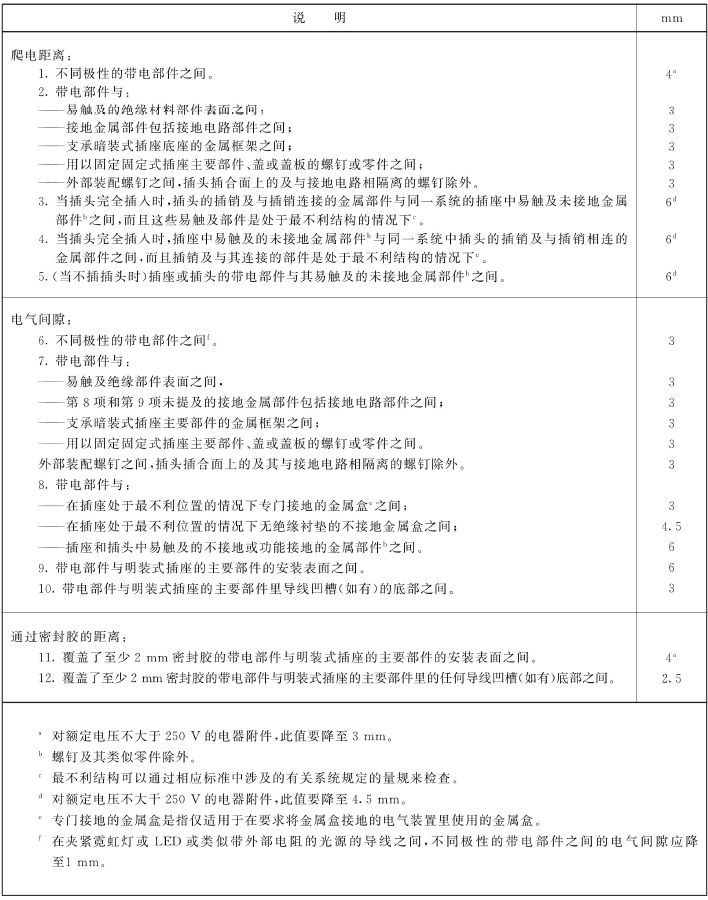

16. Umgama ovulekayo, ukucocwa kombane, ngomgama wokutywina wokuvalwa

Umgama weCreepage, ukukhutshwa kombane kunye nomgama phakathi kwe-sealant yimi ngolu hlobo lulandelayo:

I-17.Ukushisa okungaqhelekanga kunye nokumelana nomlilo wezinto zokukhusela

17.1 Uvavanyo locingo olukhazimlayo (luvavanywa ngokuhambelana negatya lesi-4 ukuya kwele-10 le-BS6458-2.1:1984) Izinto ezigqumayo zeendawo eziphathwayo zangoku kunye neenxalenye zesekethe ezisekelwe phantsi 850℃

17.2 Izinto ezigqumayo zeendawo ezingaguqukiyo eziphetheyo zangoku kunye neengxenye zesekethe eziphantsi kwe-650 ℃.

17.3 Emva kovavanyo, akukho mlilo ubonakalayo kwaye akukho kukhanya okuqhubekayo, okanye ilangatye licinywa okanye ukukhanya kulahlekile kwimizuzwana engama-30 emva kokuba ucingo oluvuthayo lususiwe; iphepha le-tissue alibambi umlilo, kwaye ibhodi yepine ayitshi.

18. Ukusebenza okuchasene nomhlwa

Iindawo zentsimbi aziyi kubonakalisa umhlwa emva kokuphumelela uvavanyo lokutya.

Ixesha lokuposa: Feb-05-2024