Kunezinhlobo eziningi zefenisha, njengefenisha yokhuni oluqinile, ifenisha yensimbi eyenziwe, ifenisha yamapuleti, njll. Ifenisha eminingi idinga ukuqoqwa ngabathengi ngokwabo ngemva kokuthenga. Ngakho-ke, lapho umhloli edinga ukuhlola ifenisha ehlanganisiwe, udinga ukuhlanganisa ifenisha esizeni, ngakho-ke yiziphi izinyathelo zemishini yokuqaqa nokuhlanganisa ifenisha, indlela yokusebenza esizeni, nokuthi yiziphi izinyathelo okufanele zithathwe. Ngezansi kukhona isifinyezo solunye ulwazi oluwusizo okufanele lukusize.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

1. Inani lokuhlolwa komhlangano endaweni 1) Umhloli kufanele ahlanganise okungenani isethi eyodwa yemikhiqizo ngokuzimela ngokwemiyalelo yomhlangano. Uma usayizi womkhiqizo mkhulu kakhulu, abasebenzi basefekthri kufanele basize, baqiniseke ukuthi ukuxhumeka kanye nezingxenye ezifanayo zifakiwe futhi ziqhutshwa ngumhloli ngokwakhe. 2) Ukuhlanganiswa kweminye imikhiqizo kungaqedwa ngabasebenzi basefekthri, kodwa kudinga ukuqedwa ngaphansi kokuqondisa komhloli kuyo yonke inqubo. Naka ukuhlola yonke inqubo yokuhlanganisa umkhiqizo, hhayi nje ukugxila kumphumela wokugcina womhlangano. Indoda yempahla ayikwazi ukushiya indawo yomhlangano, futhi inani lempahla liyadingeka ngokuhlola (WI).

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

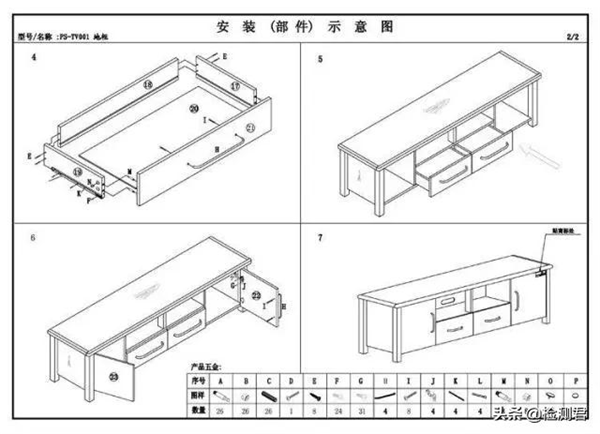

2.Izinyathelo zokuhlanganisa endaweni kanye nezinyathelo zokuphepha 1) Izinto zokusebenza endaweni kufanele zifakwe ngokuhambisana ngokuqinile nemiyalelo yomhlangano enikezwe umkhiqizo. Phakathi nenqubo yokuhlanganisa, hlola ukuthi izinyathelo zemiyalelo yomhlangano zilungile yini, ukuthi ingxenye ngayinye iyahlangabezana yini nezidingo zobuchwepheshe, noma ngabe ukulingana kuqinile, nokuthi izikhundla zembobo zilungile yini. , noma ngabe umkhiqizo uqinile, nokuthi udinga ukusebenzisa amathuluzi angaphandle (ngokuvamile akuvunyelwe, kuye ngezidingo zemanuwali) 2) Ngaphambi kokuhlanganisa, khomba inani lezingcezu zomkhiqizo, vula iphakethe lebhokisi, ubeke i-hardware. iphakheji endaweni ehlukile futhi ubale ukugwema ukulahleka noma ukuxutshwa nezisekeli ezivela kweminye imikhiqizo. 3) Okokuqala hlola ukuthi inombolo nosayizi wezingxenye kuyahambisana yini nenombolo ephawulwe encwadini, futhi qaphela ukuthi ungafaki esikhundleni izingxenye ezingafanele lapho uhlanganiswa. 4) Funda ngokucophelela imiyalelo yomhlangano, okokuqala uhlukanise izingxenye eziyinhloko ngokulandelana komhlangano, futhi uvakashele amaphaneli ngokwehlukana ukuze afakwe. Kungcono ukuthatha izithombe zalawa maphaneli.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

5) Lungiselela amathuluzi okufaka afana nama-screwdrivers, ama-wrenches, njll. Phakathi nenqubo yokuhlanganisa, landela ngokuqinile izinyathelo zomhlangano emiyalweni yokuhlanganisa umkhiqizo. Abahloli badinga ukunaka okukhethekile: abasebenzi basefekthri bavame ukuthembela kokuhlangenwe nakho phakathi nokuhlanganiswa, futhi bayehluleka ukufaka ngokuhambisana ngokugcwele nezinyathelo zemiyalelo. Le ndlela ayikwazi ukuhlola ukuthi imiyalelo yesisetshenziswa inengqondo futhi iphelele. Uma isimo esinjalo sitholakala, kufanele simiswe/silungiswe ngokushesha. Ngesikhathi esifanayo, kungcono ukufaka eyodwa ngayinye, hhayi eziningana ngesikhathi esisodwa, ukuze ungagadi endaweni. 6) Ngokuvamile, inqubo yokuhlanganisa imikhiqizo eminingi ingahlukaniswa ngezigaba ezine: Isinyathelo sokuqala ukwakha uhlaka lwamathambo omkhiqizo. Phakathi nale nqubo, kufanele kuqashelwe ukuthi izimbobo zokuxhuma ze-skeleton zilungile, nokuthi ngabe ukufakwa kwezinsimbi ezifana nama-bolts kubushelelezi, isixhumi kufanele sivalwe, futhi igebe lamathambo kufanele lifane. Ingxenye yesibili ukufaka izingxenye ezihleliwe nezihlanganisiwe zesakhiwo sokuqinisa ku-skeleton. Phakathi nale nqubo, qaphela izesekeli ze-hardware, ikakhulukazi izikulufa, ukuze zonke izingxenye nezinsimbi kufanele zibekwe, futhi uhlole ukuthi izimbobo zokuxhuma zifanelekile yini. Kumele kuqashelwe ukuthi isenzakalo sokuchithwa kwe-screw hole ngokuvamile kwenzeka kwinqubo yesibili. Ingxenye yesithathu ukufaka idivayisi yomhlahlandlela noma izingxenye ezihambayo ezixhunywe ngamahinji ezindaweni ezihambisanayo. Qaphela ukuthi ukuqaqa nokuhlanganiswa kwezingxenye zefenisha kungahlakazwa ngokuphelele futhi kuhlanganiswe izikhathi eziningi ngaphandle kokulimala. Kulesi sixhumanisi, kuyadingeka ukunaka ukuthi lezi zingxenye zixhunywe kanye. Kunezinkinga zezimbobo zesikulufa ezixegayo kanye nezingxenye ezilimele. Ingxenye yesine, ukufakwa kwezingxenye ezincane noma zokuhlobisa noma izesekeli. Phakathi nale nqubo, qaphela ukuthi ubude be-screw buhlangabezana nezidingo, noma ngabe izesekeli zokuhlobisa zingaqiniswa ngokuqinile, noma ngabe indawo yembobo ifanelekile uma ukhiya isikulufu, futhi umkhiqizo awukwazi ukuklwejwa ngesikhathi senqubo, kanye nezinsiza. ayikwazi ukuthukululwa.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

Izinkinga ezivamile 1. Kukhona izingxenye ezingekho emkhiqizweni, ikakhulukazi izesekeli ze-hardware ephaketheni elincane. Izimbobo zokufaka epuletini zigcwaliswa ngopende, futhi i-hardware ayikwazi ukufakwa kahle 4. Ukufakwa kwe-hardware akukwazi ukukhiywa, futhi umkhiqizo awuqinile 5. Uma ukhiya izinsimbi zehadiwe, izingxenye zikhubazekile, ziqhekekile, zonakalisiwe. , njll. 6 . Izingxenye ezihambayo ezisebenzayo azikwazi ukusunduzwa futhi zidonswe kahle. 7. Izingxenye zokuxhuma zonakalisiwe, futhi ubuso bezesekeli ze-hardware bugqwalile. 8. Igebe phakathi kwezingxenye phakathi nomhlangano likhulu kakhulu, noma igebe alilingani

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

Izidingo zekhwalithi yomkhiqizo nezindlela zokuhlola 1. Izindlela zokuhlola Ithuluzi lokulinganisa, ukuhlola okubonakalayo, ukuthinta ngesandla, hlola umkhiqizo ngokwezidingo zobuchwepheshe zokuhlanganiswa komkhiqizo kanye nosayizi womdwebo nesimo 2. Ibanga lokuhlola kufanele libe ngaphansi kokukhanya kwemvelo noma eduze nokukhanya kwemvelo ( isibonelo: isibani se-fluorescent esingu-40W), Ibanga lokubona 700-1000mm3. Ukukhathazeka kokuhlolwa kokubukeka 1) I-Welding, i-rivets, i-tenon joints, njll. esetshenziselwa izingxenye ezihleliwe akufanele ikhululeke. 2) Izikulufu nezingxenye zokuxhuma zehadiwe akufanele zikhululeke. I-3) Ingaphezulu lezesekeli ze-hardware alinawo ama-scratches, ungqimba oluhlanganisiwe (I-coating) luqinile, ngaphandle kokuwa noma ukugqwala. I-4) Izingxenye ezithwala imithwalo kanye nezingxenye ezihambayo akufanele zibe nemifantu, amafindo, izimbobo zezikelemu nezinye iziphambeko. 5) Izinsimbi zamapayipi ensimbi kufanele zingabi nemifantu kanye notwayi 7) Izingxenye ezishiselwe kufanele zingashisi, zingashisi futhi zingangeni 8) Izingxenye ezishiselwe kufanele zingabi nezimbotshana, zingabi nama-weld flash kanye nama-spatter. zidwetshwe kahle futhi ngaphandle kwezimpawu zesando 10) Ukugqoka akufanele kushise, amabhamuza, amaphinifa, imifantu, ama-burrs, ama-scratches 11) Ukumbozwa kwezingxenye zensimbi kufanele kungabi nangaphansi obala, ama-bumps, ukucwila okusobala, ama-bumps, imibimbi, upende ondizayo 12) Ingaphezulu lomkhiqizo ophelile alinawo imihuzuko, ukuklwebheka (ukuthinta) ) Ukulimala 13) I-overall isakhiwo somkhiqizo siqinile, umhlabathi ulinganisela, izingxenye azikhululekile lapho zinyakaziswa, ama-seams aqinile, futhi alikho igebe elisobala. 14) I-lens kanye nomnyango wengilazi kuhlanzekile futhi akunazimpawu zokunamathisela, futhi iglue noma ilunga liqinile futhi liqinile. I-16) Izingxenye zokhuni eziqinile azinakho ukubola, izimbobo zezikelemu, ukuqhekeka, njll., isiqondiso sombala nokusanhlamvu kwezinkuni kuyahambisana, futhi okuqukethwe komswakama kuhlangabezana nezidingo. 17) Ukumbozwa kwezingxenye zokhuni akufanele kube nokuvuza kwesikhumba Esishwabene nokuvuza kopende: Ukumbozwa noma ukunamathela kwezingxenye zensimbi kufanele kungabi nokuxebuka, ukufekethiswa, nokuvuza kopende. 18) Ukufakwa kwezingxenye zokhuni kufanele kube bushelelezi futhi bushelelezi, ngaphandle kwemihuzuko, amabala amhlophe, ama-bubbling, sagging, kanye nomehluko osobala wombala. 19) Akukho okungenalutho, okuxekethile, okudliwe ngamabhu, okuqhekekile, okuchotshoziwe, okuboshiwe, okubethelwe, okubhoboziwe, njll., akutholakali ezingxenyeni zephaneli. 20) Umbala ongaphezulu ufana, kungakhathaliseki ukuthi ucezu olulodwa lwezikhundla ezahlukene noma uhlelo lonke, umbala uyadingeka Ngokuvumelana 21) Awekho amamaki ethuluzi asobala, amamaki ommese, amamaki okuhudula, ukuqhekeka, ukuqhekeka, isihlabathi. black, sag Lungisa isicabha ukuze umnyango ugcine ushibilika 23) Ingilazi nezibuko akumele zinyakaziswe, zixege ngemva kokufaka Izidingo zomdwebo, usayizi wokubukeka ungaphakathi kosayizi ovunyelwe ukubekezelelana ububanzi

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

Izesekeli ezivamile ze-hardware zokuhlakaza kanye nokuhlanganiswa kwefenisha Izesekeli ze-Hardware ngokuvamile zisetshenziselwa ukulungisa nokuxhuma isakhiwo. Izixhumi ezivamile kufenisha zifaka amahinge, izixhumi (eccentric, permanent), amaslayidi ekhabetheni, amaslayidi eminyango eshelelayo, Izibambo, izingidi, amalashi, izinto zokudonsa izicabha, izisekelo zokuhlukanisa, iziphanyeko zezingubo, amapulley, izinyawo, amabhawudi, izikulufu zokhuni, amadowels, izinzipho eziyindilinga, njll.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

1. I-hinge hinge yisakhiwo esiyinhloko esixhuma izingxenye ezimbili ezihambayo, ezisetshenziselwa ikakhulukazi ukuvula nokuvala umnyango wekhabhinethi. Ihlukaniswe yaba ihinge evulekile kanye nehinge emnyama Ivuza phezu kwefenisha, futhi ihinji ingasetshenziselwa iminyango eyakhelwe ngaphakathi kanye nezicabha ezigoqayo.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

I-2) I-hinge efihliwe I-hinge efihliwe ijikeleziswa yinduku yokuxhuma, futhi ifihliwe ngaphakathi kwefenisha futhi ayivuzi ngesikhathi sokufakwa.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

2. Izixhumi Izixhumi zibizwa nangokuthi izixhumi ezingaguquki, ezinomthelela oqondile ekwakhiweni nasekuqineni kwemikhiqizo yefenisha. Ngokuyinhloko zisetshenziselwa ukuxhunywa kwamapaneli aseceleni, amaphaneli avundlile kanye namapaneli angemuva efenisha yekhabhinethi, ukuze amapaneli wefenisha angalungiswa. , induku yokuxhuma ihlanganisa ucezu lokuxhuma olungenasici kanye nocezu lokuxhuma unomphela. 1) Isixhumi se-eccentric sithatha ibanga eliqondile ukuze sixhume ipuleti elivundlile kanye ne-side plate, njengephansi kanye ne-side plate, futhi ipuleti elingezansi lingafakwa ukusuka phezulu noma ukusuka eceleni.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

2) Isixhumi esihlala njalo sakhiwe izingxenye ezimbili: isikulufu kanye nomkhono ngeshidi lensimbi yasentwasahlobo. Ngemuva kokuthi uxhumano lucindezelwe ngesandla, into ixhunywe unomphela, ebonakala ngokuxhuma okuqinile kakhulu.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

3. Amaslayidi ekhabethe Amaslayidi ekhabethe ngokuvamile enziwa nge-varnish yokubhaka kwensimbi noma ngezinto ezenziwe ngamathayela ensimbi. Ngokwezindlela ezahlukene e-East China, zingahlukaniswa zibe uhlobo lwe-pulley noma uhlobo lwebhola, njll Ngokusho kwebanga le-drawer edonsa ngaphandle kwekhabhinethi, lingahlukaniswa libe yi-single section Track, ithrekhi ephindwe kabili, ithrekhi kathathu.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

4. Uhlobo lwe-fastener oluhlanganisa ikhanda nebhawodi (isilinda esinentambo yangaphandle), edinga ukufaniswa nekhethini ukuze kuhlanganiswe nokuxhuma izingxenye ezimbili ngezimbobo. Leli fomu lokuxhuma libizwa ngokuthi ukuxhumana okuboshiwe.

5. Ifenisha ye-round rod kanye ne-tenon board ingenye yezinto ezisetshenziswa kakhulu zokuhlanganisa nokuxhuma. Ukuma kwayo kufana nenduku eyindilinga. Ngokuvamile kwenziwa ngokhuni. I-tenon yokhuni ku-disassembly kanye nefenisha yomhlangano idlala indima yokubeka. Amadayamitha asetshenziswa kakhulu yi-6mm, 8mm, 10mm, 12mm, Ubude buyi-20mm, 25mm, 30mm, 35mm, 40mm, 50mm.

Izinyathelo zemishini kanye nezidingo ezibalulekile zokuhlolwa kwefenisha

6. Ezinye izikulufu zokuxhuma, izikulufu ezizithephayo, amantongomane, amawasha, amawasha asentwasahlobo, amantongomane angama-cylindrical, amantongomane ezintambo ezimbili, izibambo, njll.

Isikhathi sokuthumela: Jul-19-2022