Ukuhlolwa kwefenisha yezingane kuhlanganisa izidingo zekhwalithi nokuhlolwa kwekhwalithi yamatafula nezihlalo zezingane, amakhabethe ezingane, imibhede yezingane, osofa bezingane, omatilasi bezingane nezinye ifenisha yezingane.

一 .Ukuhlolwa kokubukekawefenisha yezingane

1. Ukuhlolwa kokubukeka kwezingxenye zokhuni zefenisha yezingane

-Cha ngokusebenzisa imifantu;

-Akukho ukuhlasela kwezinambuzane;

-Ingaphandle kufanele ingabi nokubola, futhi indawo yokubola kancane ngaphakathi akufanele idlule u-20% wendawo yengxenye;

-Ukubukeka nezinto ezisetshenziselwa ukugcina izinto kufanele kungabi namaphakethe e-resin;

-Ububanzi bamafindo angaphandle akufanele budlule u-1/3 wobubanzi bezinto ezibonakalayo, futhi ububanzi akufanele budlule i-12 m (ngaphandle kwezidingo ezikhethekile zokuklama);

- Amalunga afile, izimbobo, amabhantshi, imigudu yeresin, namashaneli ezinsini kufanele kulungiswe (amaphutha anobude obubodwa obukhulu noma ububanzi obungaphansi kuka-5 mm awabalwa). Ngemuva kokulungiswa, inani lamaphutha akufanele lidlule 4 ngaphandle futhi 6 ngaphakathi (design Ngaphandle njengoba kudingwa);

-Okunye ukukhubazeka okuncane okufana nokuqhekeka (ngaphandle kokuqhekeka), imiphetho ebuthuntu, njll., kufanele kulungiswe.

2. Ukuhlolwa kokubukeka kwamaphaneli okwenziwa ifenisha yezingane

-Akufanele kube nezimbali ezomile noma izimbali ezimanzi ekubukeni

-Indawo yezimbali ezomile nezimbali ezimanzi endaweni engaphakathi ayidluli u-5% webhodi lebhodi

-Ebhodini elifanayo, indawo eyodwa ivunyelwe, enendawo engu-3mm ~ 3mm.

Akufanele kube khona imihuzuko esobala ebusweni.

-Akufanele kube khona ukuhlehlisa okusobala ekubukekeni

-Ukubukeka akufanele kube nomehluko wombala osobala

-Ukubukeka kufanele kungabi namagwebu, kuqhekeke futhi kungabi nalutho.

3. Ukuhlolwa kokubukeka kwe-hardware yefenisha yezingane

-Izingxenye ezifakwe ugesi: Ingaphezulu le-coating kufanele lingabi nokugqwala, ama-burrs, nezingezansi ezivulekile; ubuso be-coating kufanele bushelelezi futhi bube flat, futhi akufanele bube namabhamuza, buphuzi, amabala, ukusha, imifantu, imihuzuko, namaqhubu, njll.

-Izingxenye ezifafaziwe: Ukugqoka kufanele kungabi nokuvuza nokugqwala; ukugqoka kufanele kube bushelelezi futhi kulingane, kuhambisane nombala, futhi kungabi nama-pimples, isikhumba esishwabene, upende ondizayo, njll.

-Izingxenye ze-Metal alloy: Akufanele kube nokugqwala, ukuxebuka kwefilimu ye-oxide, imiphetho yokusika, imiphetho ebukhali; ubuso kufanele bube bulungile futhi akufanele kube nemifantu, ama-burrs, amabala amnyama, njll.

-Izingxenye ezishiselwe: Izingxenye ezishiselwe kufanele ziqine, futhi akufanele kube khona ukubola, ukushisela okungamanga, noma ukungena kokushisela; ama-welds kufanele afane, futhi akufanele kube namaphutha njengama-burrs, imiphetho ebukhali, i-spatter, imifantu, njll.

4. Ukuhlolwa kokubukeka kwezingxenye zengilazi zefenisha yezingane

I-periphery eveziwe kufanele ibe nomphetho, futhi ingilazi efakwe ngokuqinile kufanele ihlanzeke futhi ibushelelezi, ingabi nasici njengokuqhekeka, ukuklwebheka, izigaxa, nokubhoboza.

5. Ukuhlolwa kokubukeka kwezingxenye zepulasitiki zefenisha yezingane

Ubuso bezingxenye zepulasitiki kufanele bushelelezi futhi buhlanzeke, ngaphandle kokuqhekeka, imibimbi, amabala, noma umehluko ocacile wemibala.

6. Ukuhlolwa kokubukeka kwamaphakheji wefenisha yezingane

Amaphethini we-symmetrical ahlanganisiwe wezindwangu ezimboziwe kufanele aphelele; izinkomba zenqwaba zezindwangu ze-velvet engxenyeni efanayo kufanele zihambisane; akufanele kube khona umehluko wombala osobala. Indwangu emboziwe akufanele ibe nemihuzuko, amabala ombala, amabala kawoyela, i-fluffing, noma i-pilling.

Ingaphezulu lekhava elithambile kufanele libe:

1) isicaba, igcwele, futhi iqine ngokulinganayo, ngaphandle kwemibimbi esobala;

2) imibimbi elinganayo kanye nezobuchwepheshe okufanele ilinganiswe kahle futhi ihlelwe kahle.

Imicu efakwe endaweni ethambile kufanele:

1) kube bushelelezi futhi iqonde;

2) ibe yi-symmetrical emakhoneni ayindilinga;

3) ayinazo izintambo ezintantayo ezisobala, imithungo esobala eyeqiwe noma imiphetho yentambo eveziwe.

Izinzipho zebhamuza eziveziwe:

1) Ukuhlelwa kufanele kucoceke futhi isikhala siyalingana;

2) Akufanele kube nezinzipho ezisobala eziyisicaba noma ezixebukayo.

7. Ukuhlolwa kokubaza kwefenisha yezingane

Izindawo ezingaxhumene zezingxenye zephaneli yokwenziwa kufanele zivalwe ngomphetho noma zipendwe. Amabhodi noma izingxenye akufanele zibe nama-burrs, imiphetho noma amakhona lapho zihlangana khona nomzimba womuntu noma lapho kugcinwa khona izinto. Ubuso bepuleti noma ingxenye kufanele bushelelezi, futhi ama-chamfers, ama-fillets, nemigqa eyindilinga kufanele ihambisane. Akufanele kube khona ukukhishwa kwe-degumming, ukubhibhidla noma ukuqhekeka ku-veneer, ukuvala onqenqemeni nokusonga. I-veneer kufanele iqine futhi ibushelelezi, futhi akufanele kube khona ukungena kweglue okusobala, amakhona epulaki, kanye nokuhlangana phakathi kwezingxenye nezingxenye akufanele kuphulwe. Inhlanganisela yezingxenye kufanele iqine futhi iqine. Ukufakwa kwezinsiza ezihlukahlukene nezixhumi akufanele kufake izingcezu ezingekho noma izipikili ezingekho (ngaphandle kwezimbobo ezigodliwe nezimbobo ozikhethela).Ukufakwa kwezisekeli ezihlukahlukene kufanele kube okuqinile, okubushelelezi, okuqondile futhi okuqinile, futhi amalunga kufanele angabi nemifantu noma axege. .

Izingxenye zokuvula nokuvala kufanele ziguquguquke ukuze zisetshenziswe ngemva kokufakwa. Iphethini eqoshiwe kufanele ifane, icace, futhi ichazwe kahle, futhi izingxenye ezilinganayo kufanele zilingane. Akufanele kube khona amakhona ashodayo kuma-convex nama-digs amakhulu, amabhuloho, imiphetho, nama-arcs. Iphansi lefosholo kufanele libe isicaba, futhi akufanele kube nezimpawu zesando noma ama-burrs kunoma iyiphi ingxenye. Inani lamaphutha entweni ngayinye akufanele lidlule 4. Umumo womugqa wokhuni oluphendukile kufanele uhambisane, izinyathelo eziqondile kanye ne-convex kufanele zilingane, izingxenye ezilinganayo kufanele zilingane, imigqa ephendukayo kufanele icace, futhi akufanele kube khona. izinhlanga, izimpawu zommese, noma izimpawu zesihlabathi endaweni ecutshunguliwe. Inani lezinkinga entweni ngayinye akufanele lidlule 4. Izingidi zefenisha kufanele zikhiyelwe endaweni futhi zivuleke kalula. Ama-caster kufanele aguquguquke ukuze ajikeleze noma ashelele.

8. Ukuhlolwa kokubukeka kwefilimu yepende efenisha yezingane

Izingxenye ezinombala ofanayo kufanele zibe nemithunzi efanayo. Akufanele kube nokufiphala noma ukuguquguquka kombala. Ukumboza akufanele kushwabene, kunamathele noma kuvuze. Ukugqoka kufanele kube bushelelezi, kucace, ngaphandle kwezinhlayiya ezisobala noma ukuvuvukala komphetho; akumele kube namamaki okucubungula asobala, imihuzuko, imifantu, inkungu, imiphetho emhlophe, amachashaza amhlophe, amabhamuza, amhlophe anamafutha, ama-sagging, izimbobo ezinciphayo, ama-bristle, njll. Impushana enqwabelene kanye nemfucumfucu. Inani lamaphutha entweni ngayinye akufanele lidlule ku-4.

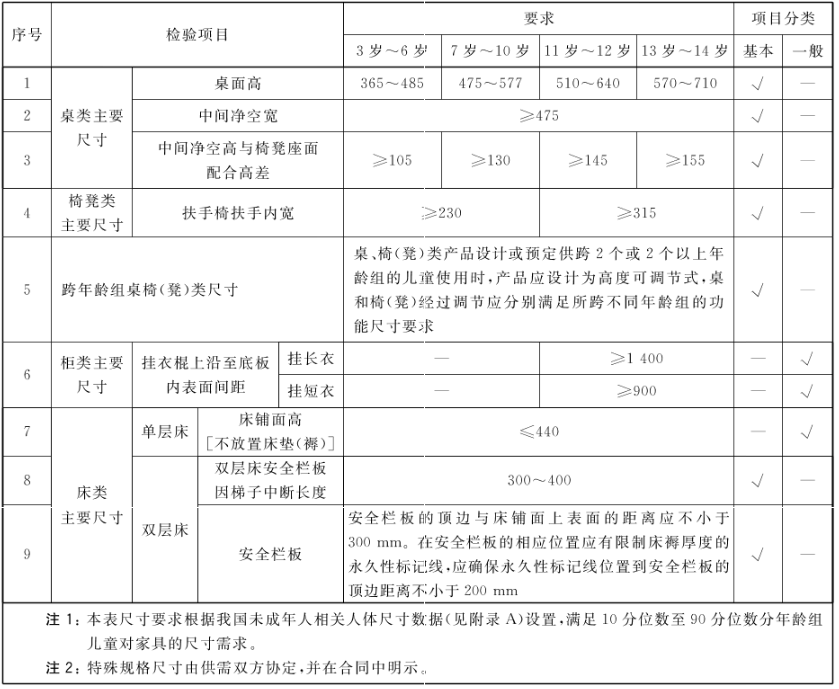

二 Ifenisha yezinganeukuhlolwa kosayizi

Izidingo zosayizi oyinhloko wefenisha yezingane:

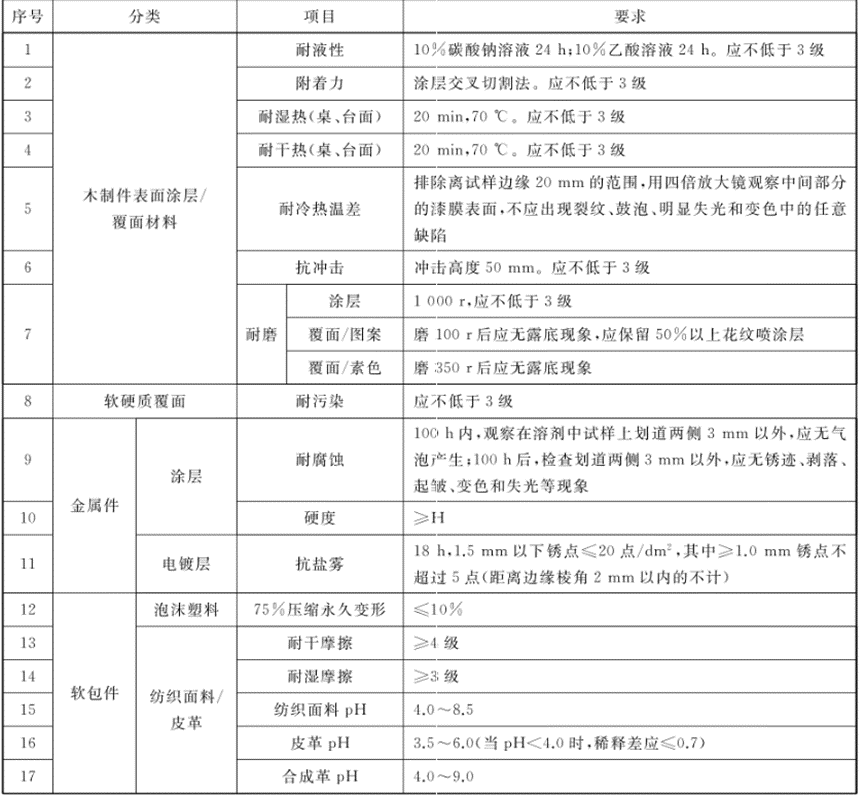

三 Ukuhlolwa kokusebenza komzimba namakhemikhaliwefenisha yezingane

四 Ifenisha yezinganeukuhlolwa kwesakhiwo

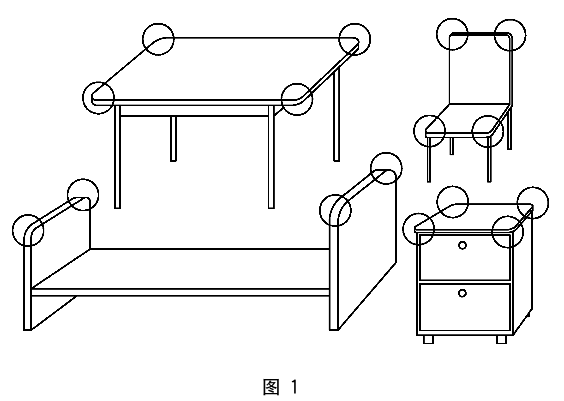

1.Ikhona langaphandle

Amakhona angaphandle ayingozi efenisha yezingane afinyeleleka ngaphansi kokusetshenziswa okujwayelekile (bheka indawo eyindilinga kuMfanekiso 1) kufanele abe yindilinga, ibe ne-radius engekho ngaphansi kuka-10 mm, noma ubude be-arc obuyindilinga obungekho ngaphansi kuka-15 mm. imiyalelo yomkhiqizo isho ngokucacile ukuthi umkhiqizo udinga ukubekwa odongeni futhi uxhunywe odongeni, ikhoneni elingaphandle lomkhiqizo ohlangothini lodonga akudingeki ukuba liyindilinga.

2. Imiphetho ebukhali efinyeleleka kalula

Amaphethelo ezinto ezifinyeleleka eziqinile emkhiqizweni ahlolwa njengeziphetho ezicijile futhi akufanele abe imiphetho ebukhali eyingozi.Ngaphandle kokusetshenziswa kwamathuluzi akhethekile, imicu yebhawodi emkhiqizweni iveza unqenqema olufinyeleleka kalula ngokuphendula inkinobho, futhi lolu nqenqema kufanele uphumelele ukuhlolwa okubukhali.

3. Amaphuzu abukhali afinyelelekayo ayingozi

Amaphuzu ezinto eziqinile ezifinyelelekayo emkhiqizweni ahlolwa njengamaphuzu abukhali futhi akufanele abe amaphuzu abukhali ayingozi.

4. Ama-protrusions ayingozi

Umkhiqizo akufanele ube nama-protrusions ayingozi. Uma kukhona ama-protrusions ayingozi, kufanele avikelwe ngezindlela ezifanele. Isibonelo, goba ukuphela noma wengeze isivikelo noma ikhava ukuze ukhulise ngempumelelo indawo engase ihlangane nesikhumba.

5. Izimbobo, izikhala kanye nokuvuleka kufanele kuhlangabezane nezidingo ezilandelayo:

Ngezimbobo, izimbobo kanye nezikhala ezintweni eziqinile zomkhiqizo ezinokujula okudlula i-10 mm, ububanzi noma igebe lizoba ngaphansi kwama-7 m noma likhulu noma lilingane no-12 mm ngokusho kokuhlolwa; ukuvuleka kwazo zonke izingxenye ze-tubular ezifinyelelekayo emkhiqizweni kuzovalwa ngesembozo sokuvala noma i-cap; Yenza ukuhlolwa okuqinile ezingxenyeni zokuzivikela ukuze uqinisekise ukuthi aziwi.

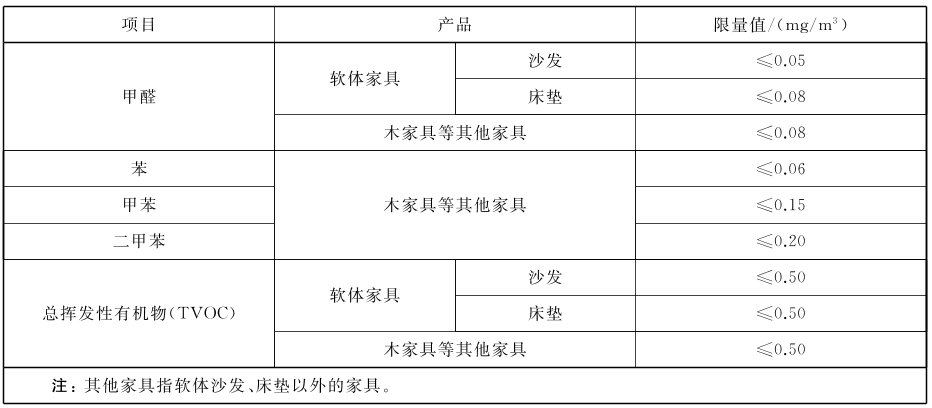

五Ifenisha yezingane i-formaldehyde, i-benzene, i-toluene, i-xylene TVOC emission kanye nokunye ukuhlolwa komkhawulo wezinto

Izidingo zokukhishwa kwe-Formaldehyde, benzene, toluene nexylene TVOC zefenisha yezingane:

Izidingo ezilinganiselwe zezinye izinto zefenisha yezingane:

六 Ukuhlolwa kokusebenza komshiniwefenisha yezingane

Ngemuva kokuthi ukuhlolwa kokusebenza kwemishini kwenziwa ngokuhambisana nemithethonqubo, lezi zidingo ezilandelayo kufanele zihlangabezane nazo: azikho izingxenye noma izingxenye eziphukile, eziphukile noma eziwile; akukho ukuxega, ukuguga noma ukuguqulwa okuthinta umsebenzi wokusetshenziswa; ezinye izingxenye okufanele ziqine kufanele zicindezelwe ngesandla, futhi akukho ukuxega unomphela , njengokukhipha insangu; izingxenye ezinyakazayo (iminyango, amadrowa, njll.) zingavulwa futhi zivalwe kalula; i-hardware ayinakho ukuguqulwa okusobala, ukulimala noma ukuwa; indwangu yefenisha ye-upholstered ayinayo umonakalo, akukho ziphethu eziphukile, ama-seams awaxhunyiwe ku-line, futhi izinto zokupakisha azonakaliswa noma zisuswe; Ngesikhathi sokuhlolwa kokuzinza, umkhiqizo awuzange uphele.

Isikhathi sokuthumela: Dec-20-2023