Lapho uthekelisa, okukhathaza kakhulu amabhizinisi avamile phakathi nenqubo yokulayisha idatha yempahla engalungile, ukulinyazwa kwempahla, nokungahambisani phakathi kwedatha nedatha yokumenyezelwa kwempahla, okuholela ekutheni amasiko angazikhiphi izimpahla. Ngakho-ke, ngaphambi kokulayisha, umthumeli, indawo yokugcina impahla, kanye nomthumeli wezimpahla kumele baxhumanise ngokucophelela ukugwema lesi simo.

I-Cargo Inventory 1

1. Yenza uhlu lwasendaweni ngohlu lokupakisha lwekhasimende, futhi uqinisekise ukuthi ubuningi bomkhiqizo, inombolo yeqoqo, kanye nezinsiza kuyahambisana nohlu lokupakisha lwekhasimende. 2. Ukupakishwa kwempahla kuyahlolwa ukuze kuhlangabezane nezidingo zamakhasimende futhi kungavikela impahla ngesikhathi sokuthutha. 3. Hlola imininingwane yesiqukathi yokulayisha ukuze uqinisekise ukuthi inombolo yesiqukathi, inqwaba yomkhiqizo, nolwazi lokupakisha kuyahambisana futhi kuyinqwaba yokuthunyelwa ehleliwe.

Ukuhlolwa kwesitsha 2

1. Uhlobo lwesiqukathi: Iziqukathi ezithobela amazinga e-ISO 688 kanye ne-ISO 1496-1.

2. Osayizi abavamile: Ikhabhinethi engamamitha angu-20, ikhabethe eliyizinyawo ezingu-40 noma ikhabethe eliphakeme elingamafidi angu-40.

3. Hlola ukuthi isiqukathi sifanelekile yini noma cha.

#a. Ukuhlolwa kwangaphandle kwesiqukathi

①. Isiqukathi kufanele siphathe inombolo evumelekile enezinhlamvu ezingu-11 ethobelana nezidingo ze-IQS 6346.

②. Iziqukathi kufanele zibe ne-nameplate yokuphepha yesiqukathi esivumelekile (i-CSC nameplate).

③. Awekho amalebula azinamathelayo (njengamalebula ezimpahla eziyingozi) ashiywe iqoqo langaphambili lempahla.

④. Iminyango yeKhabhinethi kufanele isebenzise i-hardware yokuqala yokuhlanganisa futhi ingalungiswa nge-epoxy resin.

⑤.Ilokhi yomnyango isesimweni esihle.

⑥. Ukuthi kukhona ukukhiya kwempahla (ephathwa umshayeli wesitsha).

# b.Ukuhlolwa kwangaphakathi kwesiqukathi

①.Yome ngokuphelele, ihlanzekile futhi ayinaphunga.

②.Izimbobo zokungenisa umoya azikwazi ukuvinjelwa.

③. Azikho izimbobo noma imifantu ezindongeni ezine, ungqimba olungaphezulu, nangaphansi.

④. Izindawo zokugqwala nama-indentation akufanele kudlule ama-80 mm.

⑤. Azikho izipikili noma ezinye iziqhumane ezingalimaza impahla.

⑥. Awukho umonakalo endaweni yokubopha. ⑦.Ingangeni manzi.

#c. Ukuhlolwa kwe-Cargo Pallet

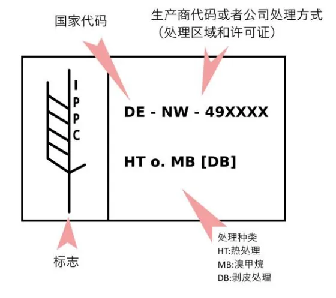

I-pallets yokhuni kufanele ibe nayoizitifiketi zokufuthwafuthiizitifiketi ze-phytosanitary, ingafakwa imfologo kuzo zonke izinhlangothi, futhi ibe namaphalethi alashiwe angu-3:

#Indlela engcono kakhulu yokusebenzisa amaphalethi

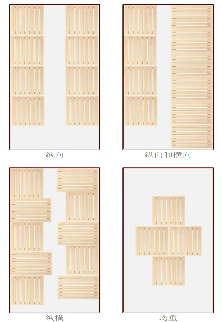

①.Uma izimpahla ezifanayo zibekwe kuphalethi efanayo, uhlobo olugqagqene lungcono kunohlobo oluyaluzayo.

Ngenxa yokuthi uhlobo oluyaluzayo lunyakaza kancane lapho lunyakaza, uhlobo olugqagqene lungagcizelela ngokulinganayo amakhona amane nezindonga zebhokisi, ngaleyo ndlela kuthuthukiswe umthamo wokuthwala.

②.Beka izimpahla ezisinda kakhulu ngezansi futhi uzigcine zihambisana nomkhawulo wephalethi.

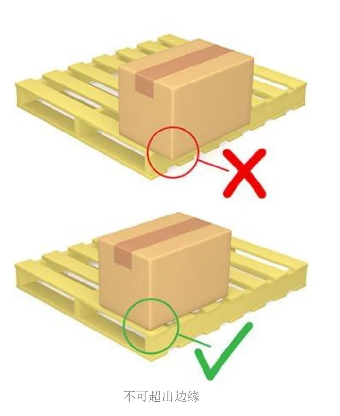

③.Izimpahla akufanele zeqe unqenqema lwephalethi ukuze zigweme ukonakala kalula ngesikhathi sokuthutha nokulayisha nokuthulula.

④. Uma ungqimba olungaphezulu lwephalethi lungagcwele, beka amabhokisi emaphethelweni angaphandle ukuze ukhulise ukuzinza futhi ugweme ukunqwabelana kwephiramidi ngangokunokwenzeka.

⑤. Kunconywa ukuvikela imiphetho yezimpahla ngekhadibhodi. Sebenzisa ifilimu enwetshiwe ukugoqa i-pallet ngokuqinile ukusuka phezulu kuye phansi, futhi ubophe i-pallet ngebhande lenayiloni noma lensimbi. Ukubopha kufanele kuzungeze phansi kwe-pallet futhi kugweme ukugoqa.

⑥. Ezokuthutha zasolwandle: izimpahla ze-palletized ezingapakishwanga azikho ngaphezu kuka-2100 mm. Ezokuthutha komoya: Izimpahla ezinephalethi azikho ngaphezu kuka-1600 mm.

Ukulayisha impahla esitsheni 3

Ukuvikela ukuthi impahla ingalinyazwa ngenxa yokuzamazama, ukudlidliza, ukugingqika, ukugingqika, nokuchezuka ngesikhathi sokuthutha. Udinga ukwenza lokhu okulandelayo:

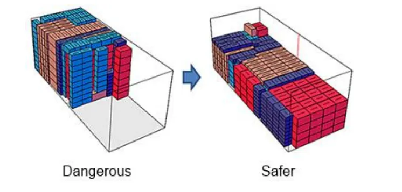

#a. Qinisekisa ukuthi isikhungo se-gravity siphakathi kwesiqukathi futhi isisindo aseqeli umthamo wokuthwala wesiqukathi.

(Izimpahla ezifakwe ngephalethi)

(Izimpahla ezingezona i-palleted)

Uma isiqukathi singagcwele, zonke izimpahla azikwazi ukubekwa ngemuva kwempahla ukuze kubangele isikhungo sokudonsela phansi sibuyele emuva. Ukugudluzwa ngemuva kwenkaba yamandla adonsela phansi kungase kubangele ukulimala kwabantu eduze kwempahla, futhi impahla ingase iwe lapho ukuvulwa komnyango, kube yingozi kubasebenzi abehlisayo, futhi kungase kulimaze noma kucekele phansi impahla kanye nenye impahla.

#b. Ukunqwabelana kwempahla nokuqiniswa

#c. Sekela umthwalo ngokugcwele, gcwalisa izikhala ukuvimbela ukukhukhuleka komthwalo, futhi ugweme ukumosha okungadingekile kwesikhala sesitsha.

Ukulayishwa kwempahla kuqediwe 4

#a. Ngemva kokulayisha isitsha, thatha izithombe noma amavidiyo ukuze urekhode isimo sezimpahla phambi komnyango wesiqukathi.

#b. Vala umnyango wesitsha, uwuvale, bese ubhala inombolo yophawu kanye nenombolo yesiqukathi.

#c. Hlela imibhalo efanele futhi uthumele imibhalo kanye nokupakisha imidwebo yekhabhinethi nge-imeyili eminyangweni efanele yenkampani kanye namakhasimende ukuze kugcinwe amarekhodi.

Isikhathi sokuthumela: May-28-2024