Ikhadibhodi likathayela liyikhathoni elenziwe ngokusika, ukusika, ukubethela noma ukunamathisela.

Amabhokisi kathayela ayimikhiqizo yokupakisha esetshenziswa kakhulu, futhi ukusetshenziswa kwawo bekulokhu kungokokuqala phakathi kwemikhiqizo ehlukahlukene yokupakisha. Kubandakanya amabhokisi kathayela epulasitiki ye-calcium.

Iminyaka engaphezu kwengxenye yekhulu, amabhokisi kathayela ashintshile kancane kancane amabhokisi okhuni nezinye iziqukathi zokupakisha zokuthutha ngokusebenza kwawo okuphakeme nokusebenza kahle kokucubungula, abe amandla amakhulu okupakisha ezokuthutha.

Ngaphezu kokuvikela izimpahla kanye nokwenza lula ukugcinwa nezokuthutha, kuphinde kube neqhaza ekuhlobiseni nasekukhuthazeni izimpahla.

Amabhokisi kathayela ayimikhiqizo eluhlaza futhi evumelana nemvelo, alungele ukuvikelwa kwemvelo futhi alungele ukulayishwa, ukuthulula nokuhamba.

Ibhokisi likathayela liwumkhiqizo ojwayelekile wokupakishwa kwamaphepha ongehlukaniseki ezimpilweni zethu nasekukhiqizeni. Ukuhlola izinkomba ezihlukahlukene zamandla kuyisixhumanisi esibaluleke kakhulu ekukhiqizeni futhi kubaluleke kakhulu ekuqinisekiseni ikhwalithi nokusebenza komkhiqizo. Ukuze kukhiqizwe imikhiqizo yamakhathoni afanelekayo, amabhokisi kathayela kufanele ahlolwe ukuze inqubo yokukhiqiza amabhokisi kathayela ilawulwe ngempumelelo.

01.Ikhwalithi yokubukeka

Amabhokisi afanelekayo adinga amaphethini aphrintiwe acacile nokubhala, ngaphandle kwemigqa ephukile noma imigqa engekho; umbala wephethini uyavumelana, ugqamile futhi ugqamile, futhi iphutha lesikhundla sokuphrinta lincane. Iphutha lamabhokisi amakhulu lingaphakathi kuka-7mm, futhi iphutha lamabhokisi amancane lingaphakathi kuka-4mm. Izinga eliphezulu kufanele libe liphelele, ngaphandle kokulimala noma amabala, akufanele kube nezimbobo eduze kwebhokisi, futhi akufanele kube nezikhala lapho izivalo zivaliwe. Ngaphezu kwalokho, amajoyinti ekhabhinethi nawo adingeka ukuthi afane, abe nemiphetho ehlanzekile futhi awekho amakhona agqagqene.

02.Okuqukethwe umswakama

Okubizwa ngokuthi umswakamo ubhekisela kumswakama osephepheni likathayela noma amakhadibhodi, ovezwa njengephesenti. Okuqukethwe umswakama kunomthelela omkhulu emandleni ebhokisi lebhokisi. Ingenye yezinto ezintathu ezinkulu zokuhlola ukukhubazeka kwebhokisi. Iphepha lesisekelo elifakwe uthayela linokumelana okuthile nokucindezelwa, ukumelana nokuqina, ukumelana nokubhoboza kanye nokumelana nokugoqa. Uma umswakamo uphezulu kakhulu, iphepha lizobonakala lithambile, libe nokuqina okungekuhle, futhi libe nekhwalithi ephansi ye-corrugating ne-bonding. Uma umswakamo uphansi kakhulu, iphepha lizoba brittle kakhulu, lijwayele ukuqhekeka phakathi nokonakala, futhi lizoba nokungagoqeki kahle. Uma umehluko womswakamo phakathi kwephepha likathayela nephepha lebhokisi mkhulu kakhulu, ikhadibhodi likathayela elicutshungulwa umshini wohlangothi olulodwa lizogoqeka kalula, futhi amabhamuza kanye ne-degumming kuyokwenzeka lapho i-laminating. Uma ibhokisi elibunjiwe lithatha umswakama ngesikhathi sokugcina, amandla ebhokisi azoncishiswa kakhulu, athinte ukusetshenziswa kwawo.

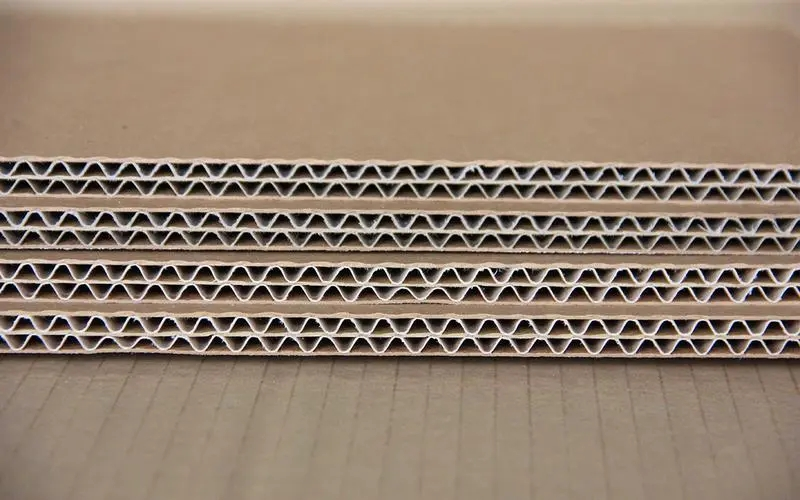

03. Ukujiya kwekhadibhodi

Kunezizathu eziningi ezithinta ukushuba kwekhadibhodi. Uma ubukhulu bekhadibhodi likathayela buncane, amandla ayo okucindezela onqenqemeni, amandla okubhoboza namandla acindezelayo azoncishiswa ngokufanele. Ikhadibhodi likathayela linezinhlobo ezahlukene zomtshingo nogqinsi oluhlukene. Amalabhorethri ngokuvamile asebenzisa amamitha okujiya kathayela ukuze athole ukujiya kwekhadibhodi.

04.Isisindo sebhokisi

Ukulinganisa isisindo samakhathoni nakho kuwumsebenzi obalulekile ezinkampanini zamabhokisi. Izinkampani zamakhathoni zidinga ukukala izisindo zebhokisi ngesikhathi sezimemezelo zokuthumela ngaphandle nalapho zibala okukhiphayo. Ngaphezu kwalokho, ngezinye izikhathi amakhasimende azosebenzisa izisindo zebhokisi njengenye yezindinganiso zokuhlola izinto zebhokisi. eyodwa.

05. Amandla okucindezela onqenqemeni

Inani lokucindezela isampula lobubanzi obuthile elingamelana nalo ngobude beyunithi libizwa ngokuthi amandla okucindezela onqenqemeni. Amandla okucindezela onqenqemeni lwebhokisi likathayela asho ikhono lokumelana nengcindezi ehambisana nendawo kathayela. Amandla okuchotshozwa kwendandatho ephepha lesisekelo namandla okubopha ekhadibhodi anquma amandla okuchotshozwa onqenqemeni kwekhadibhodi ngokwezinga elikhulu. Imiphumela ichazwa njengamanani aphansi.

06. Amandla acindezelayo

Amandla acindezelayo ebhokisi likathayela abhekisela kumthwalo omkhulu kanye nokuguqulwa okungamelana nawo kuze kube yilapho ibhokisi lonakaliswa lapho umshini wokuhlola ingcindezi usebenzisa ingcindezi eguquguqukayo ngokulinganayo. Phakathi nayo yonke inqubo yokucindezela i-carton, amakhona amane agcizelelwe ngokuyinhloko, ebala cishe izingxenye ezimbili kwezintathu zamandla aphelele. Ngakho-ke, phakathi nenqubo yokukhiqiza, kufanele sizame ukunciphisa umonakalo kuma-corrugations azungeze amakhona amane ebhokisi. Amandla okucindezela amabhokisi ahlukaniswe abe inani elisebenzayo kanye nenani lokugcina. Ikhwalithi engcono yebhokisi, iphakamisa inani elisebenzayo lamandla okucindezela, kanye nokuchezuka okuncane phakathi kwevelu esebenzayo kanye nevelu yokugcina.

07. Amandla okunamathela

Izinga lokunamathela phakathi kwephepha eliphezulu lekhadibhodi elinothayela, iphepha loqweqwe lwawo, iphepha eliwumgogodla kanye nephepha likathayela, namandla okuxebula angakwazi ukumelana nawo phakathi nobude beyunithi ethile, kubizwa ngokuthi amandla okunamathela ekhadibhodi likathayela, elimelela amandla amakhadibhodi kathayela. ukuqina. Ikhwalithi, ifomula, izinto zokusebenza, inqubo yokusebenza nezinye izici ze-adhesive zinquma amandla okunamathela ekhadibhodi, futhi amandla okunamathela ekhadibhodi athinta kakhulu ukumelana nokucindezela nokuqina kwebhokisi. Amandla aqhumayo namandla okubhoboza.

08.Ukugoqa ukubekezela

Njengesitsha sokupakisha, isivalo sekhathoni sidinga ukuvulwa njalo, okudinga ukuthi ikhadibhodi libe nokumelana okuthile nokugoqa.

Izakhiwo ze-slurry ze-boxboard ne-whiteboard paper, okuqukethwe komswakama, ukuqina, ubude be-fiber nokushesha kokubopha kwephepha lesisekelo, kanye nesikhathi sokugcina kanye nezinga lokushisa lephepha lesisekelo, kunquma ngokwezinga elikhulu ukumelana nokugoqa kwephepha lesisekelo. . Lokhu kunquma ukumelana nokugoqa kwebhokisi.

09. Ukusebenza okunamandla kwebhokisi

Ngokupakishwa kwezinto ezithile ezinjengama-ceramics, imikhiqizo yengilazi, amathuluzi kagesi, njll., ukusebenza kwe-cushion yamabhokisi ezimpahla kumele nakho kuhlolwe, okungukuthi, izivivinyo ezifana nokulingiswa kokuhamba, ukulayisha nokuthulula, ukudlidliza, kanye kwenziwa amaconsi ukuze kuhlolwe ukusebenza kwamabhokisi.

Isigaba A esingafanelekile: Ibhokisi alikwazi ukuhlangabezana nomsebenzi wokuvikela noma wokumaka okuqukethwe.

(1) Imithungo iyahlukana.

(2) Ubukhulu bungaphezu kobubanzi obuvumelekile bephutha.

(3) Ikhwalithi ingaphansi kwenani elincane elishiwo.

(4) Umugqa wokuhlehlisa uphukile noma ingaphezulu lephepha linqanyuliwe.

(5) Ingaphezulu lidabukile, libhobokile, linezimbobo, noma izicucu zekhava azifani futhi zinezicucu zekhadibhodi ezinamathele kuzo.

(6) Amaphutha okuphrinta, ukuphrinta okungaphelele noma amaphutha ombala namaphethini.

(7) Ukungcola okubangelwa izinto ezingaphandle.

Isigaba B asifanelekile: Ikhathoni alisebenzi ngokugcwele noma linezinkinga.

(1) Ama-seams awaboshiwe ngokuphelele, amalunga e-tape awaphelele noma amalunga awabethelwanga ngokwanele.

(2) Izikhala zisikwa emaphethelweni ezinhlangothi zebhokisi.

(3) Izingcezu zekhava azikwazi ukudojwa, futhi igebe likhulu kuno-3mm.

(4) Umswakama wekhadibhodi ungaphezu kuka-20% noma ungaphansi kuka-5%.

(5) Ikhathoni ligotshwe ezindaweni ezingaqondile.

(6) Ukuphrinta kwebhokisi akuphelele noma ihluzo nombhalo kufiphalisiwe.

(7) Ibhokisi alizithathi izinyathelo zokunqanda ukushelela njengoba kudingeka.

Isigaba C asifanelekile: Ukubukeka kwebhokisi kubi, kodwa umsebenzi walo awuthinteki.

(1) Ukusika i-slotting noma i-carton die cut kulukhuni.

(2) Ingaphezulu lekhadibhodi linokungalingani okufana ne-washboard, okuthinta ikhwalithi yezithombe eziphrintiwe nombhalo.

(3) Kukhona amabala okungcola endaweni yebhokisi.

(4) Ukuklwebheka okungashoni noma amamaki akhuhliwe.

Isikhathi sokuthumela: Mar-27-2024