Kunezinhlobo eziningi zefenisha, njengefenisha yokhuni oluqinile, ifenisha yensimbi eyenziwe, ifenisha yamaphaneli, nokunye. Izinto eziningi zefenisha zidinga abathengi ukuthi bazihlanganise ngokwabo ngemva kokuthenga. Ngakho-ke, lapho abahloli bedinga ukuhlola ifenisha ehlanganisiwe, badinga ukuhlanganisa ifenisha esizeni. Yiziphi izinyathelo zemishini yokuqaqa nokuhlanganisa ifenisha, ukuthi isetshenziswa kanjani esizeni, futhi yiziphi izinyathelo zokuphepha.

1.Inani lokuhlolwa komhlangano wendawo

1) Umhloli kufanele ahlanganise ngokuzimela okungenani isethi eyodwa yemikhiqizo ngokuya ngemanuwali yokuhlanganisa. Uma usayizi womkhiqizo mkhulu kakhulu futhi udinga usizo lwabasebenzi basefekthri, kuyadingeka ukuqinisekisa ukuthi ukuxhuma kanye nezingxenye ezifanayo zifakwe futhi ziqhutshwa ngumhloli ngokwazo.

2) Ukuhlanganiswa kweminye imikhiqizo kungaqedwa ngabasebenzi basefekthri, kodwa kudinga ukuqedwa ngaphansi kokuqondisa okugcwele endaweni yomhloli. Kubalulekile ukuhlola yonke inqubo yokuhlanganisa umkhiqizo, kunokugxila kuphela kumphumela wokugcina wokuhlanganisa. Ngakho-ke, ngesikhathi senqubo yemishini, umhloli akakwazi ukushiya indawo yomhlangano, futhi ubuningi bemishini buncike ezidingweni zokuhlola (WI).

2.Ezindaweni zomhlangano izinyathelo kanye nezinyathelo zokuphepha

1) Izinto zokusebenza endaweni kufanele zilandele ngokuqinile imiyalelo yomhlangano enikezwe umkhiqizo. Phakathi nenqubo yokuhlanganisa, hlola ukuthi izinyathelo zemiyalelo yomhlangano zilungile yini, ukuthi ingxenye ngayinye iyahlangabezana yini nezidingo zobuchwepheshe, ukuthi ilingana ngokuqinile, ukuthi indawo yembobo ilungile yini, ingabe umkhiqizo uqinile, nokuthi amathuluzi angaphandle ayadingeka yini (ngokuvamile akudingekile. kuvunyelwe, izidingo ezithile zincike emiyalweni)

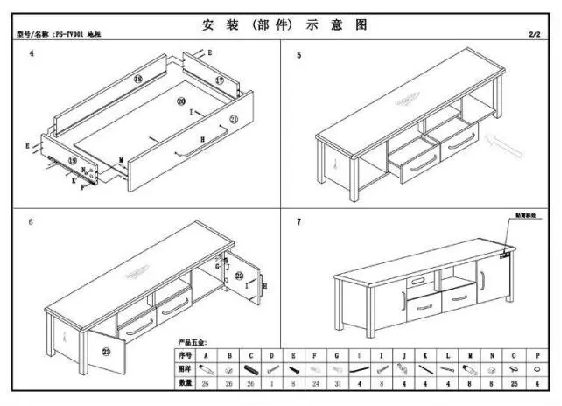

2) Ngaphambi kokuhlanganisa, kubalulekile ukukhomba inombolo yezingcezu zomkhiqizo, uvule ibhokisi lekhadibhodi lokupakisha, ubeke iphakheji ye-hardware endaweni ehlukile futhi uyibale ukuze ugweme ukulahlekelwa noma ukuxubana nezesekeli ezivela kweminye imikhiqizo.

3)Okokuqala, hlola ukuthi inombolo nosayizi wezingxenye kuyahambisana yini nenani elikhonjiswe encwadini. Ngesikhathi sokuhlanganisa, qaphela ukuthi ungashintshi izingxenye ezingafaneleki.

4) Funda ngokucophelela imanuwali yomhlangano, okokuqala uhlukanise izingxenye eziyinhloko ngokulandelana, futhi uvakashele amabhodi ngokuhlukana ukuze ufanise ukufakwa. Kungcono ukuthatha izithombe zalawa mabhodi ngokufanayo.

5) Lungiselela amathuluzi okufaka anjengama-screwdrivers, ama-wrenches, njll., futhi ulandele ngokuqinile izinyathelo zomhlangano kubhukwana lokuhlanganiswa komkhiqizo phakathi nenqubo yokuhlanganisa. Abahloli badinga ukunaka okukhethekile: abasebenzi basefekthri bavame ukuthembela kokuhlangenwe nakho ngesikhathi sokuhlanganiswa futhi bayehluleka ukulandela ngokugcwele izinyathelo ezikubhukwana lemishini. Lo mkhuba awukwazi ukuqinisekisa ukuthi imanuwali yesisetshenziswa inengqondo futhi iphelele. Uma lesi simo sitholakala, kufanele simiswe/silungiswe ngokushesha. Kungcono ukufaka iyunithi eyodwa ngesikhathi, hhayi amayunithi amaningi ngesikhathi esisodwa, ukuze ugweme ukugadwa okunganele.

6) Ngokuvamile, inqubo yokuhlanganisa imikhiqizo eminingi ingahlukaniswa ngezigaba ezine:

Isinyathelo sokuqala ukwakha uhlaka lwamathambo omkhiqizo. Phakathi nale nqubo, kufanele kuqashelwe ukuthi izimbobo zokuxhuma ze-skeleton zilungile, kungakhathaliseki ukuthi ukufakwa kwama-bolts nezinye izinsimbi zibushelelezi, kungakhathaliseki ukuthi izixhumi zivaliwe, nokuthi izikhala ze-skeleton zifana futhi zihambisana.

Isinyathelo sesibili ukufaka izingxenye ezimisiwe eziqinisa isakhiwo ku-skeleton. Phakathi nale nqubo, ukunakwa kufanele kukhokhwe ezesekeli ze-hardware, ikakhulukazi izikulufa, okungafanele ziphuthelwe. Zonke izingxenye nezinsimbi kufanele zibekwe kuhlaka, futhi izimbobo zokuxhuma kufanele zihlolwe ukufaneleka. Kubalulekile ukuqaphela ukuthi ukungahambi kahle kwembobo yesikulufa kuvame ukwenzeka phakathi nale nqubo.

Isinyathelo sesithathu ukufaka izisetshenziswa eziqondisayo noma ukuhinge izingxenye ezihambayo ezixhumene ezindaweni ezihambisanayo. Kubalulekile ukuqaphela ukuthi izingxenye zefenisha zingahlakazwa futhi zihlanganiswe izikhathi eziningi ngaphandle kwezinkinga zokulimala. Kule nqubo, kufanele kuqashelwe ukuthi lezi zesekeli zinezimbobo zesikulufa ezixekethile noma izingxenye ezilimele ngemva kokuxhumeka okukodwa.

Ingxenye yesine ukufaka izingxenye ezincane noma zokuhlobisa noma izesekeli. Phakathi nale nqubo, kufanele kuqashelwe ukuthi ubude besikulufa buyahlangabezana yini nezidingo, noma ngabe izesekeli zokuhlobisa zingaqiniswa ngokuqinile, noma ngabe indawo yembobo ifanelekile yini lapho ukhiya isikulufu, nokuthi umkhiqizo akufanele yini ukuklwejwa noma izesekeli akufanele. khululeka.

Imibuzo ejwayelekile ukubuzwa

1. Ukuntuleka kwezingxenye zomkhiqizo, ikakhulukazi izesekeli ze-hardware emaphaketheni amancane

2. Indawo yembobo ayihlangabezani nezidingo, ikakhulukazi okuhlanganisa indawo engalungile yembobo yokuxhumana, imbobo encane, imbobo engashoni kakhulu noma ejulile kakhulu, ukuchezuka kwesiqondiso, njll.

3. Izimbobo ze-accessory ebhodini zigcwele upende, futhi i-hardware ayikwazi ukufakwa kahle

4. Izesekeli zezingxenyekazi zekhompuyutha azikwazi ukukhiywa ngokuqinile, futhi umkhiqizo awuvikelekile

5. Uma ukhiya izesekeli zehadiwe, izakhi zingase ziwohloke, ziqhekeke, noma zilimale

6. Izingxenye ezihambayo ezisebenzayo azikwazi ukusunduzwa noma ukudonsa kahle

7. Izixhumi ezilimele kanye namabala okugqwala ebusweni bezesekeli zehadiwe

8. Izikhala ezeqile noma ezingalingani phakathi kwezingxenye ngesikhathi sokuhlanganisa

Izimfuneko zekhwalithifuthiizindlela zokuhlolaokwemikhiqizo

1. Indlela yokuhlola

Ukulinganisa ithuluzi, ukuhlola okubukwayo, ukuthinta ngesandla, nokuhlolwa kwemikhiqizo ngokuya ngezidingo zobuchwepheshe zokuhlanganiswa komkhiqizo kanye nobukhulu bomdwebo kanye nokwakheka

2. Ibanga lokutholwa

Kufanele ibe ngaphansi kokukhanya kwemvelo noma cishe ukukhanya kwemvelo (isb. 40W isibani sefluorescent), enobubanzi obubonakalayo obungu-700-1000mm.

3. Ukugxila ekuhloleni ukubukeka

1) I-welding, riveting, mortise kanye namajoyinti e-tenon asetshenziselwa ukulungisa izingxenye akufanele akhululeke.

2) Izikulufu noxhumo lwezingxenyekazi zekhompuyutha akumele zikhululeke

3) Ingaphezulu lezesekeli ze-hardware alinamihuzuko, ungqimba lwe-plating (olunamathelayo) luqinile, futhi akukho ukuxebuka noma ukugqwala.

4) Izingxenye zokuthwala imithwalo kanye nezingxenye ezihambayo akumele zibe nemifantu, amafindo, izimbobo zezinambuzane, noma okunye ukukhubazeka.

I-5) Izingxenye ezihambayo kufanele zixhumeke ngokuqinile nangokuthembekile, zingawi zodwa, futhi kufanele ziguquguquke futhi kube lula ukuzisebenzisa.

6) Ukufakwa kwensimbi akufanele kube nemifantu noma izibazi

7) Akufanele kube khona ukubola, ukushisela okubonakalayo, noma ukungena kwe-welding endaweni yokushisela

8) Izingxenye ezishiselwe kufanele zingabi nama-pores, ama-weld nodules, kanye ne-spatter

I-9) Izingxenye eziboshwe kufanele zikhishwe ngokushelela ngaphandle kwezimpawu zesando

10) Ukugqoka akufanele kube nokusha, amagwebu, izimbobo, imifantu, ama-burrs, nemihuzuko.

11) Ukumbozwa kwezingxenye zensimbi akufanele kube nezansi esobala, ukungalingani, ukuwohloka okusobala, izigaxa, imibimbi, noma upende ondizayo.

12) Akukho mihuzuko noma imihuzuko ebusweni bomkhiqizo oqediwe

I-13) Isakhiwo sonke somkhiqizo siqinile, silinganisela phansi, futhi akukho ukuxega ezingxenyeni lapho kunyakaziswa. Amalunga aqinile futhi awekho amagebe asobala

14) Amalensi kanye neminyango yekhabethe lengilazi ihlanzekile ngaphandle kwezimpawu zokunamathela, futhi isibopho noma amalunga aqinile futhi aqinile.

15) Izesekeli zezingxenyekazi zekhompuyutha ezivame ukuvulwa, njengamahinge, okuhoxiswayo, amaslayidi ekhabetheni, njll., zidinga ukuvulwa nokuvala okuvumelana nezimo.

I-16) Izingxenye zokhuni eziqinile azinazo izimpawu zokubola, izimbobo zezinambuzane, ukuphuka, njll., futhi isiqondiso sombala nokusanhlamvu kwezinkuni kuyahambisana. Umswakamo uhlangabezana nezidingo

17) Ukufakwa kwezingxenye zokhuni akufanele kube nemibimbi noma ukuvuza kwepende: ukumbozwa noma ukunamathela kwezingxenye zensimbi akufanele kube nokuxebuka, ukufekethisa, noma ukuvuza kopende.

18) Ukugqoka ezingxenyeni zokhuni kufanele kube flat futhi bushelelezi, ngaphandle kwemihuzuko, amabala amhlophe, amabhamuza, ama-sagging, kanye nokwehluka kombala okusobala.

19) Izingxenye zephaneli azinawo umgodi, okuxekethile, izinambuzane, ukuqhekeka, ukuchotshozwa, ukuklwejwa, ukubethelwa, ukubhobozwa, nezinye izenzakalo.

20) Umbala ongaphezulu kufanele uhambisane, kungakhathaliseki ukuthi uqhathanisa ucezu olulodwa ezindaweni ezihlukene noma uqhathanisa lonke uhlelo, umbala kufanele uhambisane

21) Awekho amamaki amathuluzi asobala ebusweni, njengezimpawu zommese, izimpawu zokudonsa, ukuhlukana, ukuqhekeka, ukumnyama kwesihlabathi, nokucwila.

22) Ihinge akufanele igotshwe noma iphakanyiswe ngokweqile, futhi ayivunyelwe ukulungisa umnyango ngokugoba ihinge ukuze igcine ukucaba kwayo.

I-23) Ingilazi nezibuko kufanele zifakwe ngaphandle kokuthuthumela noma ukukhulula

I-24) Umkhiqizo awunawo ama-debris, ama-protrusions abukhali, ama-burrs, ama-glue marks, amnyama ashile, noma ukufafaza ngokweqile.

25) Usayizi ophelele womkhiqizo oqediwe uhlangabezana nezidingo zomdwebo, futhi ubukhulu bangaphandle bungaphakathi kwebanga elivumelekile lokubekezelela usayizi.

Izesekeli zehadiwe ezivamileyokudiliza nokuhlanganisa ifenisha

Izesekeli ze-Hardware ngokuvamile zisetshenziselwa ukulungisa nokuxhuma isakhiwo lapho kuqaqa ifenisha. Izixhumi ezivamile kwifenisha zihlanganisa amahinge, izixhumi (eccentric noma unomphela), amaslayidi ekhabetheni, amaslayidi eminyango eshelelayo, izibambo, izingidi, izikhonkwane zokukhiya, izinkomishi zokudonsa umnyango, izisekelo zokuhlukanisa, izinti zezingubo ezilengayo, amapulangwe, imilenze, amabhawodi, izikulufu zokhuni, izintambo zokhuni. , izinzipho eziyindilinga, njll.

1. Ihinji

Amahinge yizakhiwo eziyinhloko ezixhuma izingxenye ezimbili ezihambayo, ikakhulukazi ezisetshenziselwa ukuvula nokuvala iminyango yekhabhinethi, ihlukaniswe yaba amahinge avuliwe kanye namahinge afihliwe.

1) I-Ming hinge

Amahinge ngokuvamile amahinge kuphela, futhi lapho efakiwe, ingxenye yephinikhodi ye-hinge ibonakala ebusweni befenisha. Amahinge angasetshenziselwa iminyango eyakhelwe ngaphakathi kanye neminyango egoqayo.

2) Ihinge efihliwe

Ihinge efihliwe izungeza ngentonga yokuxhuma futhi ifihlwe ngaphakathi kwefenisha ngesikhathi sokufakwa ngaphandle kokuvuza.

2. Izingxenye zokuxhuma

Isixhumi, esaziwa nangokuthi isixhumi esingaguquki, sinomthelela oqondile esakhiweni nasekuqineni kwemikhiqizo yefenisha. Isetshenziselwa ikakhulukazi ukuxhuma amaphaneli aseceleni, amaphaneli avundlile, namaphaneli angemuva efenisha yekhabhinethi ukulungisa amaphaneli efenisha. Induku yokuxhuma ihlanganisa izixhumi ze-eccentric nezixhumi ezihlala njalo.

1) Isixhumi se-Eccentric

Usebenzisa i-eccentric distance, xhuma ipuleti elivundlile ku-side plate, njengendawo yaphansi ne-side plate, futhi i-bottom plate ingafakwa ukusuka phezulu noma ohlangothini.

2) Izixhumi ezihlala njalo

Iqukethe izingxenye ezimbili: isikulufu kanye nomkhono onepuleti lensimbi yasentwasahlobo. Ngemva kokucindezela uxhumano ngesandla, into ixhunywe unomphela, ibonakala ngoxhumano oluqinile kakhulu.

3. Isilayidi sekhabethe

Ama-rails ama-slide ekhabethe ngokuvamile enziwa ngopende wokubhaka wensimbi noma izinto ezenziwe ngensimbi. Ngokwezindlela ezahlukene eMpumalanga China, zingahlukaniswa zibe uhlobo lwe-pulley noma uhlobo lwebhola. Ngokwebanga ukusuka ekhabetheni ukuya ekhabhinethi, zingahlukaniswa zibe yizinsimbi zesigaba esisodwa, izinsimbi eziphindwe kabili, nezinsimbi ezintathu.

4. Ibhawudi

Uhlobo lwe-fastener oluhlanganisa ikhanda nebhawodi (umzimba oyi-cylindrical onezintambo zangaphandle), odinga ukufaniswa nekhethini futhi usetshenziselwa ukuqinisa nokuxhuma izingxenye ezimbili ngezimbobo. Leli fomu lokuxhuma libizwa ngokuthi uxhumano lwe-bolt.

5. I-tendon eyindilinga

Enye yezinto ezisetshenziswa kakhulu zokuhlanganisa nokuxhuma ifenisha yephaneli, emise okwenduku eyindilinga futhi ngokuvamile yenziwe ngokhuni. Ekuhlakazweni nasekuhlanganiseni ifenisha, izintambo zokhuni zidlala indima yokumisa, ezinobubanzi obuvame ukusetshenziswa obungu-6mm, 8mm, 10mm, no-12mm, nobude obungu-20mm, 25mm, 30mm, 35mm, 40mm, no-50mm.

6. Ezinye izixhumi

Izikulufu, izikulufu zokuzithepha, amantongomane, amawasha, amawasha asentwasahlobo, amantongomane ayi-cylindrical, amantongomane anezimbambo ezimbili, izibambo, njll.

Isikhathi sokuthumela: May-09-2024