Njengoba isimo sezulu sishisa futhi izinga lokushisa likhuphuka, izingubo ziba mncane futhi ziguge. Ngalesi sikhathi, ikhono lokuphefumula lezingubo libaluleke kakhulu! Isiqephu sezingubo esinamandla okuphefumula kahle singahwamulisa umjuluko emzimbeni, ngakho-keikhono lokuphefumula lendwanguihlobene ngokuqondile nenduduzo yendwangu.

Ukusetshenziswa kwekhono lokuphefumula embonini yendwangu

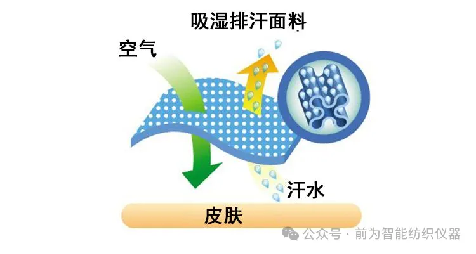

Imboni yezimpahla zokugqoka: Ikhono lokuphefumula lingenye yezinkomba ezibalulekile zokuhlola ukunethezeka kwezindwangu. Ikakhulukazi lapho uklama izingubo zezemidlalo zangaphandle, izicathulo zezemidlalo neminye imikhiqizo, kuyadingeka ukuqinisekisa ukuthi zinganikeza ikhono elihle lokuphefumula ngokuhlolwa kwekhono lokuphefumula ukuze kuzuzwe ukumuncwa komswakamo nokujuluka. , Gcina umphumela owomile.

Izindwangu zasekhaya: imikhiqizo efana nokulala, amakhethini, izembozo zefenisha, njll. Ukuhlola ukungena komoya kungasetshenziswa ukuze kutholwe ukungena komoya kwale mikhiqizo bese kuhlolwa ukunethezeka nokusebenziseka kwayo.

Izimpahla zokwelashwa: Izindwangu zezokwelapha ezifana nezingubo zokuhlinza kanye nemaski zidinga ukuba nekhono elihle lokuphefumula ukuze kuqinisekiswe ukuthi abasebenzi bezokwelapha bangahlala benethezekile endaweni yokusebenza yesikhathi eside. Ngokuhlola ikhono lokuphefumula, ukusebenza kokushintshisana kwegesi komkhiqizo kunganqunywa ukuvimbela izifo ezibangelwa amagciwane kanye negciwane.

Izimpahla zezemidlalo: Ezinye izinto zezemidlalo ezifana nezicathulo zezemidlalo, izigqoko zezemidlalo, njll. zizosebenzisa ukuhlola amandla okuphefumula ukuze kuqinisekiswe ukusebenza kwazo kokujikeleza komoya.

Ukusetshenziswa kwamandla okuphefumula kwezinye izimboni

Izinto zezingxenye zangaphakathi zezimoto: Thola ukungena komoya kanye nokuphikiswa komoya kwezingxenye zangaphakathi zezimoto (njenge-polyurethane, i-PVC, isikhumba, izindwangu, izindwangu ezingalukiwe, njll.).

Izinto zokwakha: Thola ukungena komoya kwezinto zokwakha (njengetshe, ukhonkolo, njll.) ukuze uhlole amandla azo okuthinta izinga lomoya ngaphakathi kwesakhiwo.

Izinto zokupakisha: Izinto eziningi zokupakisha ezikhethekile (ezifana nokupakishwa okusha, njll.) zidinga ukuba nezinga elithile lokungena komoya ukuze kuqinisekiswe ikhwalithi yokuqukethwe kwephakheji.

Imikhiqizo ye-elekthronikhi: Ezinye izingxenye zemikhiqizo ye-elekthronikhi zidinga umoya omuhle ukuze kuqinisekiswe ukusebenza okuvamile kwempahla kagesi.

Ukuqhathanisa izindlela ezahlukene zokuhlola amandla okuphefumula

Manje, kunamazinga amaningi nezindlela zokuhlola ikhono lokuphefumula kwendwangu. Okulandelayo kukulethela izilinganiso zokuhlola nokuqhathaniswa kokungena komoya kwezindwangu ezisetshenziswa kakhulu ekhaya naphesheya. Lawa mazinga avela emazweni ahlukene noma ezinhlanganweni, ezifana ne-ISO, GB, BS, ASTM, njll. Izindinganiso zomuntu ngamunye zingasebenza ezinhlotsheni ezahlukene zezinto noma imikhiqizo, efana nokungalukiwe, izindwangu, njll. Amazinga ahlukene angase asebenzise izimiso zokuhlola ezihlukene, ezifana njengendlela yokugeleza komoya, indlela yokudlulisa umhwamuko wamanzi, njll. Nakuba izindinganiso eziningi zisebenzisa izimiso zokuhlola ezifanayo, okokusebenza okukhethekile kokuhlola kungase kuhluke kuye ngezidingo zezinga.

1.ISO 9073-15 ISO 9237

Ububanzi bokusebenza: Ifanele ukuhlolwa kokungena komoya kwezinto ezingalukiwe, njengezinto zokuhlunga, izinto zokufaka ezishisayo nezinye izinkambu. Umgomo wokuhlola: Indlela yokugeleza komoya isetshenziselwa ukukala ukugeleza kwegesi ngesampula ukuze kuhlolwe ukusebenza kwekhono lokuphefumula. Imishini yokuhlola: Isihloli sokungena komoya sihlanganisa umthombo womoya, indawo yokuhlola, imitha yokugeleza nezinye izingxenye.

2.I-GB/T 5453 GB/T 24218.15

Ububanzi bohlelo lokusebenza: Isetshenziselwa ukuhlola ukusebenza kwekhono lokuphefumula kwezindwangu, okuhlanganisa izindwangu, izingubo zokugqoka, njll.

Umgomo wokuhlola: Sebenzisa indlela yokugeleza komoya noma indlela yokudlulisa umhwamuko wamanzi ukuze ulinganise izinga legesi noma umhwamuko wamanzi odlula kusampula ukuze uhlole ukusebenza kwekhono lokuphefumula.

Imishini yokuhlola: Izindlela ezihlukene zokuhlola zingadinga okokusebenza okuhlukile. Isibonelo, indlela yokugeleza komoya idinga imishini yokuhlola amandla okuphefumula, futhi indlela yokudlulisa umhwamuko wamanzi idinga imishini yokulawula umswakama, njll.

3. BS 3424-16 BS 6F 100 3.13

Ububanzi bohlelo lokusebenza: Isetshenziselwa ukuhlola ukusebenza kwekhono lokuphefumula kwezindwangu, njengezindwangu, izingubo zokugqoka, njll.

Umgomo wokuhlola: indlela yokugeleza komoya noma indlela yokudlulisa umhwamuko wamanzi isetshenziswa.

Imishini yokuhlola: Amathuluzi ahlukene angase adingeke ngokwezindlela ezihlukene zokuhlola. Isibonelo, indlela yokugeleza komoya idinga imishini yokuhlola amandla okuphefumula, futhi indlela yokudlulisa umhwamuko wamanzi idinga imishini yokulawula umswakama, njll.

4. I-ASTM D737

Ububanzi bokusebenza: Isetshenziselwa kakhulu ukuhlola ukusebenza kwekhono lokuphefumula kwezindwangu.

Umgomo wokuhlola: Indlela yokugeleza komoya isetshenziselwa ukukala ukugeleza kwegesi ngesampula ukuze kuhlolwe ukusebenza kwekhono lokuphefumula.

Imishini yokuhlola: Isihloli sokungena komoya sihlanganisa umthombo womoya, indawo yokuhlola, imitha yokugeleza, njll.

5. I-JIS L1096 Into 8.26 Indlela C

Ububanzi bokusebenza: Isetshenziswa kakhulu embonini yendwangu yaseJapan, ikakhulukazi esetshenziselwa ukuhlola ukusebenza kwekhono lokuphefumula kwezindwangu.

Umgomo wokuhlola: Indlela yokugeleza komoya isetshenziselwa ukukala amandla okuphefumula ezindwangu.

Imishini yokuhlola: Isihloli sokungena komoya sihlanganisa umthombo womoya, indawo yokuhlola, imitha yokugeleza, njll.

Phakathi kwazo, izindlela ezimbili ezijwayelekile, i-ISO 9237 ne-ASTM D737, zisetshenziswa kabanzi. I-GB/T 5453-1997 Leli zinga lisebenza ezinhlobonhlobo zezindwangu zendwangu, okuhlanganisa izindwangu zezimboni, izindwangu ezingalukiwe kanye neminye imikhiqizo yendwangu ephefumulayo. Ngesikhathi sokuhlolwa, izindwangu zokugqoka kanye nezindwangu zezimboni zazihlukaniswa ngobuqili ngokusebenzisa amaconsi ahlukene okucindezela. Ukwehla kokucindezela kwezindwangu zezingubo kwakuyi-100Pa, futhi ukwehla kwengcindezi yezindwangu zezimboni kwakuyi-200Pa. Ku-GB/T5453-1985 "Izindlela Zokuhlola Ikhono Lokuphefumula Kwendwangu", ukungena komoya (kubhekisela kumthamo womoya ogeleza endaweni yeyunithi yendwangu ngesikhathi seyunithi ngaphansi komehluko oshiwo wengcindezi ezinhlangothini zombili zendwangu) isetshenziselwa ukukala ukungena komoya kwendwangu. I-GB /T 5453-1997 evamile ebuyekeziwe isebenzisa ukufinyeleleka komoya (kubhekiselwa esilinganisweni sokugeleza komoya okudlula ngokuqondile kusampula ngaphansi kwendawo yesampula eshiwo, ukwehla kwengcindezi kanye nezimo zesikhathi) ukuveza ukungeneka komoya kwendwangu.

I-ASTM D737 ihlukile kulawa mazinga angenhla mayelana nebanga lesicelo, izinga lokushisa kanye nomswakama, indawo yokuhlolwa, umehluko wengcindezi, njll. Uma kucatshangelwa isimo sangempela sohwebo lwendwangu yokungenisa nokuthekelisa ngaphandle, kuhlelwe ukuthi kusetshenziswe amasampula ahlukene ukuqhathanisa nokuxoxa nge izinga lokushisa elithile kanye nomswakama, indawo yokuhlola, umehluko wengcindezi kanye nezinye izimo ze-ISO 9237 kanye ne-ASTM D737, khetha ukusebenziseka nezimo zokumela, bese usungula amazinga emboni afanelekile ohwebo lokungenisa nokuthumela ngaphandle.

Ukuqhathaniswa kwemiphumela yokuhlolwa

Imiphumela yendwangu yokuphefumula ihlobene eduze nendlela yokuhlola esetshenziswayo. Phakathi kwemiphumela yokuhlolwa etholwe kusetshenziswa izindinganiso ezine zezindlela zokuhlola ezihlukene: ISO 9237, GB/T 5453, ASTM D 737 kanye ne-JIS L 1096: ukungena komoya okuhlolwe ngokwe-GB/T 5453 ne-ISO 9237 kuyafana; ngokusho kwe-GB/T5453 (ISO 9237) ) Ukungena komoya okuhloliwe kuncane kakhulu; amandla okungena komoya ahlolwe ngokwe-JIS L1096 inkulu kakhulu; ukukwazi ukungena komoya okuhlolwe ngokwe-ASTM D737 kuphakathi nendawo. Lapho indawo yokuhlola ihlala ingashintshiwe, ukuvuthwa komoya kuyanda njengoba ukwehla kwengcindezi kukhuphuka, okuhambisana nokwehla kwengcindezi okuphindaphindekayo. Kafushane, kuphela ngokukhetha izindlela zokuhlola ezifanele ezisekelwe kuzici zomkhiqizo lapho ukuphefumula kwezindwangu kungahlolwa ngendlela efanele.

Incazelo enemininingwane yezinyathelo zokuhlola (kuthatha i-GB/T 24218-15 njengesibonelo)

Ukusampula kunqunywa ngokusekelwe kumazinga omkhiqizo noma ukubonisana nezinhlangano ezifanele. Okokusebenza kokuhlola okungahlola ngokuqondile izindwangu ezingalukiwe ezinosayizi omkhulu, okungenani izingxenye ezi-5 zendwangu engalukiwe enosayizi omkhulu zingakhethwa ngokungahleliwe njengamasampula okuhlolwa; ngemishini yokuhlola engakwazi ukuhlola amasampula osayizi abakhulu, isikhunta esisikayo noma isifanekiso singasetshenziswa (Sika okungenani amasampula ama-5 kasayizi ongu-100mmX100 mm).

Beka isampula kusuka endaweni evamile uye endaweni evamile yomoya ethobelana ne-GB/T6529 futhi ulungise umswakama ukuze ulingane.

Bamba unqenqema lwesampula ukuze ugweme ukushintsha isimo semvelo sendawo yokuhlola engalukiwe.

Beka isifanekiso ekhanda lokuhlola bese usilungisa ngesistimu yokubopha ukuze uvimbele ukuhlanekezela kwesifanekiso noma ukuvuza kwegesi emaphethelweni ngesikhathi sokuhlolwa. Uma kunomehluko ekungeneni komoya phakathi kwezinhlangothi zangaphambili nangemuva zesampula, uhlangothi lokuhlola kufanele luphawulwe embikweni wokuhlola. Ngezibonelo ezimboziwe, beka isifanekiso ngohlangothi olunamekwe phansi (lubheke ohlangothini lwengcindezi ephansi) ukuze uvimbele ukuvuza kwegesi emaphethelweni.

Vula iphampu ye-vacuum bese ulungisa izinga lokugeleza komoya kuze kube yilapho umehluko odingekayo ufinyelelwa, okungukuthi, 100Pa, 125Pa noma 200Pa. Kwamanye amathuluzi amasha, inani lokucindezela kokuhlola likhethwa kusengaphambili ngokwedijithali, futhi umehluko wengcindezi kuzo zombili izinhlangothi zembobo yokulinganisa uboniswa ngedijithali kuyunithi yokuhlola ekhethiwe ukuze kube lula ukufunda okuqondile.

Uma kusetshenziswa igeji yokucindezela, linda kuze kube yilapho inani lokucindezela elidingekayo lizinzile bese ufunda inani lokungena komoya ngamalitha ngesentimitha yesikwele isekhondi [L/(cm·s)].

Isikhathi sokuthumela: May-06-2024